Anti-electromagnetic-resistance high-power system power supply

A technology of anti-electromagnetic interference and system power supply, which is applied in the direction of high-efficiency power electronic conversion, output power conversion device, electrical components, etc., can solve the problems of serious high-power system power supply, reduce the efficiency of the whole machine, and unfavorable production, etc., to solve the problem of system Effects of EMI problems, reduction of interference sources, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

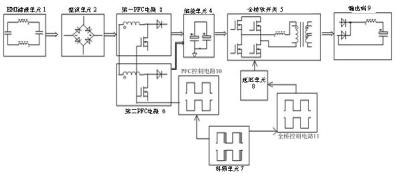

[0015] Such as figure 1 As shown, the anti-electromagnetic interference high-power system power supply includes an EMI filter unit 1, an energy storage unit 4 and a full-bridge soft switch 5. The output end of the EMI filter unit 1 is connected to the rectifier unit 2, the first PFC circuit 3 and the second PFC The circuit 6 is connected to the output end of the rectification unit 2 in parallel, the output end of the first PFC circuit 3 and the output end of the second PFC circuit 6 are connected to the energy storage unit 4, and the energy storage unit 4 is connected to the output through the full-bridge soft switch 5 Terminal 9, the frequency shaking unit 7 is connected to the PFC control circuit 10, the PFC control circuit 10 is connected to the first PFC circuit 3 and the second PFC circuit 6, the frequency shaking unit 7 is also connected to the full bridge control circuit 11, and the full bridge control circuit 11 is connected to the delay unit 8. The delay unit 8 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com