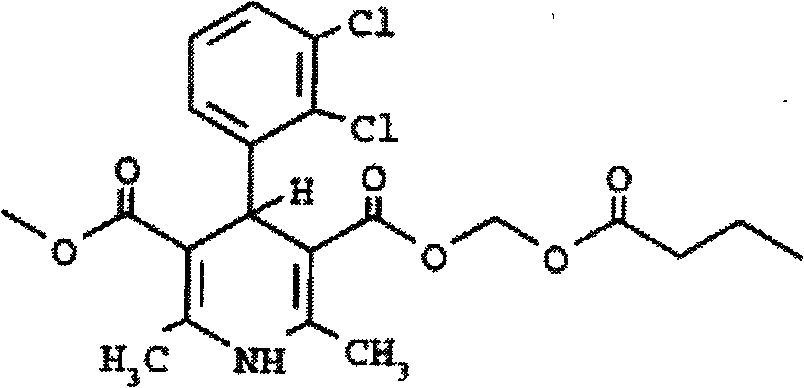

Clevidipine butyrate structured lipid emulsion and preparation method thereof

A kind of technology of clevidipine butyrate and fat emulsion, which is applied in the directions of oil/fat/wax inactive ingredients, pharmaceutical formulations, emulsion delivery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

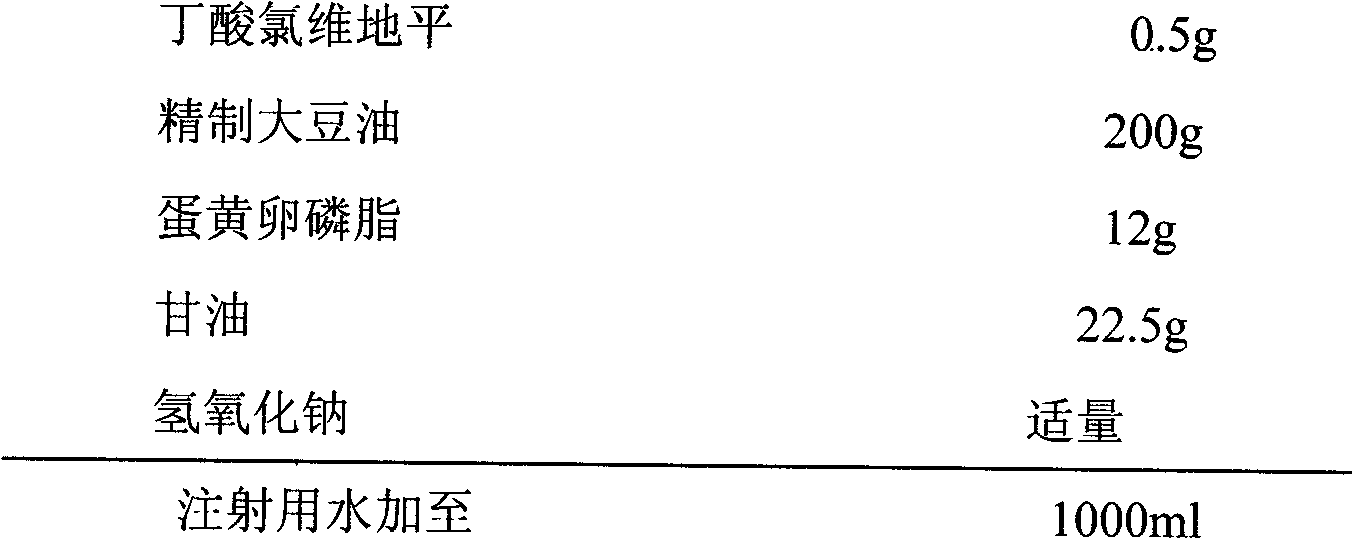

Embodiment 1

[0033] prescription

[0034]

[0035] Process:

[0036] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 75°C, and set aside;

[0037] (2) Preparation of oil phase: heat refined soybean oil to 75°C, add egg yolk lecithin (with a phosphatidylcholine content of more than 80%) to dissolve, add clevidipine butyrate, and stir to dissolve;

[0038] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 75° C., high-speed shear dispersion, shear speed of 8000 rpm, and time of 15 minutes to form colostrum;

[0039] (4) Adjusting the pH value: rapidly cooling the colostrum in step (3) below 30°C, and adjusting the pH value to 6.0-8.0 with sodium hydroxide;

[0040](5) High-pressure homogenization: the colostrum in step (4) is homogenized under high pressure by a microfluidizer 4 times, the pressure is 1000 bar, and the temperature is controlled below 30°C;

[0041] (6) potting and sterilization: ...

