Treatment method for lithium iron phosphate material

A technology of lithium iron phosphate and a treatment method, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve problems such as affecting migration and capacity attenuation, and achieve the effects of improving ion conductivity, improving high-temperature performance, and reducing iron dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

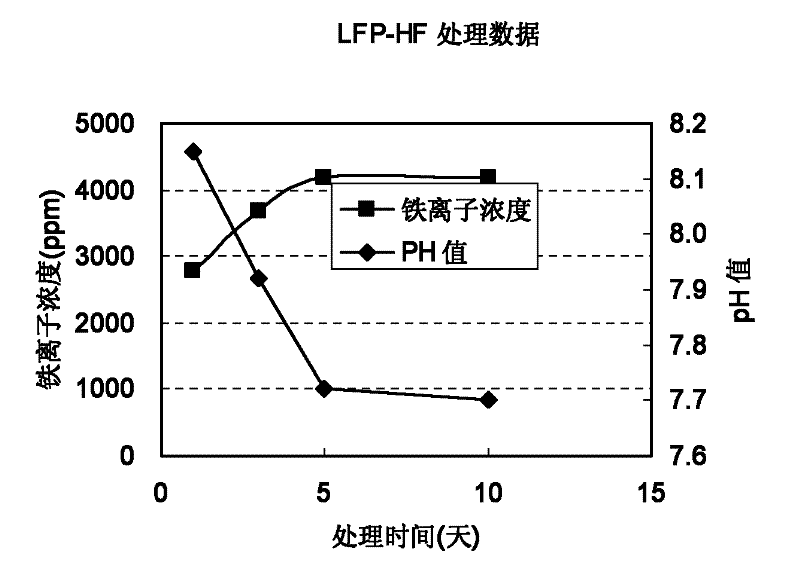

[0027] Prepare 150ml of 100ppm HF aqueous solution, add 50g of carbon-coated lithium iron phosphate powder, seal the container, mix evenly, transfer to a constant temperature oven at 60°C, and stir at constant temperature for 24 hours to obtain a black suspension. The solution was cooled to room temperature, suction filtered, and the pH value and dissolved Fe content of the filtrate were shown in the appendix figure 1 . The filtrate was washed repeatedly with deionized water, and after preliminary drying in an oven, it was transferred to a vacuum oven at a constant temperature of 130°C for vacuum drying for 24 hours. After grinding, the acid-treated lithium iron phosphate powder was obtained, and the water content of the powder was 2400ppm. Grinding after cooling to obtain HF-treated lithium iron phosphate material.

Embodiment 2

[0029] Prepare 150ml of 9000ppm hydrochloric acid aqueous solution, add 50g of lithium iron phosphate powder, seal the container, mix evenly, transfer to a constant temperature oven at 26°C, and stir at constant temperature for 15 hours to obtain a black suspension. Cool the black suspension to room temperature , suction filtration, and the pH value of the filtrate was 7.5. The filtrate was washed repeatedly with deionized water, and after preliminary drying in an oven, it was transferred to a vacuum oven at a constant temperature of 200°C for vacuum drying for 21 hours. After grinding, the acid-treated lithium iron phosphate powder was obtained, and the water content of the powder was 5000ppm. Grinding after cooling to obtain the lithium iron phosphate material treated with hydrochloric acid.

Embodiment 3

[0031] Prepare 150ml of 50ppm nitric acid aqueous solution, add 50g of lithium iron phosphate powder, seal the container, mix evenly, transfer to a constant temperature oven at 100°C, and stir at constant temperature for 32 hours to obtain a black suspension. Cool the black suspension to room temperature , suction filtration, and the pH value of the filtrate was 7.7. The filtrate was washed repeatedly with deionized water, and after preliminary drying in an oven, it was transferred to a vacuum oven at a constant temperature of 80°C for vacuum drying for 25 hours. After grinding, the nitric acid-treated lithium iron phosphate powder was obtained, and the water content of the powder was 3000ppm. Grinding after cooling to obtain the lithium iron phosphate material treated with nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com