High-power integrated LED (light-emitting diode) lamp body structure with micro lens array

A technology of microlens array and LED lamp body, which is applied to the parts of lighting devices, lighting devices, light sources, etc., can solve the problems such as difficult to overcome the yellow circle on the edge, and achieve the effects of saving mechanism space, easily increasing power, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

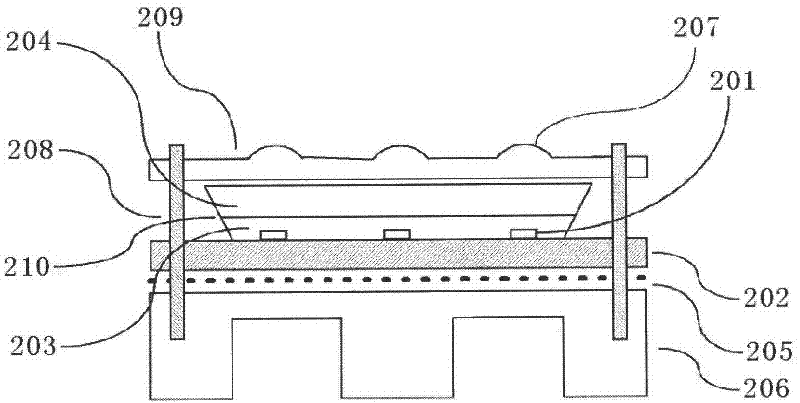

[0024] Please refer to figure 2 In this embodiment one, a micro-convex lens array is used, and the main structure is: at least two or more GaN-based blue-ray chips 201 are mounted on the aluminum substrate 202, and the blue-ray chips 1 are arranged in a certain way. arrangement. The upper part of the chip 201 is coated with YAG yellow fluorescent powder 203, and then potted with silica gel 204; the micro-convex lens array 209 is a collection of micro-convex lens units 207 that are integrated as a whole; the micro-convex lens array 209 is installed on a high-power integrated LED light source On the top of 210, the micro-convex lens array 209 has a positioning hole, and is connected with the base (aluminum substrate) 202 and the heat sink 206 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com