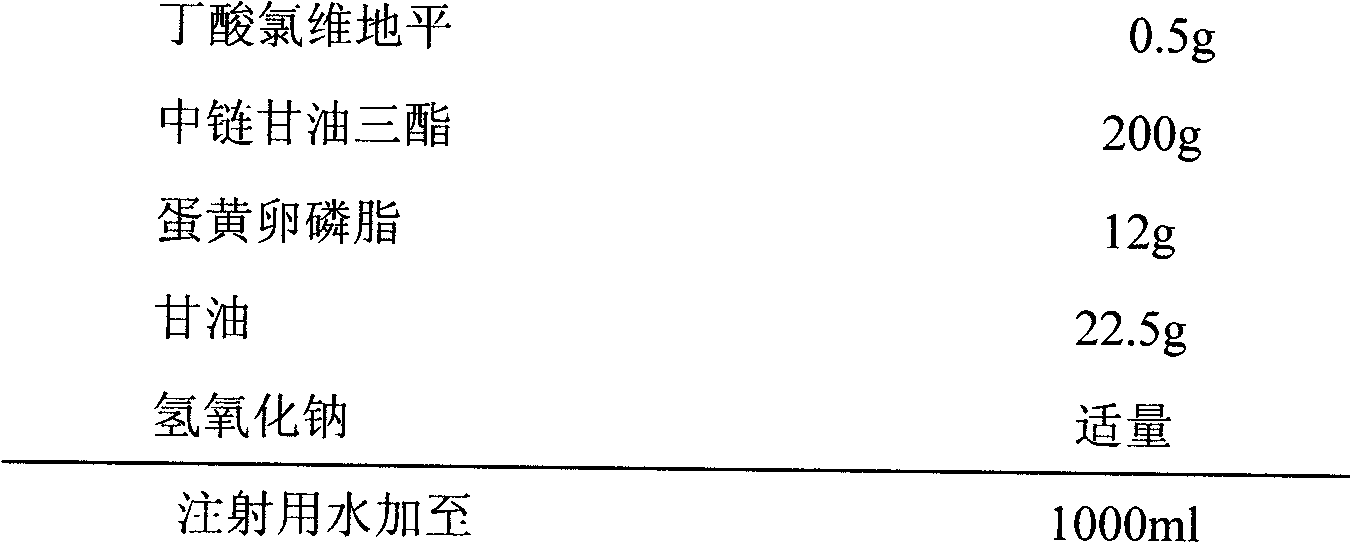

Embodiment 2

[0044] prescription

[0045]

[0046] Process:

[0047] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 75°C, and set aside;

[0048] (2) Preparation of oil phase: heat refined soybean oil to 75°C, add egg yolk lecithin (with a phosphatidylcholine content of more than 80%) to dissolve, add clevidipine butyrate, and stir to dissolve;

[0049] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 75° C., high-speed shear dispersion, shear speed of 8000 rpm, and time of 15 minutes to form colostrum;

[0050] (4) Adjusting the pH value: rapidly cooling the colostrum in step (3) below 30°C, and adjusting the pH value to 6.0-8.0 with sodium hydroxide;

[0051] (5) High-pressure homogenization: the colostrum in step (4) is homogenized under high pressure by a microfluidizer 4 times, the pressure is 1000 bar, and the temperature is controlled below 30°C;

[0052] (6) potting and sterilization:...

Embodiment 3

[0055] prescription:

[0056]

[0057] Process:

[0058] (1) Preparation of water phase: add glycerin to water to dissolve, heat to 75°C, and set aside;

[0059] (2) Preparation of oil phase: heat refined soybean oil and medium-chain triglycerides to 75°C, add egg yolk lecithin (more than 80% phosphatidylcholine content) to dissolve, add clevidipine butyrate, and stir to make it dissolve;

[0060] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 75° C., high-speed shear dispersion, shear speed of 8000 rpm, and time of 15 minutes to form colostrum;

[0061] (4) pH value adjustment: quickly cool down the colostrum in step (3) to below 30°C, and adjust the pH value to 4.5-6.5 with sodium hydroxide;

[0062] (5) High-pressure homogenization: the colostrum in step (4) is homogenized under high pressure by a microfluidizer 4 times, the pressure is 1000 bar, and the temperature is controlled below 30°C;

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com