Zinc-bismuth based perovskite-lead titanate-lead based relaxor ferroelectric ternary system piezoceramics and preparation method thereof

A technology of piezoelectric ceramics and perovskite, which is applied in the field of electronic component manufacturing to achieve the effects of low lead content, lower sintering temperature, and excellent piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Carry out each step sequentially according to the above-mentioned embodiment mode, the general composition formula of the piezoelectric ceramic of the present embodiment is:

[0049] 0.05PbTiO 3 +0.05Bi(Zn 2 / 3 Nb 1 / 3 )O 3 +0.9Pb(Zn 1 / 3 Nb 2 / 3 )O 3 .

[0050] In step 2, the calcination temperature is 850° C., and the calcination time is 2 hours.

[0051] In step 3, the wet ball milling time is 12 hours.

[0052] In step 4, the sintering temperature is 1050° C., and the sintering time is 2 hours.

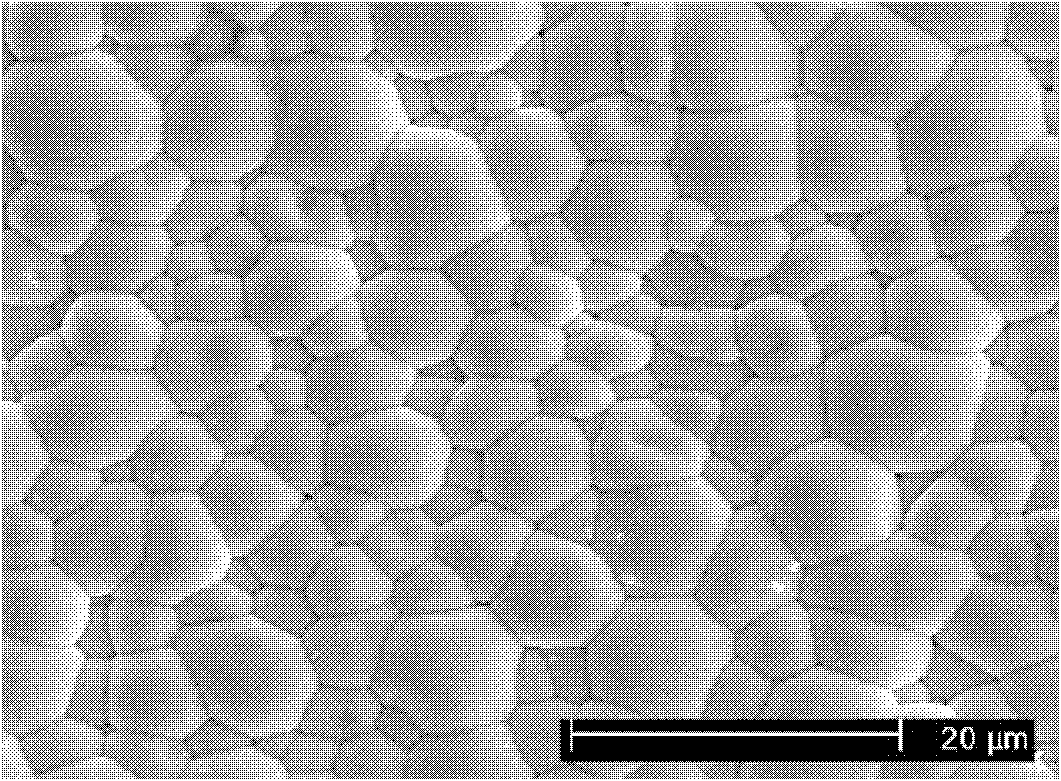

[0053] The scanning electron micrograph of the natural surface of the piezoelectric ceramic prepared in this embodiment is as follows: figure 1 As shown, other physical properties of the sample were measured: the Curie temperature was 230° C., the dielectric constant was 1170 (1 kHz), the piezoelectric constant was 550 pC / N, and the planar electromechanical coupling coefficient was 68%.

Embodiment 2

[0055] Carry out each step sequentially according to the above-mentioned embodiment mode, the general composition formula of the piezoelectric ceramic of the present embodiment is:

[0056] 0.995[0.05PbTiO 3 +0.05Bi(Zn 2 / 3 Nb 1 / 3 )O 3 +0.9Pb(Zn 1 / 3 Nb 2 / 3 )O 3 ]+0.005CuO.

[0057] In step 2, the calcination temperature is 850° C., and the calcination time is 2 hours.

