Microbial fuel cell and application thereof to degradation of azo dye pollutant

A technology of fuel cells and microorganisms, which is applied in the fields of biochemical fuel cells, fuel cells, battery electrodes, etc., and can solve the problems of high energy consumption and difficult realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

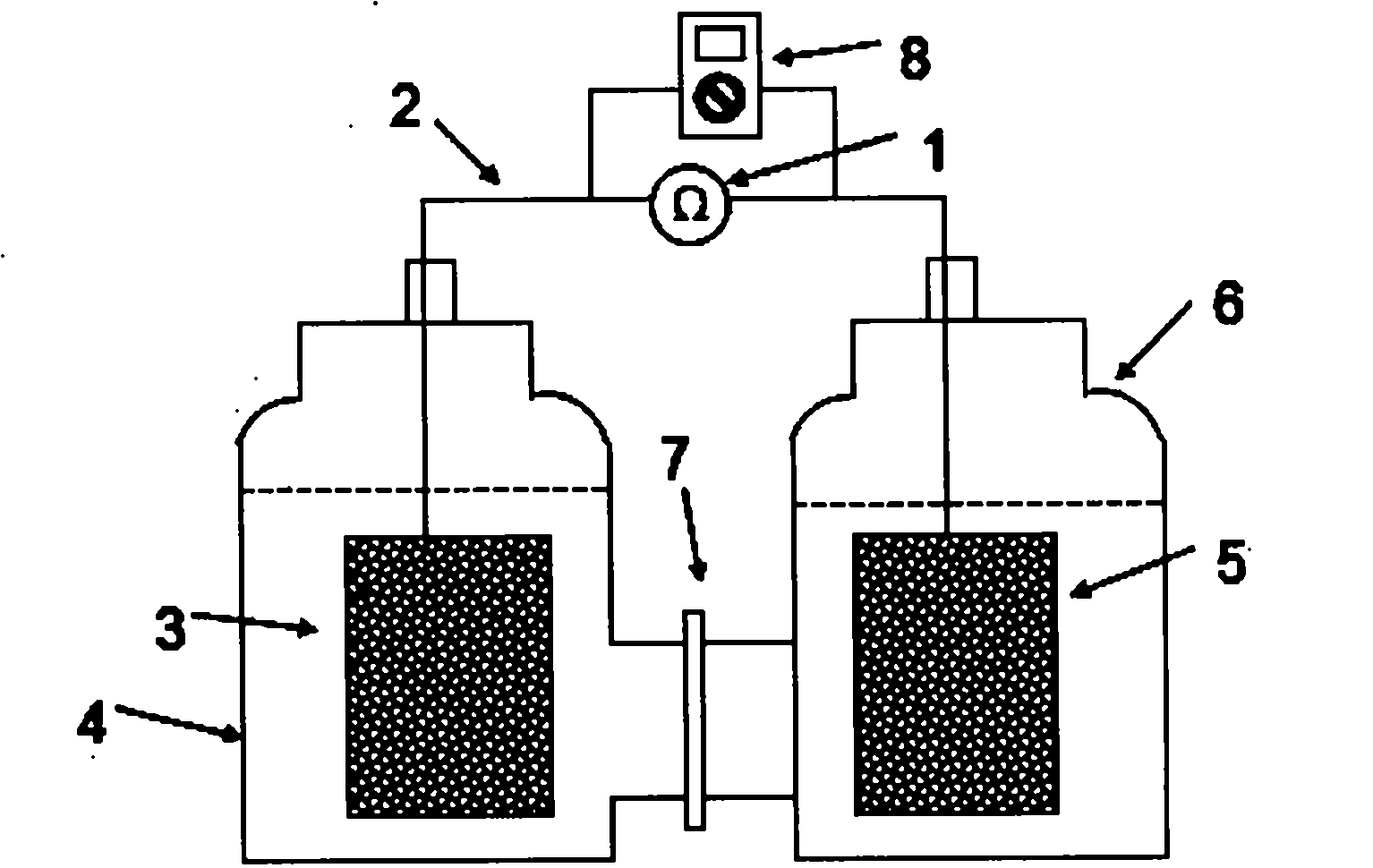

[0021] Step 1: Build a microbial fuel cell, such as figure 1 As shown: the anode chamber 4 and the cathode chamber 6 are made of glass, with a volume of 250 ml, separated by a Nafion 112 selective proton permeable membrane 7 .

