Granular stearate, and preparation method and application thereof

A stearate and granular technology, applied in the field of granular stearate and its preparation, can solve the problems of small particle size of stearate, affecting the performance of main plastic products, difficulty in hygroscopicity and the like, and achieve hygroscopicity. Small, overcome the difficulty of feeding and metering, avoid dust pollution or the effect of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

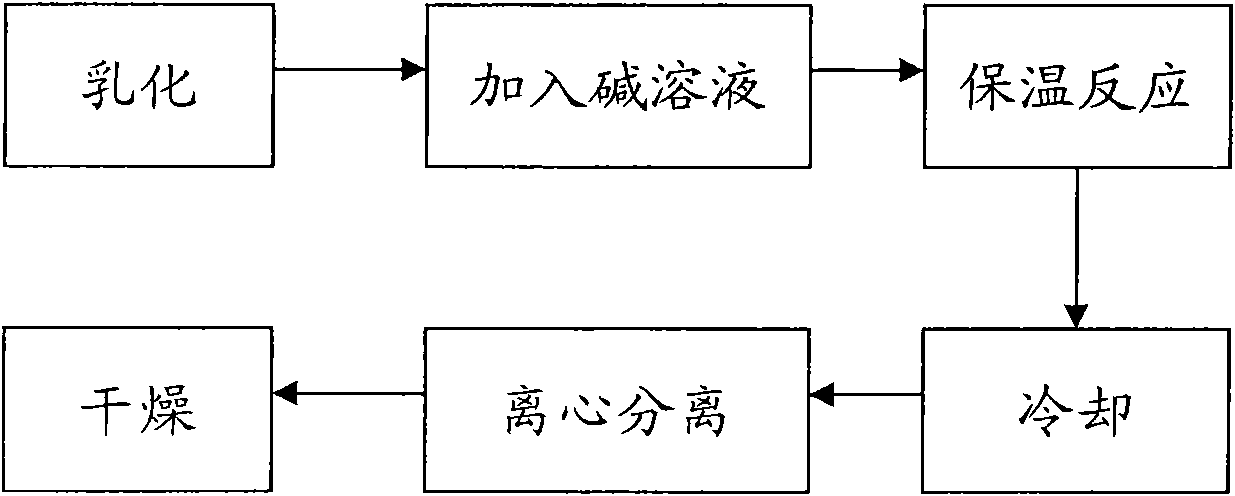

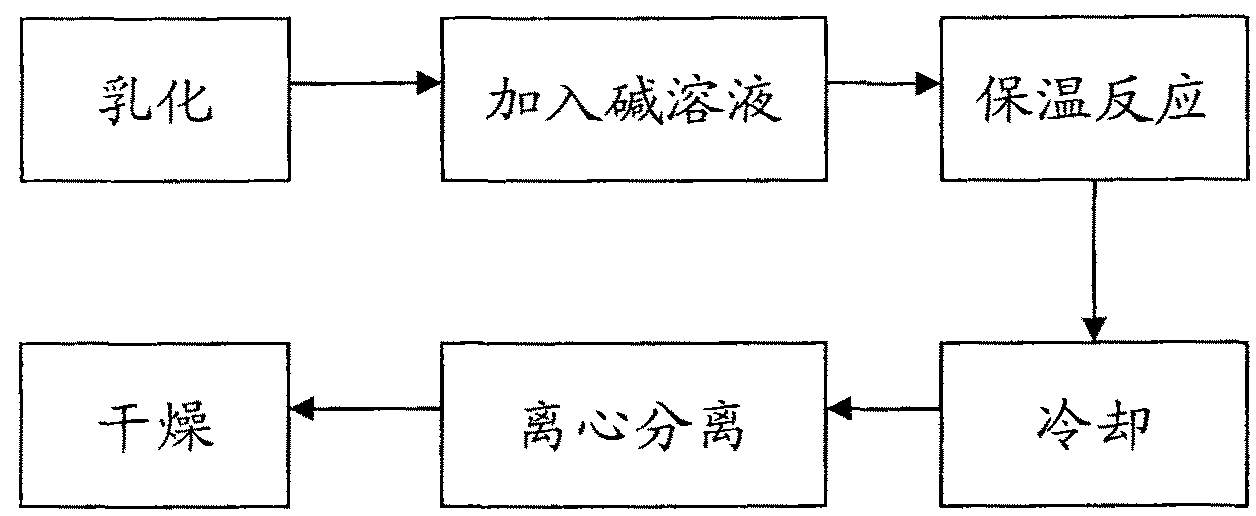

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the synthesis of calcium stearate

[0040] Add 900mL of water into a 3L closed reactor; add 300g of stearic acid; add 62 g of calcium chloride (on a dry basis); and add 22.5 g of sodium dodecylbenzenesulfonate under stirring conditions. Heat the temperature of the reactor to 125±5°C to fully emulsify the stearic acid in the aqueous solution of calcium chloride. Add the alkali lye prepared with 48g sodium hydroxide then, after adding, make reaction mixture insulation reaction 2 hours. After the reaction is completed, cool, centrifuge and dry to obtain a particle size of 180-830 μm and a bulk density of 0.48 g / cm 3 and granular calcium stearate with a heat loss of 1.0%.

Embodiment 2

[0041] Embodiment 2: the synthesis of calcium stearate

[0042] Add 900mL water in 3L airtight reactor; Add 300g stearic acid; Add 62 calcium chloride (on a dry basis); Fully emulsified in aqueous solution of calcium chloride. Add the alkali lye prepared with 48g sodium hydroxide then, after adding, make reaction mixture insulation reaction 2 hours. After the reaction is completed, cool, centrifuge and dry to obtain a particle size of 600-880 μm and a bulk density of 0.50 g / cm 3 And heat loss 1.0% by weight of granular calcium stearate.

Embodiment 3

[0043] Embodiment 3: the synthesis of calcium stearate

[0044] Add 900mL of water into a 3L closed reactor; add 300g of stearic acid; add 62 g of calcium chloride (on a dry basis); and add 22.5 g of sodium dodecylbenzenesulfonate under stirring conditions. Heat the temperature of the reactor to 110±5°C to fully emulsify the stearic acid in the aqueous solution of calcium chloride. Add the alkali lye prepared with 48g sodium hydroxide then, after adding, make reaction mixture insulation reaction 2 hours. After the reaction is completed, cool, centrifuge and dry to obtain a particle size of 150-180 μm and a bulk density of 0.32 g / cm 3 And heat loss 1.5% by weight of granular calcium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com