Improved method for manufacturing high-frequency heated bamboo/wood recombined material

A manufacturing method and high-frequency heating technology, applied in manufacturing tools, wood-layered products, chemical instruments and methods, etc., can solve the problems of large heat dissipation on the surface of the slab, poor curing of the adhesive, and inability to continue heating. Low frequency, high production efficiency, and economical and reasonable energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

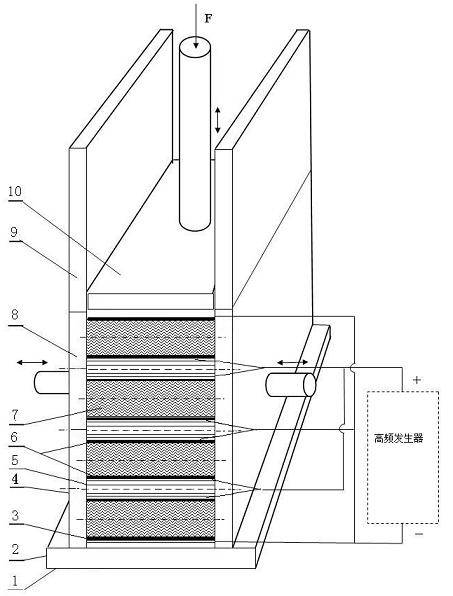

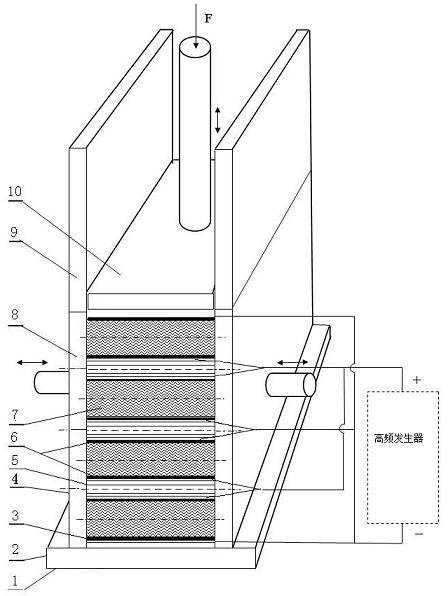

[0023] Embodiment 1: The load of bamboo and wood is connected in parallel in the high-frequency oscillation circuit of the high-frequency generator; the press adds 1 to 3 positive middle pressure plates and 0 to 2 negative middle pressure plates, and places the positive plate 4 and the negative plate 3 in the middle On the upper and lower surfaces of the pressure plate 5, the negative middle pressure plate is arranged alternately between the positive middle pressure plate, and the upper pressure head 10 of the press machine and the lower frame pressure plate 1 are both negative electrodes, and the heat insulating material is filled between the pole plate and the pressure plate. During processing, the middle pressure plate 5 Place a piece of bamboo or wood plywood slab 7 between the middle platen 5 and the lower frame platen 1 and the upper press head 10 of the press, so that the high-frequency press can glue 2 to 6 Bamboo reconstituted timber, wood recombined timber or bamboo-w...

Embodiment 2

[0029] Example 2: High-frequency hot-press bonding, drying thin bamboo strips with a thickness of 1.2mm, a width of 15mm, and a length of 3.1m to a moisture content of 8-10%, 5 impregnation with phenolic resin (diluted to a solid content of 25%), the amount of impregnation 7% (the ratio of the absolute dry weight of resin and the absolute dry weight of bamboo strips), other is with embodiment 1.

[0030] The physical and mechanical properties of thin bamboo strip reconstituted wood are as follows:

[0031] Size: 3.0m×800mm×150mm

[0032] Density: 0.95~1.1g / cm 3

[0033] MOR∥: ≥120MPa

[0034] MOE∥: ≥11000MPa

Embodiment 3

[0035] Embodiment 3: High-frequency hot-pressing glue, the above-mentioned bamboo strips are processed according to the method described in Embodiment 1; the width of the wooden veneer is about 15mm, the thickness is 1.5-2mm, and the length is 2.6m, dried to a moisture content of 8%, dipped in glue , Dry at low temperature until the moisture content is 8-14%, and then according to the density of 1.0g / cm 3 Calculate and weigh, weigh according to the ratio of bamboo strips and wooden veneer strips (weight ratio) 2:1 (weight ratio), and mix evenly, lay evenly on the pre-pressing baler in the same direction, and start the hydraulic system of the pre-pressing baler after laying, The pressure plate is pressed to the specified pressure, and after compression, it is fastened with plastic straps. During hot pressing, hoist 4 packages into the feeder at the same time, and transport them into the high-frequency heating press at the same time by mechanical means; start the hydraulic stati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com