Method for measuring content of benzene and benzene series in hot melt glue

A technology of benzene series and hot melt adhesive, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems such as the lack of national standards or industry standards, the adverse effect of cigarette smell, the effect of cigarette smoking food quality, etc. Optimized, high recovery, effect of eliminating influences and disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

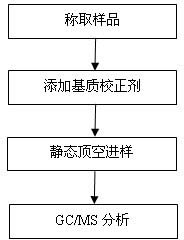

[0032] Determination of the content of benzene and benzene series in hot melt adhesives (the determination process is as follows figure 1 shown)

[0033] 1. Matrix correction agent: glycerol triacetate is used as the matrix correction agent.

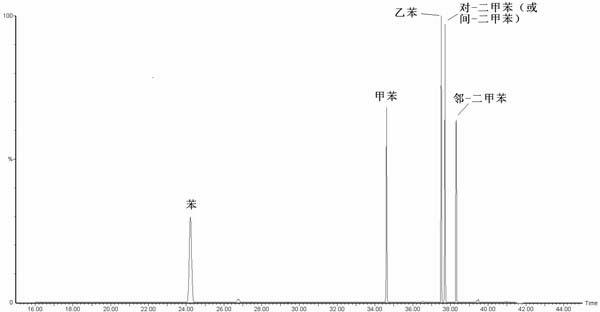

[0034] 2. Preparation of standard working solution

[0035] (1) Preparation of mixed standard stock solution Ⅰ: Accurately weigh 125mg of benzene, toluene, ethylbenzene, o-xylene and p-xylene (or m-xylene) in a 25mL volumetric flask, and use glycerol triacetate (Chromatographically pure solvent, purity ≥99%) Dilute to the mark, mix well to obtain mixed standard stock solution I, in which the concentration of each component is 5mg / mL;

[0036] (2) Preparation of mixed standard stock solution II: gradually dilute the mixed standard stock solution I with triacetin solution to obtain mixed standard solution II with a concentration of 0.8-1.2 mg / L;

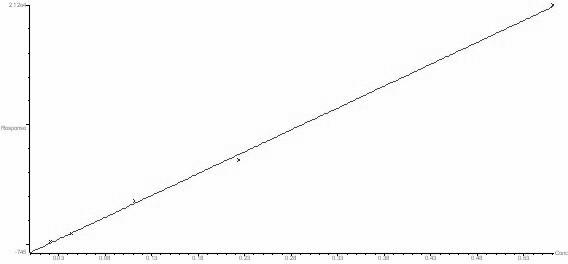

[0037] (3) Preparation of standard working solution: Accurately pipette 200 μL, 400 μL...

Embodiment 2

[0056] The present embodiment detects the repeatability and standard addition recovery of the inventive method:

[0057] Add 3 different concentrations of standard working solutions to the samples (the concentrations of the corresponding components in the standard solutions are (0.02mg / L, 0.04mg / L, 0.1mg / L), measure each sample 5 times, and the top The condition of empty chromatographic mass spectrometry analysis is the same as the headspace chromatographic mass spectrometry analysis condition of embodiment 1, calculates the relative standard deviation of the standard addition recovery of benzene and benzene series in the hot melt adhesive of this method and the measured value after the standard addition according to the analysis result, the result As shown in Table 4:

[0058] Table 4 The results of the recovery rate and standard deviation of the standard addition

[0059] Compound name Recovery rate(%) RSD (%) benzene 95.4 3.5 toluene 97.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com