Quality detection methods of pearl powder and application thereof

A quality inspection method, pearl powder technology, applied in measuring devices, material analysis using radiation diffraction, instruments, etc., can solve the problems affecting consumer health and safety, low cost of pearl layer powder, elemental composition analysis and optical microscopy cannot be effective issues such as testing and evaluating the quality of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

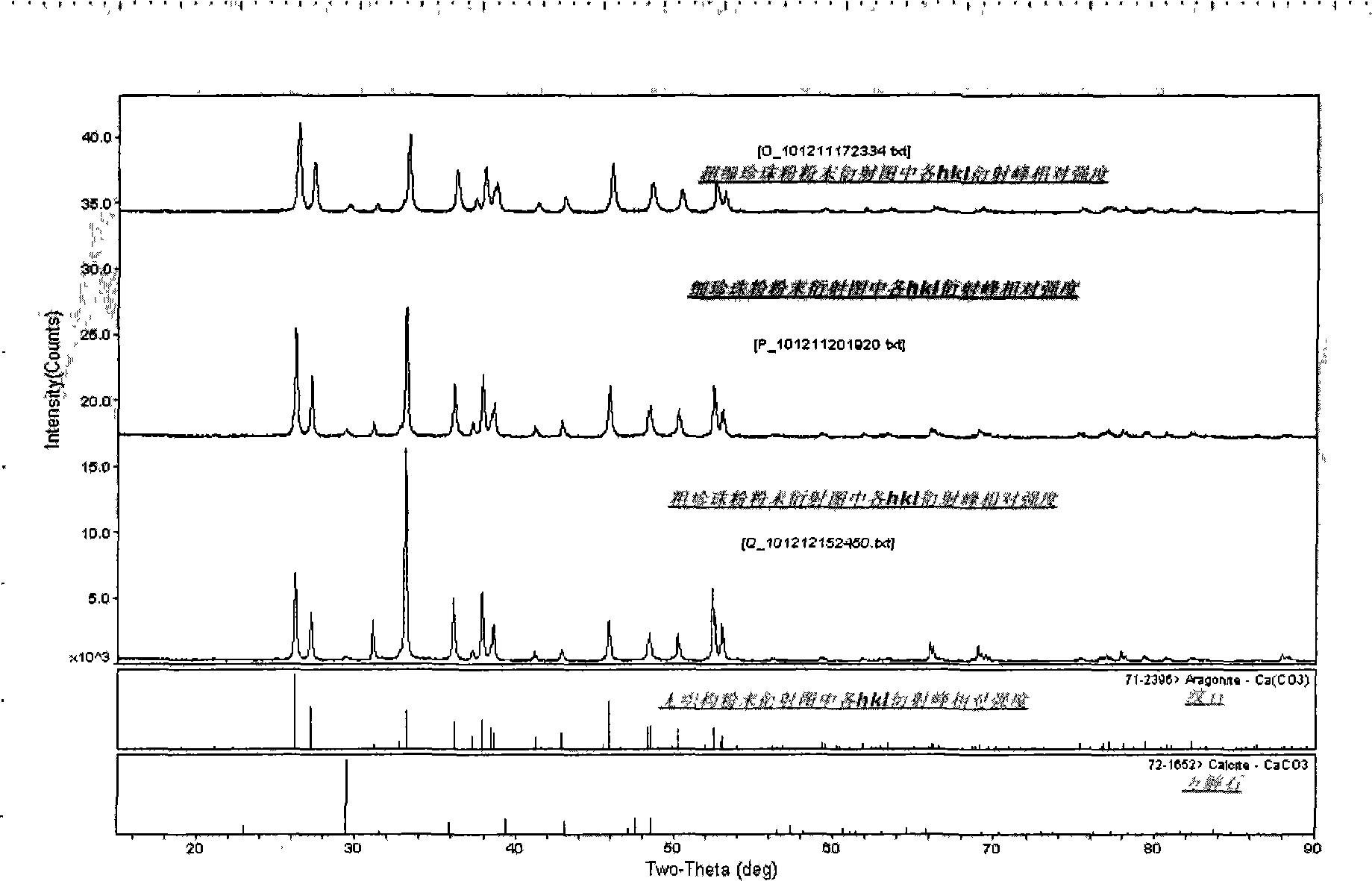

[0100] Example 1Detecting the Quality of Pearl Powder, Mother-of-Pearl Powder and Mixed Powder by XRD Diffraction Method

[0101] The test samples are obtained by purchasing various grades of pearl powder, or using cultured pearls and their parent mussel shells from Zhuji, Zhejiang Province, and preparing them according to the preparation method described in the present invention.

[0102] The samples were analyzed by XRD diffraction method, and the indicators for identifying and testing the quality of pearl powder were determined through comparative research.

[0103] 1. XRD analysis method and test conditions

[0104] (1) Instrument: XRD powder diffractometer, B-B diffraction geometry THET-THET goniometer, resolution of goniometer, half maximum width (FHWM) measured by non-instrumental intrinsic broadening standard sample (SRM1976 or srmLaB6) around 2θ28° )<0.07°2θ.