[0058] In step 3, the wet ball milling time is 12 hours.

[0059] In step 4, the sintering temperature is 1020° C., and the sintering time is 2 hours.

[0060] The physical properties of the piezoelectric ceramics prepared in this embodiment: the Curie temperature is 232° C., the dielectric constant is 1010 (1 kHz), the piezoelectric constant is 500 pC / N, and the planar electromechanical coupling coefficient is 65%.

Embodiment 3

[0062] Carry out each step sequentially according to the above-mentioned embodiment mode, the general composition formula of the piezoelectric ceramic of the present embodiment is:

[0063] 0.2PbTiO 3 +0.2Bi(Zn 0.5 Ti 0.5 )O 3 +0.6Pb(Mg 1 / 3 Nb 2 / 3 )O 3 .

[0064] In step 2, the calcination temperature is 850° C., and the calcination time is 2 hours.

[0065] In step 3, the wet ball milling time is 12 hours.

[0066] In step 4, the sintering temperature is 1050° C., and the sintering time is 2 hours.

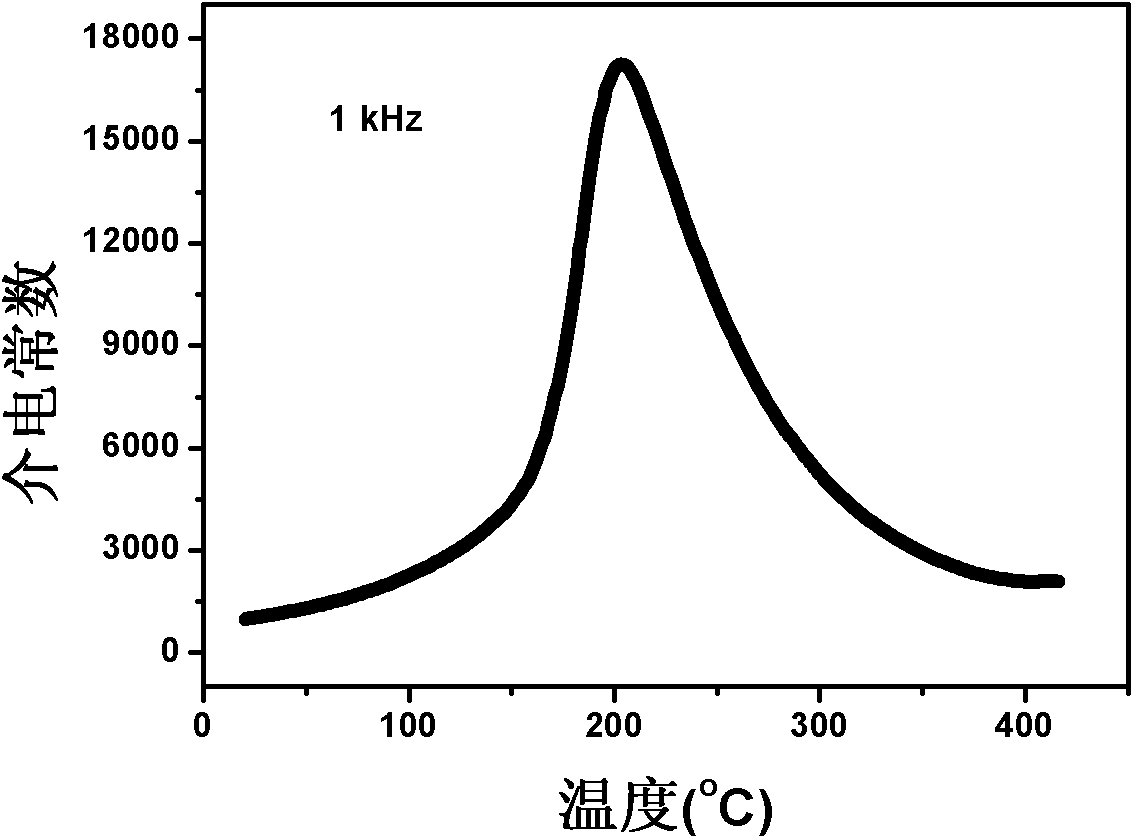

[0067] The dielectric temperature curve of the piezoelectric ceramic prepared in this embodiment is as follows figure 2 As shown, other physical properties of the sample were measured: the Curie temperature is 210° C., the dielectric constant is 870 (1 kHz), the piezoelectric constant is 490 pC / N, and the planar electromechanical coupling coefficient is 61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com