Preparation technology for titanium dioxide nano membrane in dye-sensitized solar cell

A technology for solar cells and dye sensitization, which is applied in the preparation process of double-layer TiO2 nano-membrane and the field of photoanode preparation of dye-sensitized solar cells, which can solve the problems of easy cracking, thin thickness and low porosity of photoanode , to achieve the effect of improving photoelectric conversion efficiency, appropriate thickness and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preparation process of titanium dioxide nano-film in a dye-sensitized solar cell, the key of which is: this process adopts P25 type TiO 2 Powder, and TiO with a particle size of 150-300nm 2 The powder is the base material of the slurry, and the nano-scale dense film and the loose porous film are sequentially prepared on the conductive substrate glass, and compounded to form the photoanode of the dye-sensitized solar cell. The specific steps include:

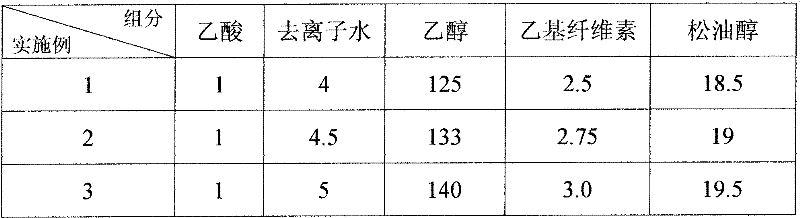

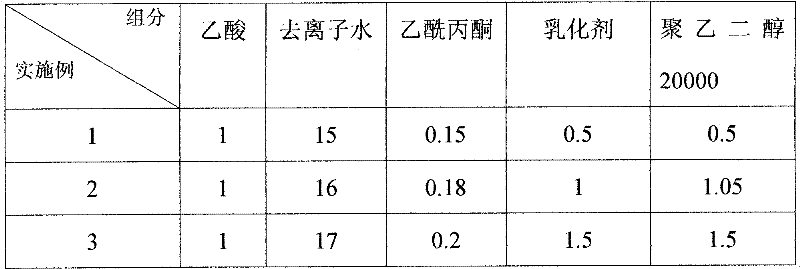

[0023] A. Preparation of dense film layer slurry: use P25 type TiO2 The powder is used as the base material, and the oil-based blending agent is added according to the mass ratio of 1: (24-32), and the particle size of TiO with a particle size of 200-300 meshes is obtained through classification grinding, magnetic stirring and ultrasonic vibration treatment. 2 Homogenize the slurry and evaporate the TiO with a rotary evaporator 2 Homogenize the volatile substances in the slurry to form the oily TiO required for the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com