[0105] (2) Test conditions

[0106] CuKarf radiation, DS / SS: 1°RS 0.2mm, diffraction beam graphite mono...

Embodiment 2

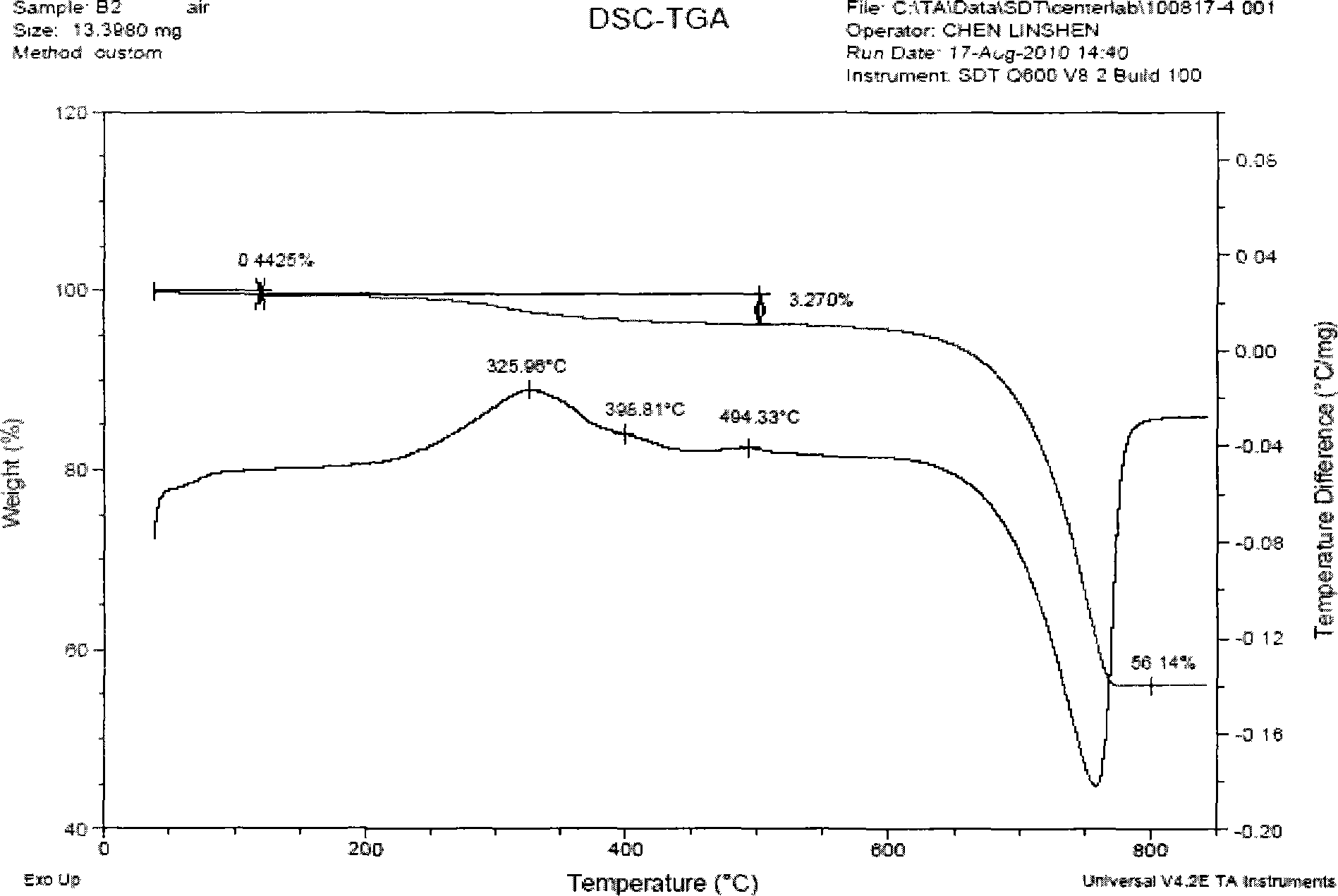

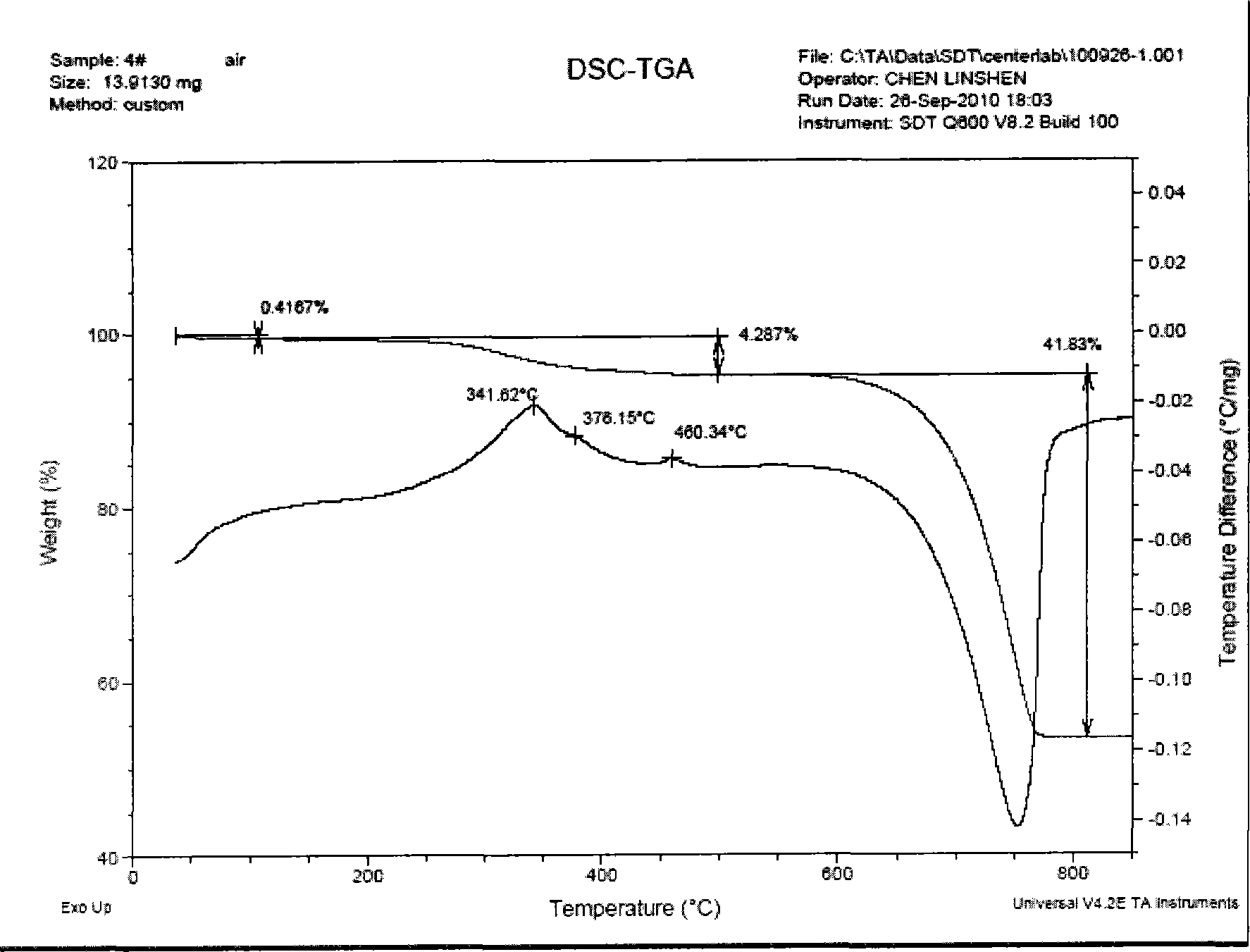

[0111] Example 2 Testing the quality of pearl powder, mother-of-pearl powder and mixed powder by thermal analysis

[0112] 1. Thermogravimetry and test conditions

[0113] a) Turn on the thermogravimetric analyzer (DSC / TGA) for 30 minutes and turn on the air;

[0114] b) Return to zero after the balance reading is stable, open the furnace to remove the sample, and use α-Al 2 o 3 Fill the crucible with 10-15 mg of the sample to be tested and put it back, and turn off the furnace;

[0115] c) After the balance reading is stable, raise the temperature from room temperature to 800°C at a rate of 10°C / min, measure the TG / DTA curve, save the data file, and use the instrument software to process the test data. The results are shown in Table 1.

[0116] It can be seen from Table 1 that, through DSC / TG analysis, compared with mother-of-pearl powder and mixed powder, the organic matter content in pearl powder is 3.5-5.0%, which is relatively high. Among them, the organic matter con...

Embodiment 3

[0117] Example 3 Identifying the quality of pearl powder, mother-of-pearl powder and mixed powder by thermal phase transition analysis of samples in XRD diffraction method

[0118] The analysis conditions for the thermal phase transition of the sample in the XRD diffraction method are: after the sample is placed in the diffractometer, it is raised to 400°C ± 5°C at a rate of 100°C / min, kept for 10 minutes, and then lowered to room temperature at a rate of 100°C / min , the diffraction data of samples were collected in the range of 15°C-70°C 2θ, and the results are shown in Table 1.

[0119] The quality detection result of table 1 pearl powder, mother-of-pearl powder, mixed powder

[0120]

[0121]

[0122] It can be seen from Table 1 that after the pearl powder is heated to 400°C±5°C, it is analyzed by XRD diffraction. The test results are significantly different from those of mother-of-pearl powder and mixed powder. %-15.0%; the percentage of aragonite to calcite in cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com