Method and device for one-stage pressure swing adsorption hydrogen extraction and carbon-rich gas recovery

A pressure swing adsorption, hydrogen technology, applied in separation methods, chemical instruments and methods, hydrogen separation, etc., can solve the problems of low carbon monoxide and carbon dioxide recovery rate, low hydrogen recovery rate, large equipment investment, etc., and achieve stable and reliable process indicators. , The effect of saving investment and reasonable device layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

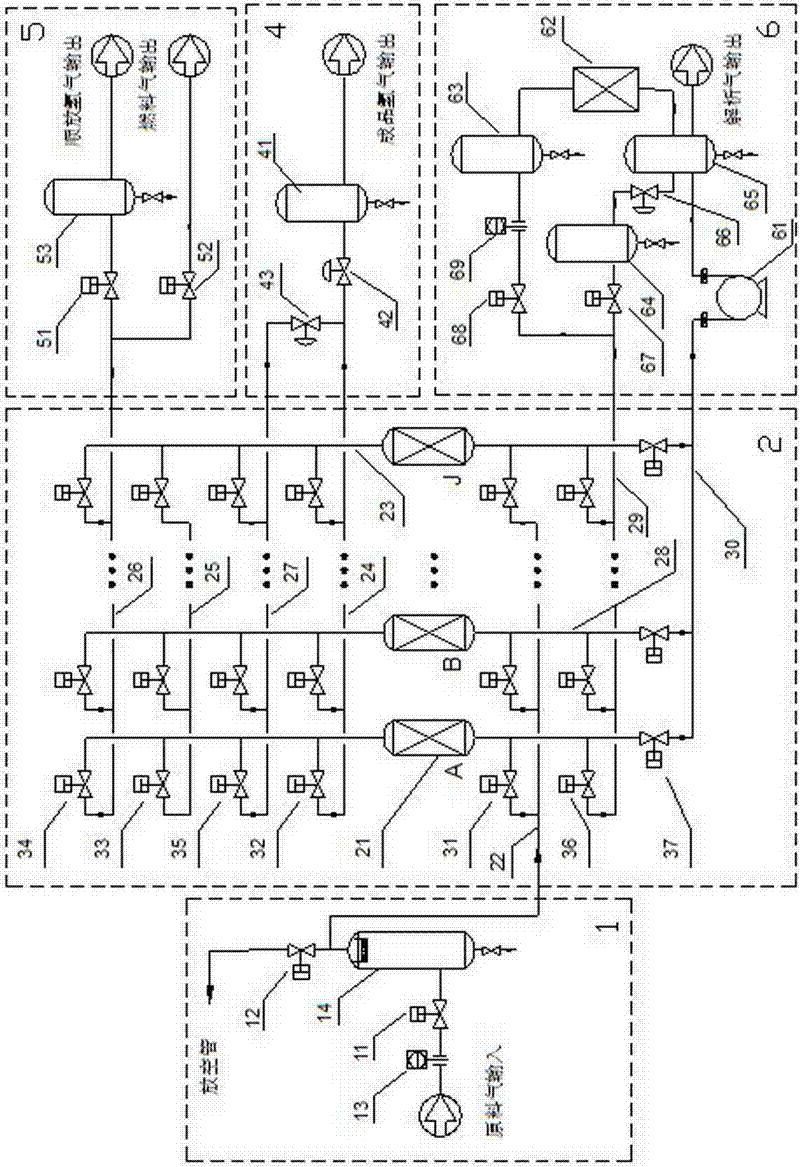

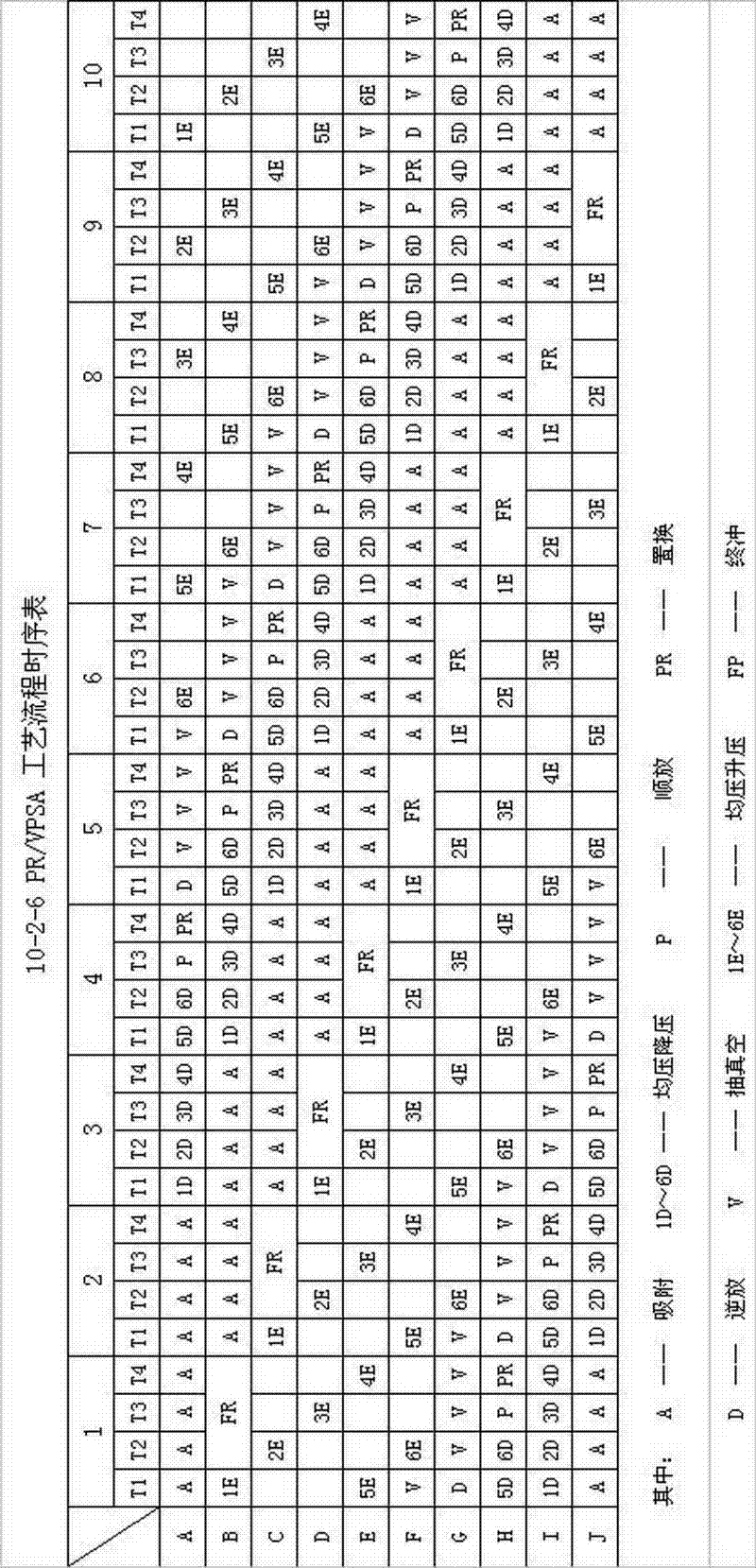

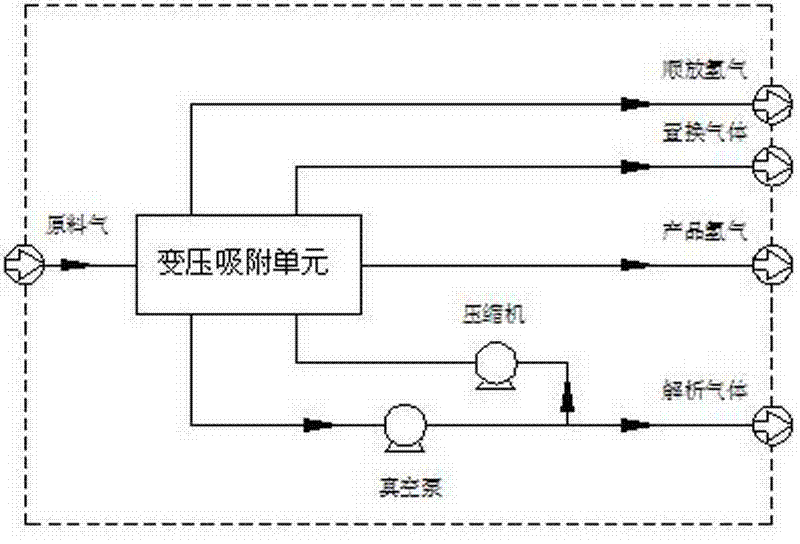

[0041] Embodiment: The one-stage pressure swing adsorption hydrogen extraction and recovery carbon-rich gas device of this embodiment, such as figure 1 As shown, the high-purity hydrogen is extracted from methanol synthesis purge gas by using the principle of pressure swing adsorption as the product gas, and the high-purity carbon-rich gas generated during the desorption process is recovered as the raw material gas of the methanol plant, and the relatively high concentration The hydrogen released in parallel is returned to the methanol system, and the low-concentration hydrogen is discharged into the fuel pipe network as fuel gas. The pressure swing adsorption hydrogen extraction unit adopts 10-2-6PR / VPSA, such as figure 2 As shown, the number of adsorption towers is 10, of which there are always two adsorption towers in the adsorption state, and the pressure equalization process is 6 times. Each cycle in the process flow includes the adsorption process, the pressure equalizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com