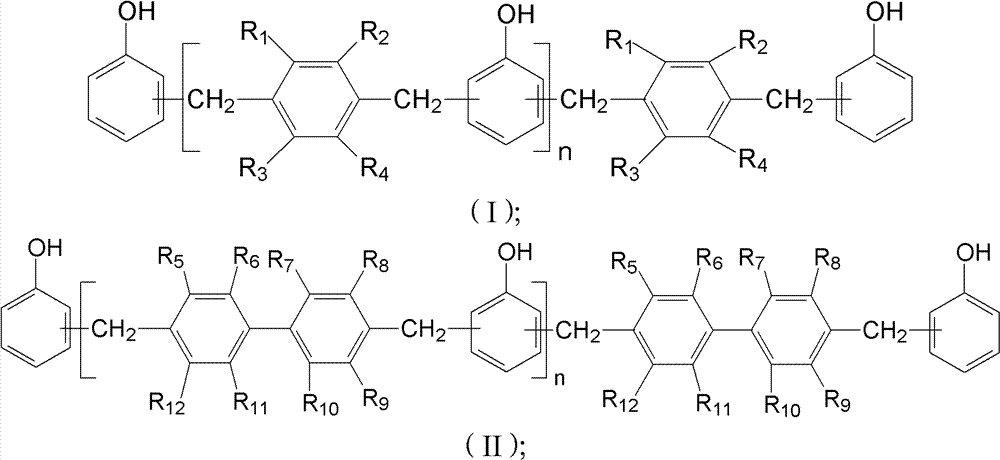

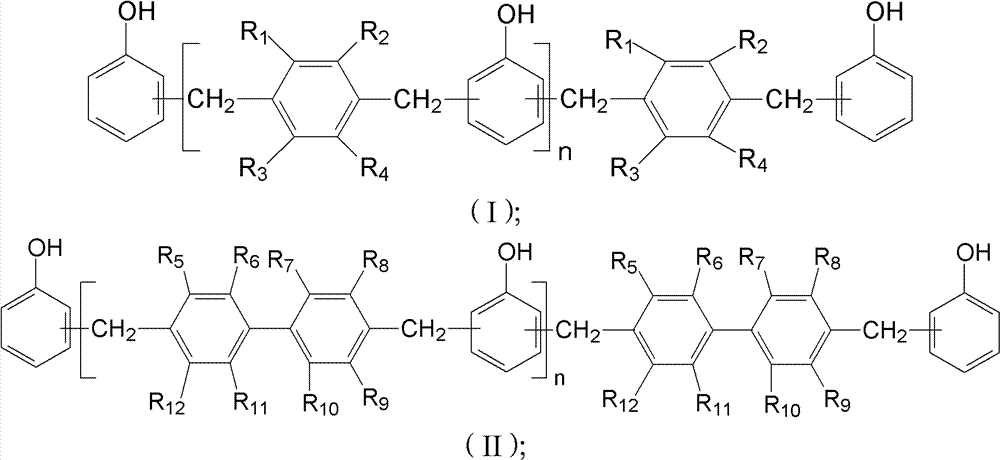

Light-color phenol aralkyl resin and preparation method thereof

A technology of phenol aralkyl and aralkyl, which is applied in the field of light-colored phenol aralkyl resin and its preparation, and can solve problems such as limiting the application of phenol aralkyl resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of light color phenol aralkyl resin, comprises the following steps:

