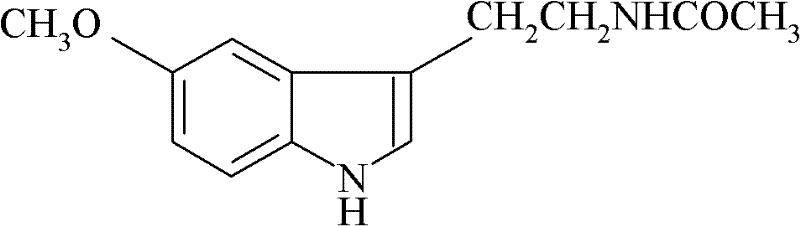

Preparation method of N-acetyl-5-methoxytryptamine

A technology of methoxytryptamine and acetic anhydride is applied in the preparation field of synthesizing N-acetyl-5-methoxytryptamine, can solve the problems of slow reaction speed, complicated operation, low yield and the like, and achieves less side reactions, The effect of low dosage and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

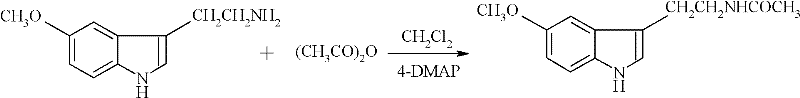

Embodiment 1

[0025] Add 38.05g (0.2mol) of 5-methoxytryptamine and 200ml of dichloromethane to a reactor equipped with a low-temperature and constant-temperature reaction bath, stirring, and a thermometer respectively. Under stirring, keep the reaction temperature at 5-10°C and drop in 0.5 hours A mixed solution containing 20.4g (0.2mol) of acetic anhydride and dichloromethane solvent (prepared according to the volume ratio of acetic anhydride:dichloromethane=1:2), was added, and 1.2g of 4-DMAP was added, and the reaction was carried out at room temperature for 2 hours.

[0026] Add 200ml of 1mol / L NaOH solution to the reaction solution for neutralization, wash with water to neutrality, add 1.0g of activated carbon to the separated organic phase for decolorization, distill out the dichloromethane solvent under reduced pressure (recycled after recovery), concentrate White crystals precipitated from the solution below 4°C, and after filtration and drying, 43.6 g of the target product N-acetyl...

Embodiment 2

[0028] Add 38.05g (0.2mol) of 5-methoxytryptamine and 300ml of dichloromethane to a reactor equipped with a low-temperature and constant-temperature reaction bath, stirring, and a thermometer respectively. Under stirring, keep the reaction temperature at 5-10°C and drop in 0.5 hours A mixed solution containing 21.44g (0.21mol) of acetic anhydride and dichloromethane solvent (prepared according to the volume ratio of acetic anhydride:dichloromethane=1:3) was added, 2.0g of 4-DMAP was added, and the reaction was carried out at room temperature for 2 hours.

[0029] Add 210ml of 1mol / L NaOH solution to the reaction solution for neutralization, wash with water to neutrality, add 1.8g of activated carbon to the separated organic phase for decolorization, distill out the dichloromethane solvent under reduced pressure (recycled after recovery), concentrated solution White crystals precipitated below 4°C. After filtration and drying, 44.4 g of the target product N-acetyl-5-methoxytrypt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com