Fluorine-silicon acrylic resin nano composite anti-icing coating and preparation method thereof

A technology of fluorosilicone acrylic and acrylic resin, applied in the direction of coating, etc., can solve problems such as high cost, unsuitable for large-scale use, complex technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

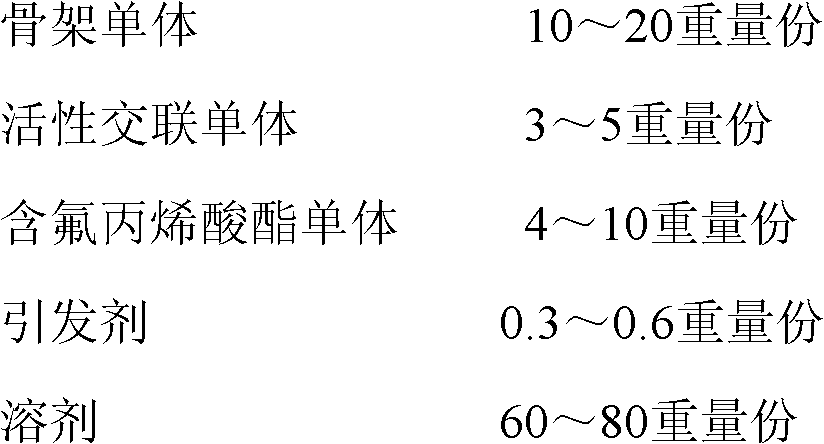

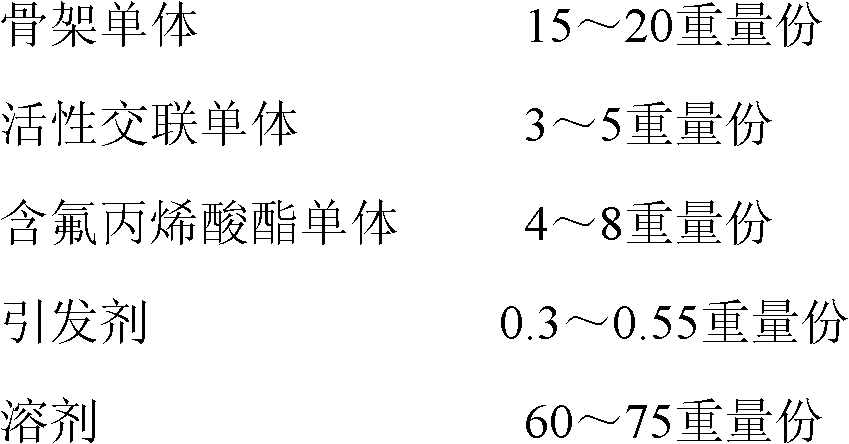

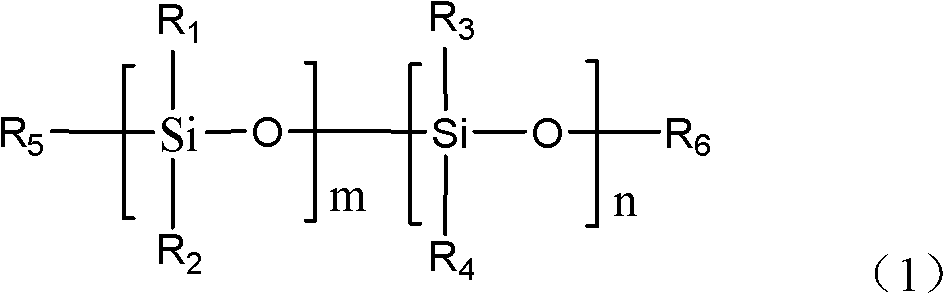

Method used

Image

Examples

Embodiment 1

[0032] 1. Add 50g of toluene into a four-neck flask, blow in nitrogen gas, and raise the temperature to 80°C. Subsequently, 4 g methyl methacrylate, 8 g butyl methacrylate, 2.81 g butyl acrylate, 3 g glycidyl methacrylate, 4 g dodecafluoroheptyl methacrylate, 0.21 g azobisiso For the mixed solution of butyronitrile, after constant temperature reaction for 0.5 h, continue to drop the mixed solution of 0.1 g of azobisisobutyronitrile and 10 g of toluene within 0.5 h. Continue to react for 2h. After the reaction, the resin was purified with n-hexane and dried in vacuum. The obtained fluorine-containing acrylic resin has a surface energy of 18 mN / m, a contact angle with water of 112° at room temperature, and a contact angle of 105° at -10°C.

[0033] 2. Add 150ml of toluene and 5g of silicon dioxide with a particle size of 20nm into a beaker, and use a 600W cell pulverizer to ultrasonically disperse for 3 minutes. Then 2g of γ-methacryloxypropyltrimethoxysilane was added dropwi...

Embodiment 2

[0037] 1. Add 50g of toluene into a four-neck flask, blow in nitrogen gas, and raise the temperature to 80°C. Subsequently, 4 g methyl methacrylate, 8 g butyl methacrylate, 2.81 g butyl acrylate, 3 g glycidyl methacrylate, 4 g trifluorooctyl methacrylate, 0.21 g azobisiso For the mixed solution of butyronitrile, after constant temperature reaction for 0.5 h, continue to drop the mixed solution of 0.1 g of azobisisobutyronitrile and 10 g of toluene within 0.5 h. Continue to react for 2h. After the reaction, the resin was purified with n-hexane and dried in vacuum. The surface energy of the obtained fluorine-containing acrylic resin was 16 mN / m, the contact angle of water at room temperature was 115°, and the contact angle at -10°C was 108.

[0038] 2. Add 150ml of toluene and 5g of silicon dioxide with a particle size of 50nm in a beaker, and use a cell pulverizer to ultrasonically disperse at 600W for 3min. Then 2g of hexadecyltrimethoxysilane was added dropwise, mixed even...

Embodiment 3

[0041] 1. Add 50g of toluene into a four-neck flask, blow in nitrogen gas, and raise the temperature to 80°C. Then add 5g methyl methacrylate, 6g butyl methacrylate, 4g butyl acrylate, 3g hydroxyethyl methacrylate, 4g trifluorooctyl methacrylate, 0.21g azobisisobutyl within 3h Nitrile mixed solution, after constant temperature reaction for 0.5h, add 0.1g azobisisobutyronitrile and 10g toluene mixed solution within 0.5h. After continuing the reaction for 2 h, the reaction was terminated, and the resin was purified with n-hexane and dried in vacuum. The surface energy of the obtained fluorine-containing acrylic resin was 17 mN / m, the contact angle of water at room temperature was 114°, and the contact angle at -10°C was 103°.

[0042] 2. Add 150ml of toluene and 5g of silicon dioxide with a particle size of 15-20nm in a beaker, and use a cell pulverizer to ultrasonically disperse at 600W for 3min. Then 2g of heptadecafluorodecyltriethoxysilane was added dropwise, mixed evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com