Solvent refining method for pyromellitic dianhydride

A pyromellitic dianhydride and solvent refining technology, which is applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of difficult pollution control and high energy consumption of high-end PMDA, and achieve short process flow, The effect of using less equipment and high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

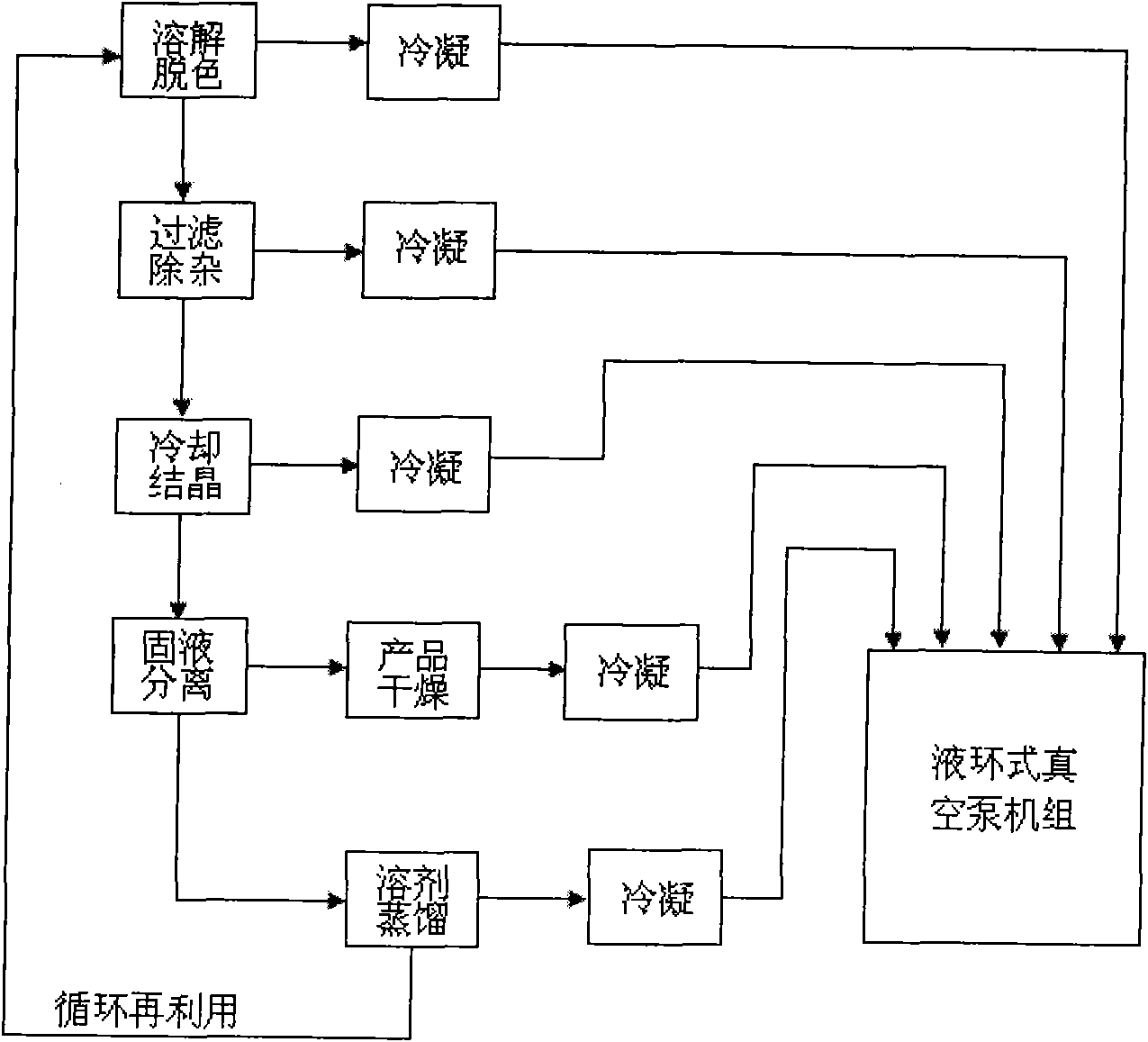

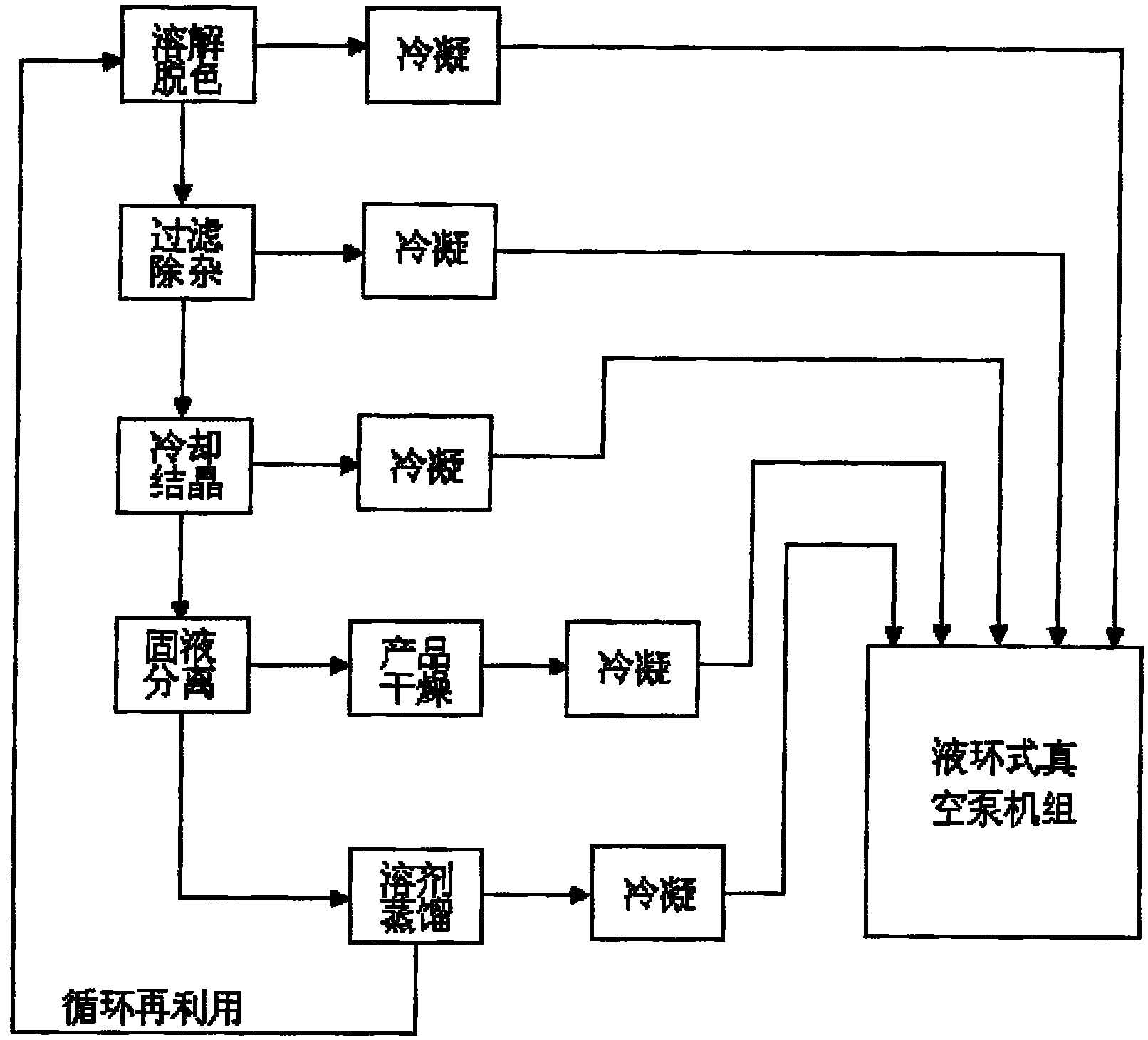

[0023] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0024] Such as figure 1 As shown, the present invention discloses a solvent refining method of pyromellitic dianhydride, which is realized through six steps of dissolving and decolorizing, filtering to remove impurities, cooling crystallization, solid-liquid separation, drying and solvent distillation. The filtration and impurity removal, cooling crystallization, solid-liquid separation, drying, solvent distillation and material transportation are all realized by the negative pressure generated by the liquid ring vacuum pump unit.

[0025] In the present invention, the dissolving and decolorizing steps are to dissolve the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com