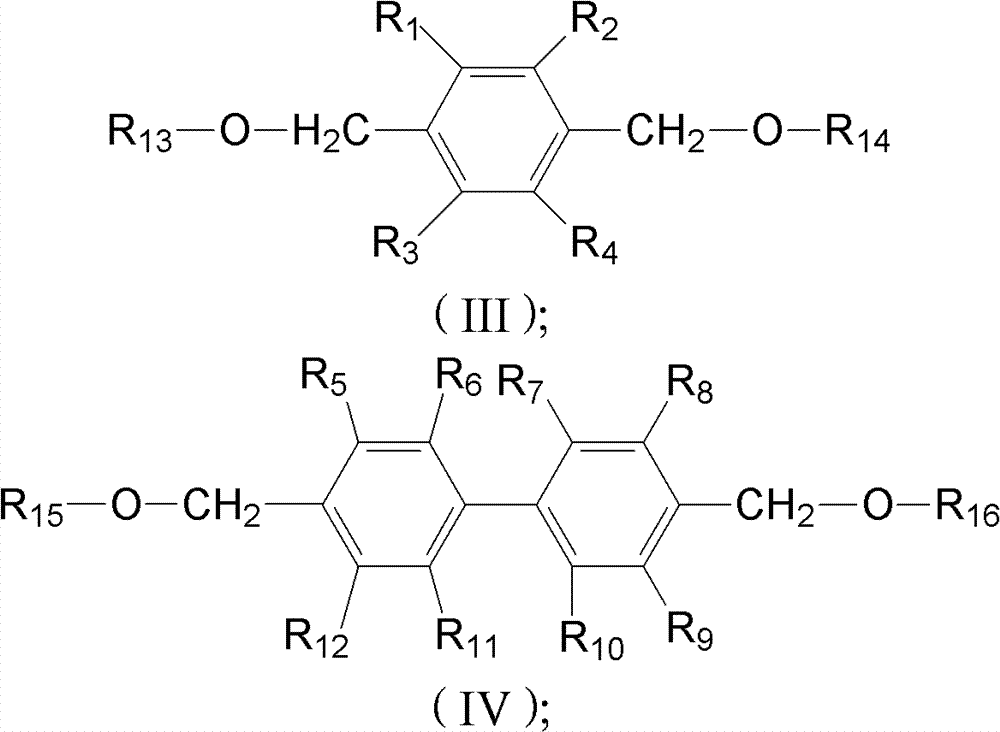

[0037] A Friedel-Crafts reaction occurs between phenol and an aralkyl compound under the action of an acidic catalyst to obtain an intermediate product, and the aralkyl compound has a structure of formula (III) or formula (IV):

[0038]

[0039] R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , R 9 , R 10 , R 11 , R 12 , R 13 , R 14 , R 15 and R 16 are independently hydrogen, methyl or ethyl;

[0040] A reducing agent is added to the intermediate product, and a light-colored phenol aralkyl resin is obtained after an oxidation-reduction reaction occurs.

[0041]The present invention uses phenol and aralkyl compounds as raw materials, and Friedel-Crafts Reaction (Freidel-Crafts Reaction) occurs under the action of an acidic catalyst to generate intermediate products. Since the Friedel-Crafts reaction needs to be carried ou...

Embodiment 1

[0056] Mix 100g of phenol, 100g of p-xylylene dimethyl ether and 3g of dilute sulfuric acid with a mass concentration of 20%, replace with nitrogen 3 times, raise the temperature to 120°C for 3 hours under the protection of nitrogen, and then add 1.1g of 48% Neutralize the sodium hydroxide solution, then add 0.2g sodium borohydride, react at 80°C for 40 minutes, wash the obtained product with water, and distill under reduced pressure until the free phenol content is ≤0.1%, to obtain a colorless, transparent phenol aralkyl resin.

[0057] The Gardner color, softening point and free phenol content of the phenol aralkyl resin were measured, and the results are shown in Table 1. Table 1 shows the performance parameters of the phenol aralkyl resin provided by the examples and comparative examples of the present invention.

Embodiment 2

[0065] Mix 100g of phenol, 100g of biphenyl dimethyl dimethyl ether and 2g of p-toluenesulfonic acid with a mass concentration of 20%, replace with nitrogen three times, raise the temperature to 140°C for 4 hours under the protection of nitrogen, and then add 0.2g of Neutralize with 48% sodium hydroxide solution, then add 1.3g sodium dithionite, react at 60°C for 70 minutes, wash the obtained product with water, and distill under reduced pressure until the free phenol content is ≤0.1%, to obtain colorless, transparent phenol Aralkyl resins.

[0066] The Gardner color, softening point and free phenol content of the phenol aralkyl resin were measured, and the results are shown in Table 1. Table 1 shows the performance parameters of the phenol aralkyl resin provided by the examples and comparative examples of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com