Method for determining initial boiling point and final boiling point of three-oil mixture in tar

A determination method and three-mixed oil technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of damage to the health of analysts, pollution in the distillation process, cumbersome operation process, etc., to achieve high accuracy, improve the working environment, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

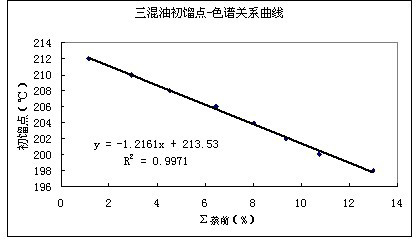

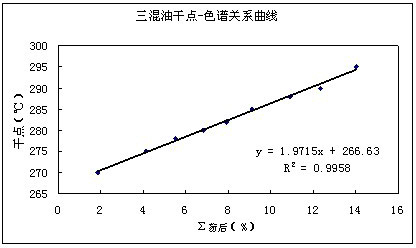

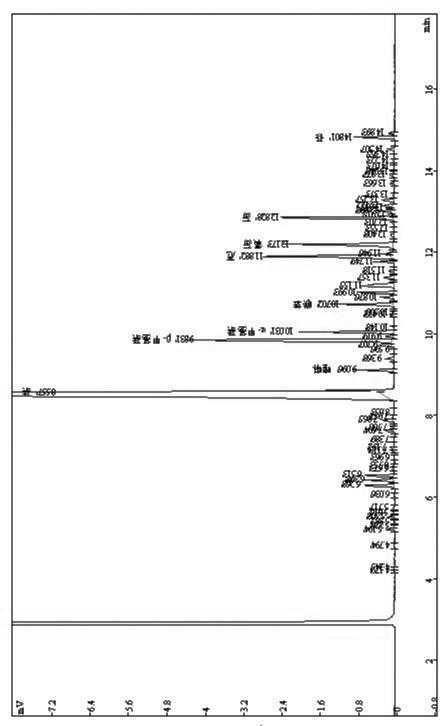

[0046] Example: Take 1mL of the three-mixed oil sample in a 12mL sample bottle, add 5mL of acetone to dissolve, take 0.4 μL of the sample after mixing and inject it into the chromatograph to obtain the corresponding chromatogram, use the above-mentioned first regression curve equation y=- 1.2161x+213.53 and the second regression curve equation y=1.9715x+266.63 analysis results; calculate Σ 萘前 =6.22, the corresponding initial boiling point is 206°C, calculate Σ 芴后 =8.15, the dry point is 283°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com