One-way traveling wave annular cavity single-frequency quasi-three-level solid laser

A solid-state laser, quasi-three-level technology, applied in the laser field, can solve problems such as unfavorable single-frequency laser stable operation, increase system cost and complexity, and influence on laser output performance, so as to reduce adverse effects, reduce cost and complexity , the effect of high degree of linear polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

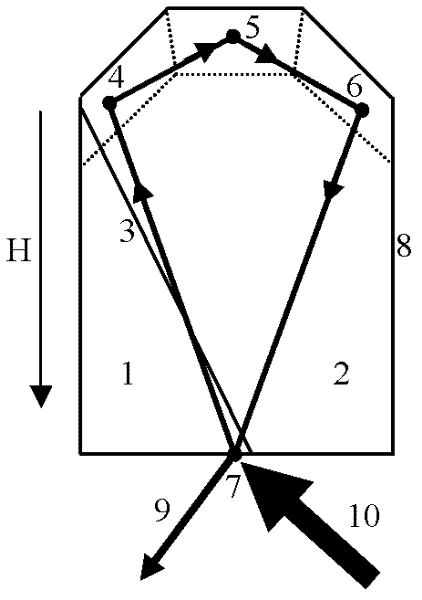

[0015] exist figure 1 In the illustrated embodiment, the ring laser resonator is formed directly from a thermally bonded laser crystal 8 . Applied magnetic field H along figure 1 The direction shown is applied to the thermally bonded laser crystal 8, and the semiconductor laser pumping source 10 is used along the figure 1 The thermally bonded laser crystal 8 is pumped through the end face of the reflection point 7 in the direction shown, and a single-frequency laser output 9 can be obtained at the reflection point 7 .

[0016] like figure 1 As shown, the thermally bonded laser crystal 8 is formed by thermal bonding at the interface 3 between an optically isotropic crystal 1 doped with active ions and an optically isotropic crystal 2 not doped with active ions, The crystal 1 doped with active ions is the same as the host crystal of the crystal 2 not doped with active ions, and the host crystal has Faraday magneto-optical properties (for example, a YAG crystal as a host cryst...

Embodiment 2

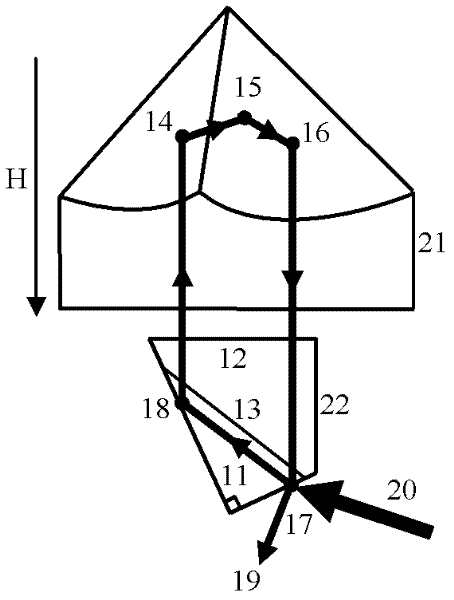

[0023] exist figure 2 In the illustrated embodiment, the ring resonator is composed of two optical elements, a corner cube prism 21 and a thermally bonded laser crystal 22 . The corner cube is an optical element with the characteristic that the direction of the outgoing beam is parallel to the direction of the incident beam, and the corner cube is made of an optical medium (for example, fused silica glass) with Faraday magneto-optical properties. Applied magnetic field H along figure 2 The directions shown apply to the corner cube 21 . Applying an external magnetic field to the corner cube prism 21 not only provides greater freedom in selecting magneto-optical materials, but also facilitates the fixed installation of the magnet, for example, the corner cube prism 21 can be directly placed in the inner ring of the ring magnet . Using semiconductor laser pumping source 20 along figure 2 The thermally bonded laser crystal 22 is pumped through the end face of the reflection...

Embodiment 3

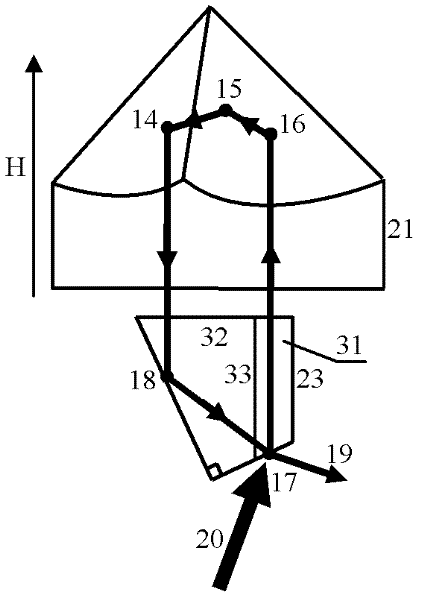

[0031] exist image 3 In the illustrated embodiment, the ring resonator is composed of two optical elements, a corner cube prism 21 and a thermally bonded laser crystal 23 . The corner cube is an optical element with the characteristic that the direction of the outgoing beam is parallel to the direction of the incident beam, and the corner cube is made of an optical medium (for example, fused silica glass) with Faraday magneto-optical properties. . Applied magnetic field H along image 3 The directions shown apply to the corner cube 21 . Applying an external magnetic field to the corner cube prism 21 not only provides greater freedom in selecting magneto-optical materials, but also facilitates the fixed installation of the magnet, for example, the corner cube prism 21 can be directly placed in the inner ring of the ring magnet . Using semiconductor laser pumping source 20 along image 3 The thermally bonded laser crystal 23 is pumped through the end face of the reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com