Force position servo control system for automatically cleaning carbon bowl of anode carbon block for aluminum electrolysis

A servo control system and anode carbon block technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as heavy workload, large personnel mobility, and potential safety hazards, and achieve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

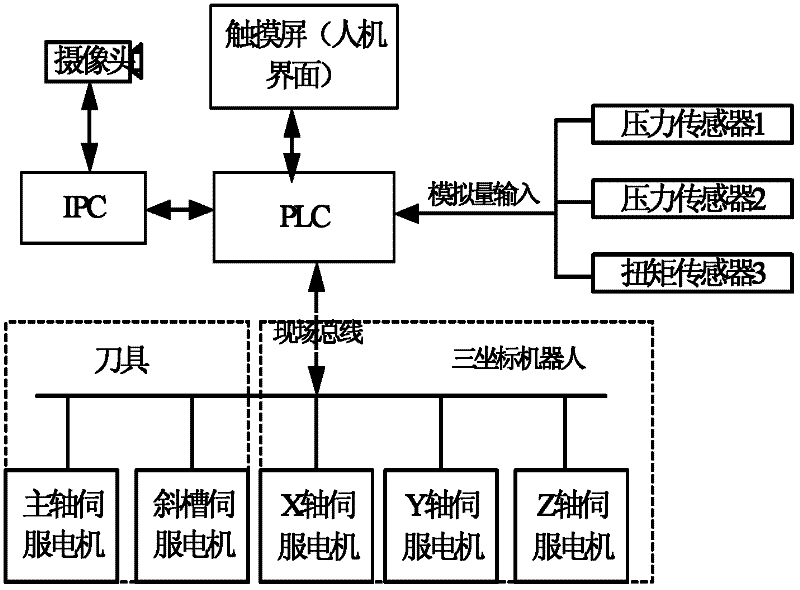

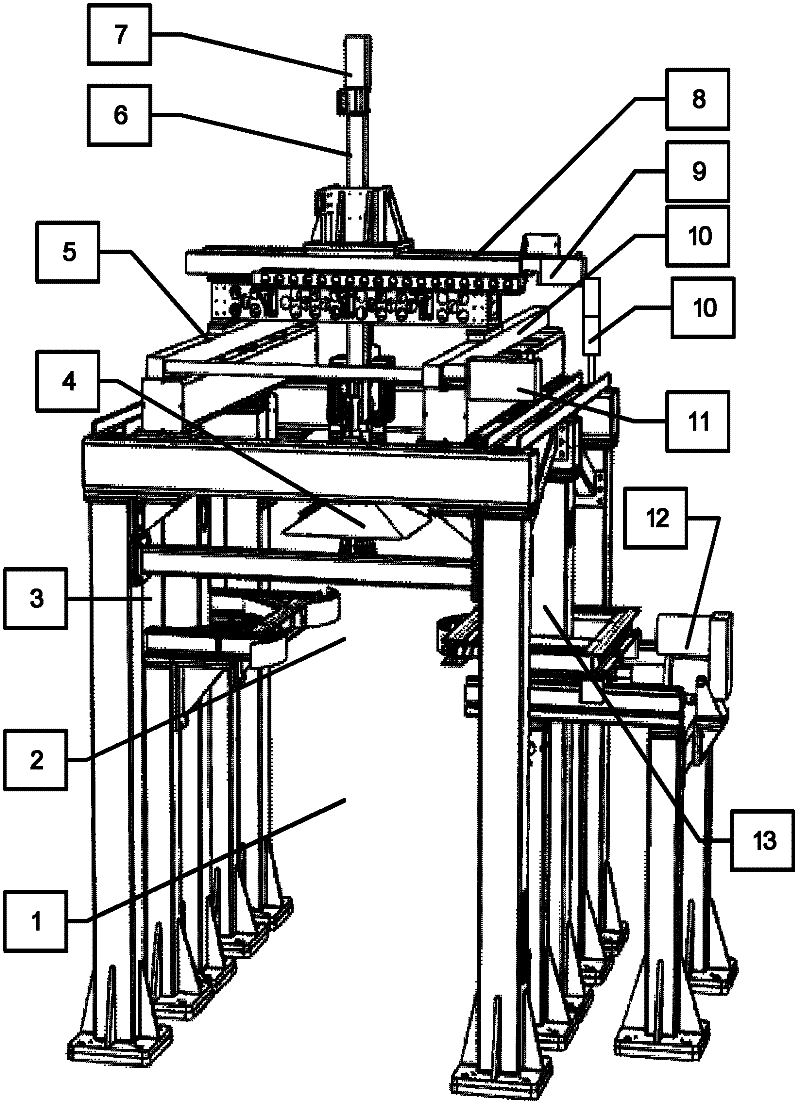

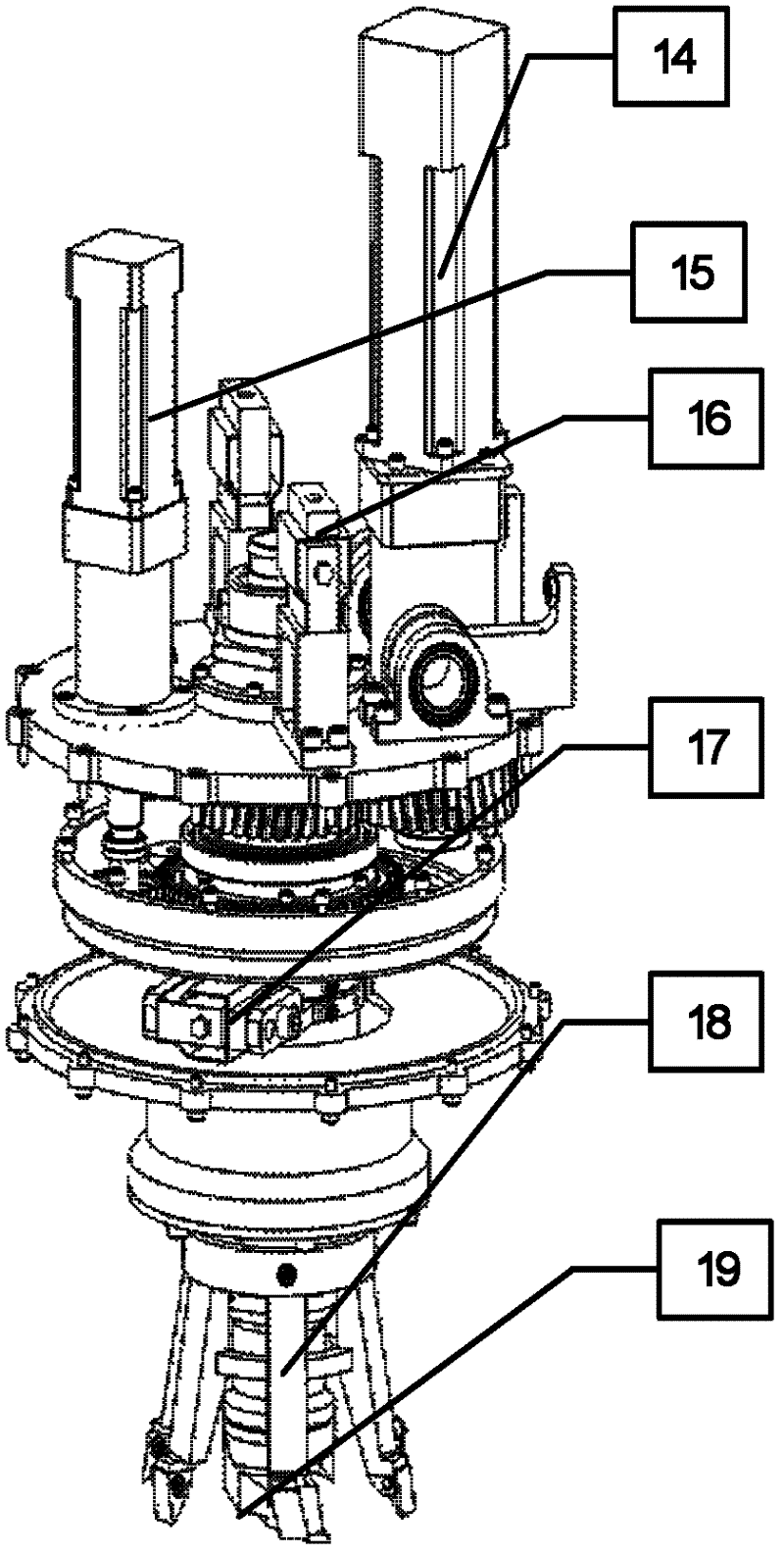

[0030] The force position servo control system of the present invention realizes the automatic cleaning of the anode carbon block carbon bowl for aluminum electrolysis, realizes the fully automatic cycle operation, fault diagnosis and protection functions of the carbon bowl cleaning system, and uses a special control system and control method to realize its functions . The control system combines image recognition technology and field bus technology to solve the problem of charcoal bowl coordinate identification and positioning. At the same time, the cutting force measurement component is used to realize the mixed control of the force and position of the charcoal bowl cleaning tool. Simultaneous cleaning of the chute, while the force measurement component also provides monitoring data for fault diagnosis and self-protection of the cleaning process. The system realizes all the process control, motion control and force feedback control algorithms through the PLC control unit. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com