Die-casting argon-blowing protection device

A protection device and mold casting technology, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as unfavorable mold casting product molding, unstable argon gas flow, and difficult forming process of iron sheet rings, etc., to achieve convenient Remote operation, convenient production, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Attached below Figure 1-3 One is to describe the preferred embodiments of the present invention in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] In the embodiment of the present invention:

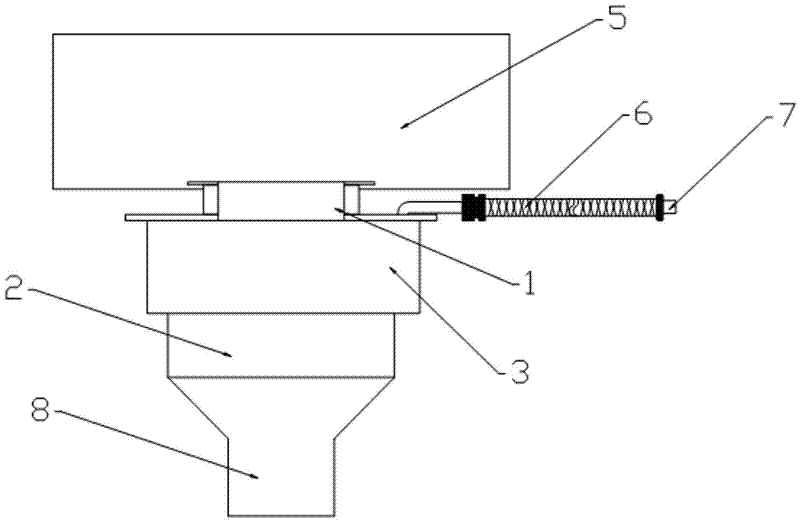

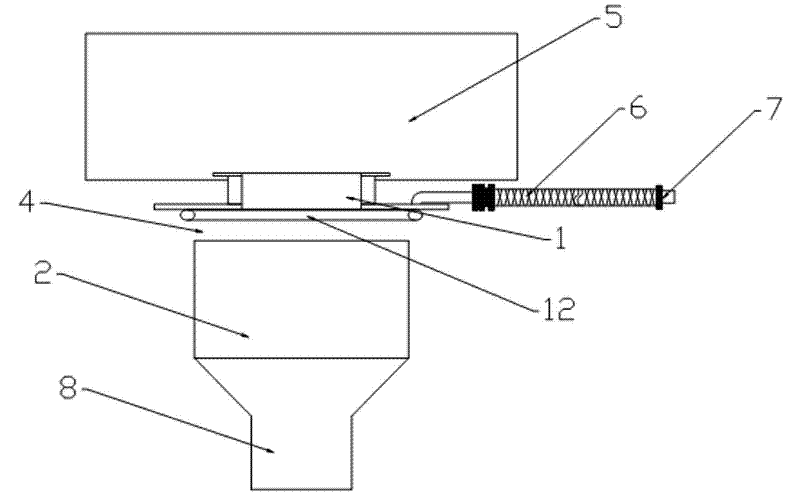

[0020] as attached figure 1 and 2 As shown, a molded argon blowing protection device includes an argon blowing protection piece 1 , an argon sealing brick 2 and an annular ceramic fiber cloth windshield 3 .

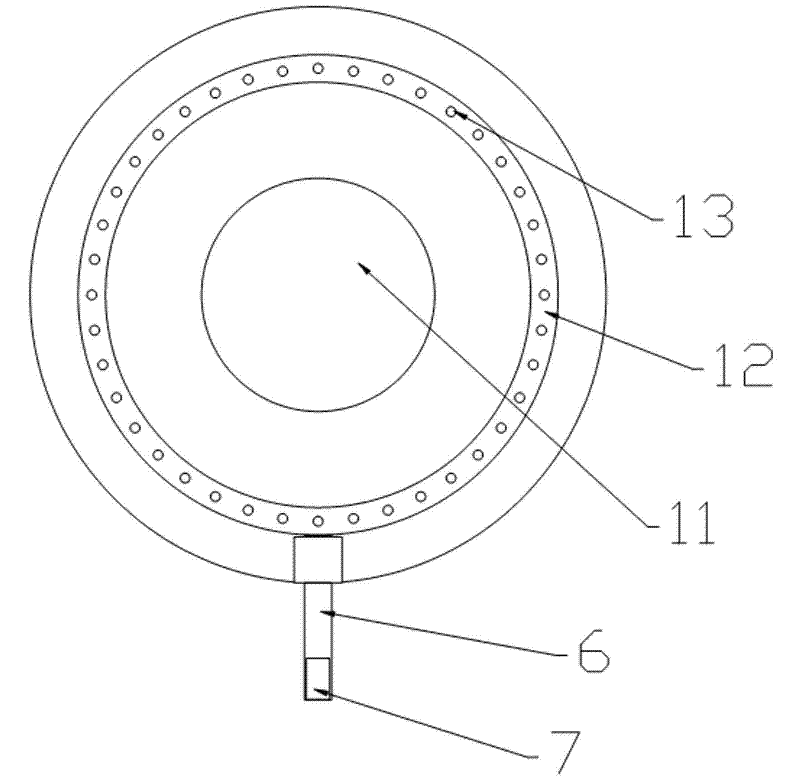

[0021] as attached image 3 As shown, the upper part of the argon blowing protection part 1 is clamped with the ladle 5, and the argon blowing protection part 1 is fixed on the ladle 5 through the clamping part during use. The argon blowing protector 1 is provided with an inner hole 11 , and molten steel flows from the ladle 5 through the inner hole 11 to the argon sealing brick 2 during use. A pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com