[0022] Step 2: Put the anode electrode 3 and the cathode electrode 5 into the anode chamber 4 and the cathode chamber 6 respectively, and the electrode material of the anode electrode 3 and the cathode electrode 5 is 2.5×4cm 2Carbon paper (Toray, Japan), connect the anode electrode 3 and the cathode electrode 5 through the external circuit wire 2, connect the external resistance 1 of 1000 ohms to the external circuit wire 2 to reflect the electricity production situation, and connect the multimeter 8 to collect the electricity production data .

[0023] Step 3: Add 200ml of culture solution to the anode chamber and the cathode chamber respectively, and its composition is: improved M9 inorganic salt solution (5.7mmol / L Na 2 HPO 4 12H 2 O, 3.3mmol / L ...

Embodiment 2

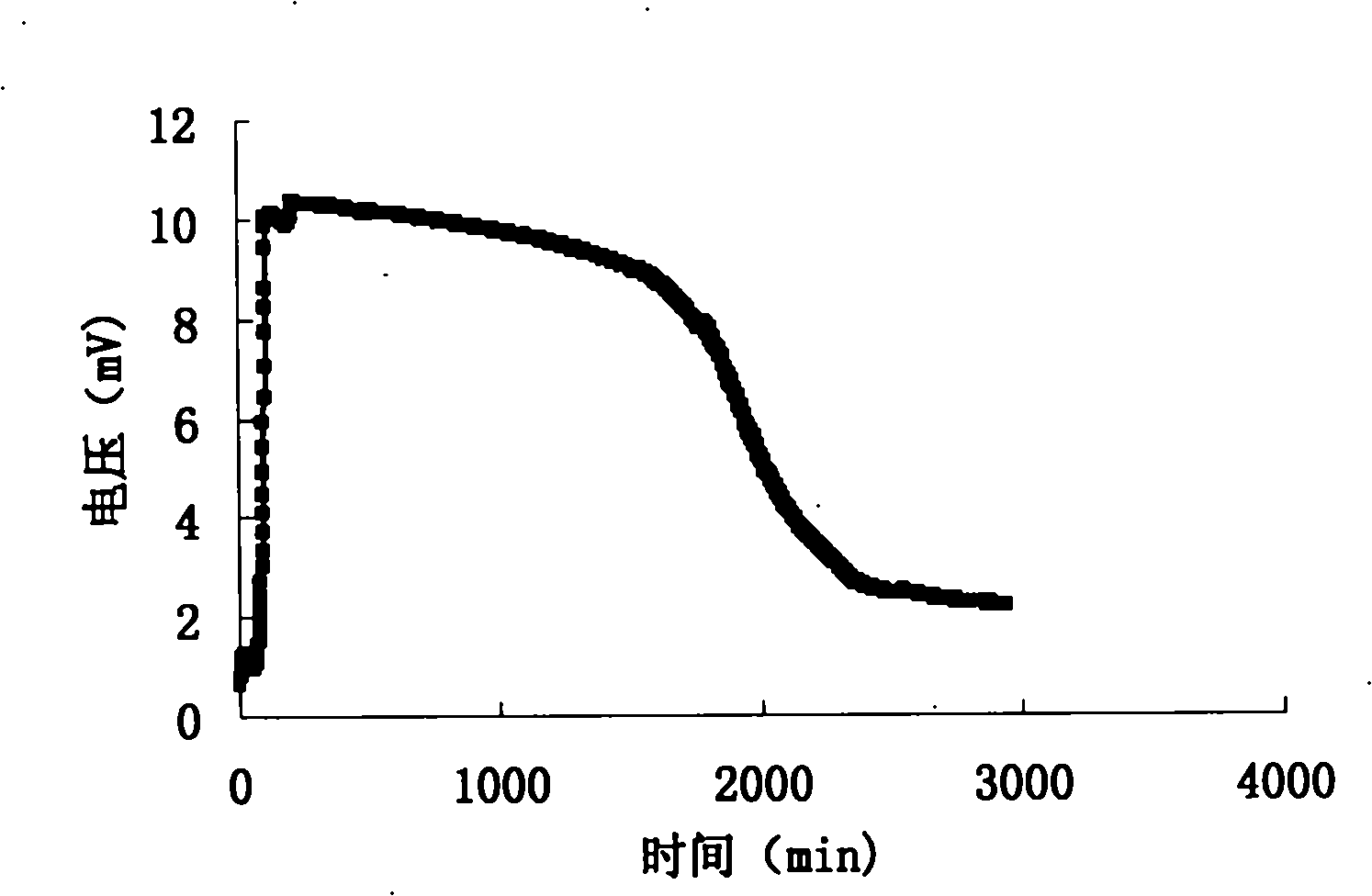

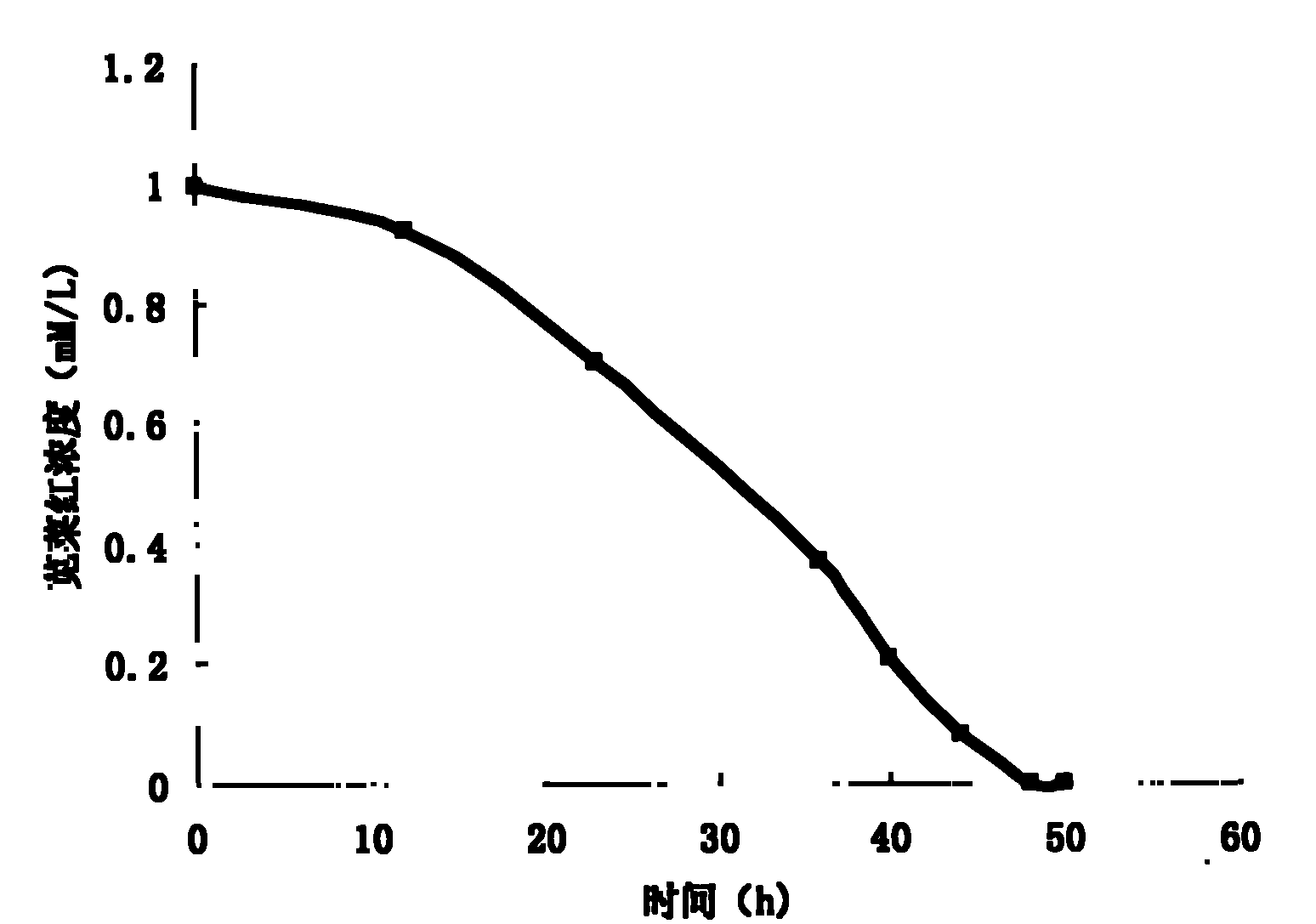

[0029] The operation method of this embodiment is basically the same as that of Embodiment 1, except that 0.5 mmol of azo dye amaranth is added into the cathode chamber as an electron acceptor.

[0030] The results show that: due to the lower concentration of the azo dye as the final electron acceptor in the cathode, the highest output voltage of MFC is 3mV. At the same time, due to the low concentration of the azo dye, the decolorization reaction is completed in a short time, and it takes about 36 hours to completely reduce the azo dye amaranth.

[0031] The microbial fuel cell of this embodiment does not need to provide an additional external power supply to balance the electrodes in the working device at a fixed potential during the entire process of reducing and degrading the azo dye amaranth, so that the azo dye amaranth can be efficiently and thoroughly degraded. Red is completely restored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com