Thermal treatment process for plunger of axial plunger pump

A technology of axial plunger pump and plunger, applied in heat treatment furnace, heat treatment equipment, metal material coating process, etc., can solve the problems of long processing time, limited range of material selection, high production cost, etc., and achieve low heat treatment cost, The effect of fast heat treatment and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The invention provides a plunger heat treatment process for an axial plunger pump. The steps are:

[0016] Step 1. Put the semi-finished plunger into a vacuum furnace, and heat it up to 920°C for 15 minutes;

[0017] Step 2, keep warm for 35 minutes;

[0018] Step 3. Cool down to 845°C and release the furnace. Fill the vacuum furnace with acetylene and nitrogen while heating, maintaining and cooling to realize the carbonitriding treatment of the surface layer of the plunger. Nitrogen is used for nitriding. For carburizing treatment, it is divided into 6 stages and each stage lasts for 3 minutes;

[0019] Step 4. After being released from the furnace, quenching treatment is performed, followed by tempering treatment. The tempering temperature is 130° C., and finally air-cooled to room temperature.

Embodiment 2

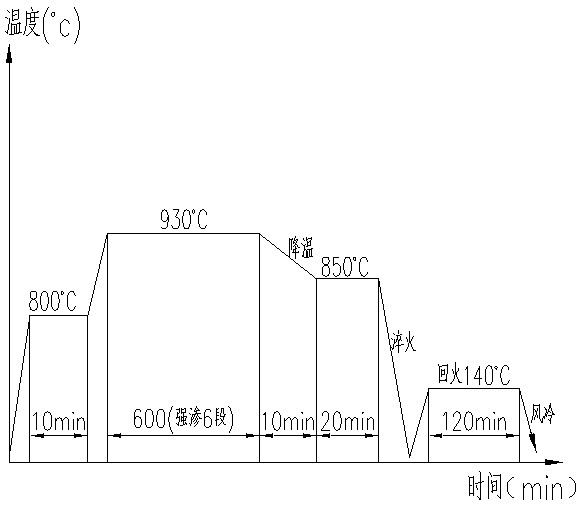

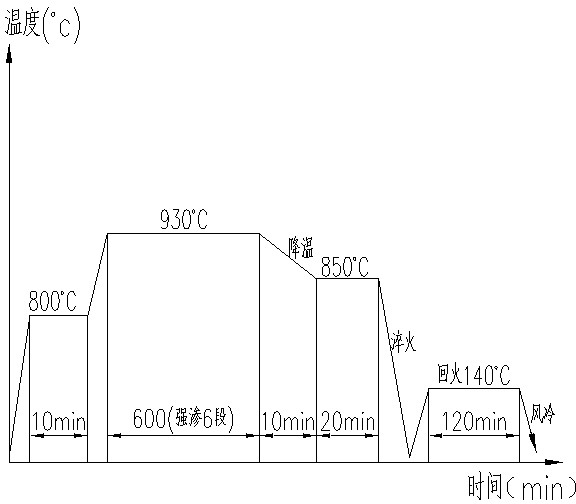

[0021] The invention provides a plunger heat treatment process for an axial plunger pump. The steps are:

[0022] Step 1. Put the semi-finished plunger into a vacuum furnace, and heat it up to 930°C for 20 minutes;

[0023] Step 2, keep warm for 30 minutes;

[0024] Step 3. Cool down to 850°C and release the furnace. Fill the vacuum furnace with acetylene and nitrogen while heating, maintaining and cooling to realize the carbonitriding treatment of the surface of the plunger. Nitrogen is continuously charged, and acetylene is charged in 6 stages. Enter, each segment lasts 3 minutes;

[0025] Step 4: Quenching treatment is performed after being released from the furnace, followed by tempering treatment. The tempering temperature is 140° C., and finally air-cooled to room temperature.

[0026] The process route of above-mentioned steps is as figure 1 shown.

Embodiment 3

[0028] The invention provides a plunger heat treatment process for an axial plunger pump. The steps are:

[0029] Step 1. Put the semi-finished plunger into a vacuum furnace, and heat it up to 940°C for 25 minutes;

[0030] Step 2, keep warm for 25 minutes;

[0031] Step 3, cooling down to 855°C, and filling the vacuum furnace with acetylene and nitrogen while heating, maintaining, and cooling, to realize the carbonitriding treatment of the surface layer of the plunger, nitrogen is continuously charged, and the acetylene is divided into 6 parts. segment charging, each segment lasts 3 minutes;

[0032] Step 4. After being released from the furnace, quenching treatment is performed, followed by tempering treatment. The tempering temperature is 150° C., and finally air-cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com