Method for preparing composite slow-release fertilizer by common utilization of biomass and sludge

A biomass and slow-release fertilizer technology, applied in the field of resource utilization of compound slow-release fertilizer, to avoid soil pollution, strong process adaptability and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

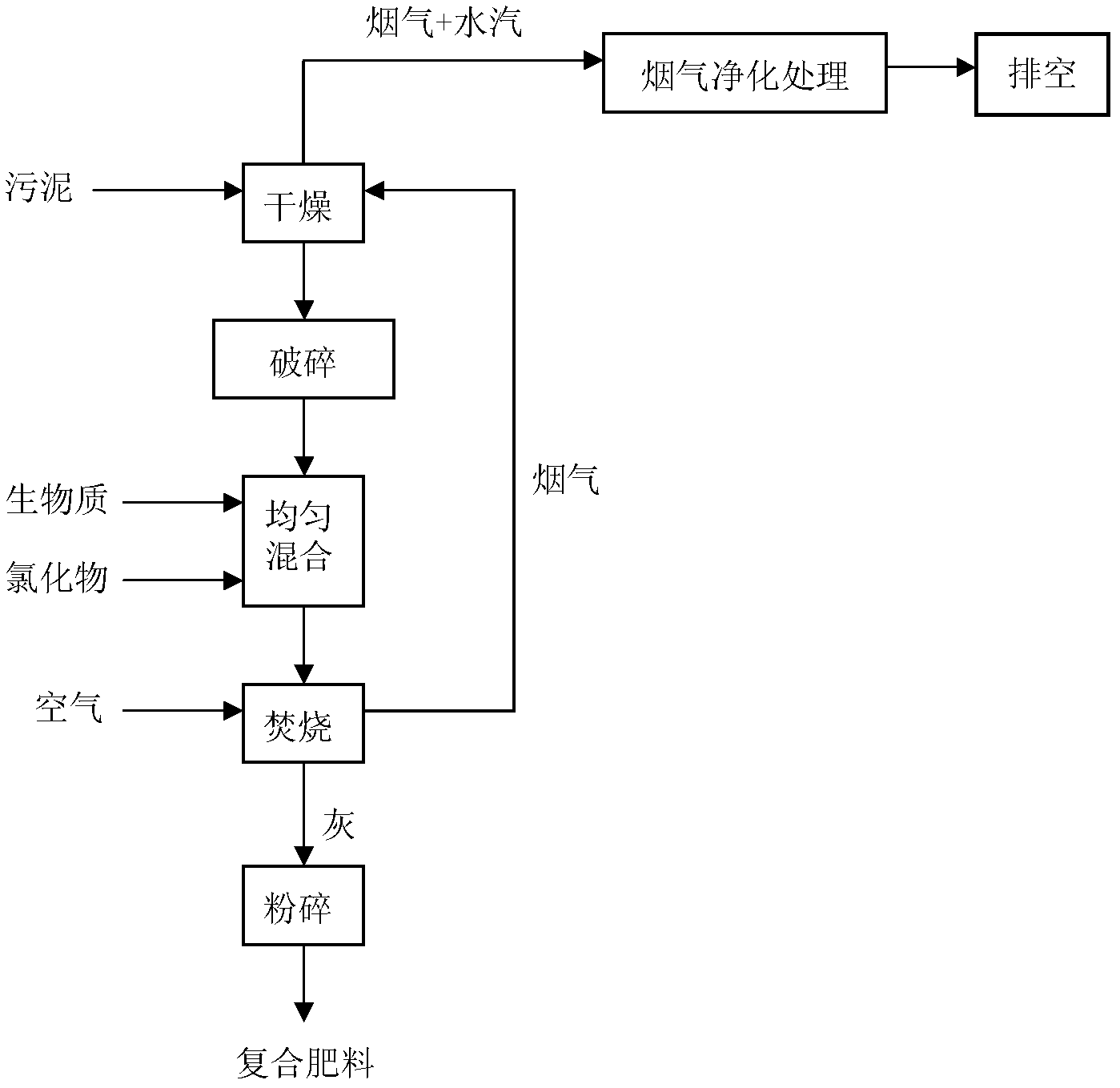

[0030] In this example, the method of producing compound slow-release fertilizer by co-utilization of biomass and sludge is as follows, and the flow chart is shown in figure 1 , the process includes the following steps:

[0031](1) The sludge is first dried indirectly with flue gas at 650°C, and then the bulk sludge is crushed, and the evaporated water vapor is mixed with the flue gas and then emptied after being treated by the flue gas purification system;

[0032] (2) The dried sludge is fully and evenly mixed with biomass powder and chloride in a mixing device;

[0033] (3) passing the mixture obtained in step (2) into a reaction furnace for high-temperature incineration, and the high-temperature flue gas produced by incineration is used for sludge drying in step (1);

[0034] (4) The solid product in the step (3) is crushed and sieved to obtain a compound fertilizer.

[0035] The moisture content of the sludge described in step (1) is 74.3%. During the drying process, th...

Embodiment 2

[0043] In this example, the method of producing compound slow-release fertilizer by co-utilization of biomass and sludge is as follows, and the flow chart is shown in figure 1 :

[0044] The sludge with a moisture content of 80% is indirectly dried with flue gas at a temperature of 700°C. During the drying process, the temperature of the sludge is basically maintained at about 170°C, and the drying time is 30 minutes. The moisture content of the sludge after drying is measured to be 16%. . During the drying process, the organic matter in the sludge basically did not decompose, and the high-potential heat value of the obtained dried sludge was 8.9MJ·kg -1 . The dried sludge lumps were mechanically crushed to obtain sludge fragments with an average particle size of about 0.5 cm. The water vapor evaporated during the sludge indirect drying process is mixed with the flue gas, and after being treated by the flue gas purification system, it is discharged to the atmosphere through...

Embodiment 3

[0046] In this example, the method of producing compound slow-release fertilizer by co-utilization of biomass and sludge is as follows, and the flow chart is shown in figure 1 :

[0047] The sludge with a moisture content of 70.8% was indirectly dried with flue gas at a temperature of 500°C. During the drying process, the temperature was basically maintained at about 150°C, and the drying time was 90 minutes. The moisture content of the sludge after drying was measured to be 9%. During the drying process, the organic matter in the sludge basically did not decompose, and the high-level heat value of the obtained dried sludge was 10.3MJ kg -1 . The dried sludge lumps were broken to obtain sludge fragments with an average particle size of about 0.5 cm. The water vapor evaporated during the sludge indirect drying process is mixed with the flue gas and discharged into the atmosphere after being treated by the flue gas purification system. The waste gas treatment process is the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com