Method for preparing DLC (Diamond-Like Carbon) coating with high visible light transmissivity

A technology with high transmittance and visible light, applied in coating, metal material coating process, sputter plating, etc., can solve the problems of high transmittance of visible light, etc., achieve good transmittance, non-toxic tail gas, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

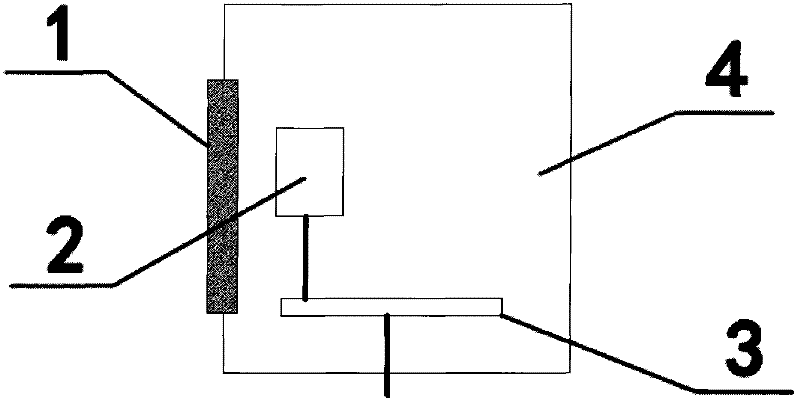

[0017] A preparation method of a visible light high transmittance DLC coating of the present embodiment, the coating is used to protect optical devices working in the visible light band, comprising the following steps:

[0018] Step 1: Evacuate the coating vacuum chamber to 5.0*10 -3 Vacuum degree above Pa;

[0019] Step 2: Use a heater to heat the coating vacuum chamber to 200-400° C., and keep it for at least 1 hour, and make the vacuum degree of the coating vacuum chamber reach 1.0×10 -3 Above Pa;

[0020] Step 3: Introduce argon gas into the coating vacuum chamber to make the vacuum degree in the vacuum chamber reach 1.0-20.0Pa,

[0021] Step 4: Turn on the ion beam power supply and start the ion cleaning process on the substrate surface; during the ion cleaning process, the bias voltage is 1000V, the working voltage applied to the ion beam is greater than 1000V, and the working current is between 50mA-150mA; the ion cleaning process The time is 5-30 minutes;

[0022] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com