Method for immobilizing fructosyl transferase by taking mesoporous molecular sieve-chitosan as carrier

A technology of fructosyltransferase and mesoporous molecular sieve, which is applied in the field of food enzyme engineering, can solve the problems of easy leakage and poor stability of enzymes, and achieve the effects of low cost, good stability and many times of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

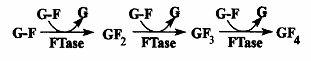

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh 30 mg of mesoporous molecular sieve SBA-15, add 18 mL of fructosyltransferase (total enzyme activity 400 U) diluted with 50 mM pH5. 15°C) shake for 2 hours, add 1 mL of 1.0% chitosan (pre-dissolved in 1.0% glacial acetic acid), then add 1 mL of 2.5% glutaraldehyde aqueous solution, shake in a constant temperature shaker for 4 hours, and centrifuge at 4000 rpm for 5 minutes , transfer the supernatant, wash the precipitate with 50mM pH5.0 citric acid-phosphate buffer to remove residual glutaraldehyde and unfixed enzyme protein, centrifuge again, and repeat the washing 3 times to obtain the immobilized fructosyl Transferase. The supernatant obtained by centrifugation was collected to determine the activity of immobilized enzyme 328U, the recovery rate was 82.0%, and the protein adsorption amount was 382mg protein / g SBA-15.

Embodiment 2

[0027] Accurately weigh 30 mg of mesoporous molecular sieve SBA-15, add 18 mL of fructosyltransferase (total enzyme activity 300 U) diluted with 50 mM pH7.0 citric acid-phosphate buffer, place in a constant temperature shaker (150 rpm) and shake for 2 h, Add 1mL of 2.0% chitosan (dissolved in 1.0% glacial acetic acid in advance), then add 1mL of 1.5% glutaraldehyde aqueous solution, shake in a constant temperature oscillator for 4h, centrifuge at 4000rpm for 5min, and transfer the supernatant , washed the precipitate with 50mM citric acid-phosphate buffer solution of pH 7.0 to remove residual glutaraldehyde and unimmobilized enzyme protein, centrifuged again, and repeated washing 3 times to obtain immobilized fructosyltransferase. The supernatant obtained by centrifugation was collected to determine the enzyme activity of 235 U of the immobilized enzyme, the recovery rate of enzyme activity was 78.3%, and the protein adsorption amount was 356 mg protein / g SBA-15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com