Synthetic method of iron silicon molecular sieve with MFI structure

The technology of an iron-silicon molecular sieve and a synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite and the like, can solve the problems of easy loss, complicated operation and high cost, and achieve the effects of short production cycle, simple operation and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

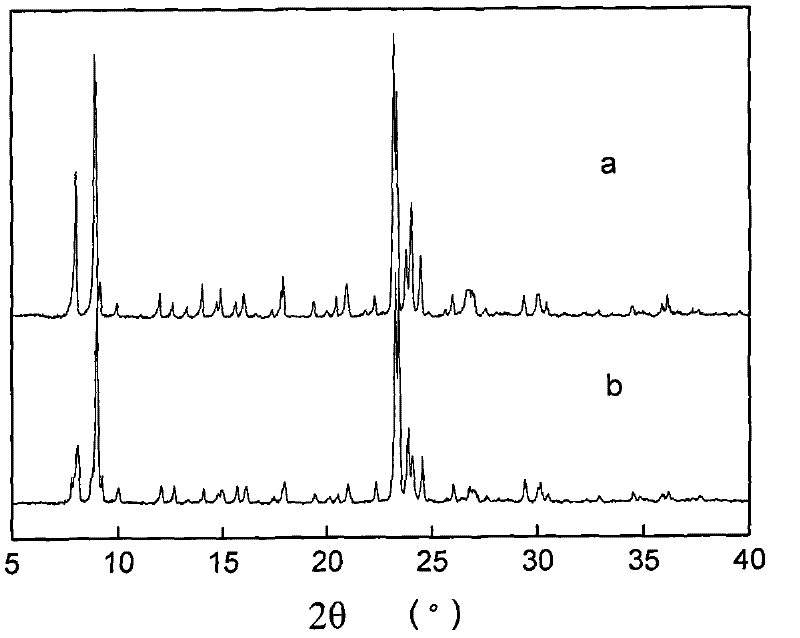

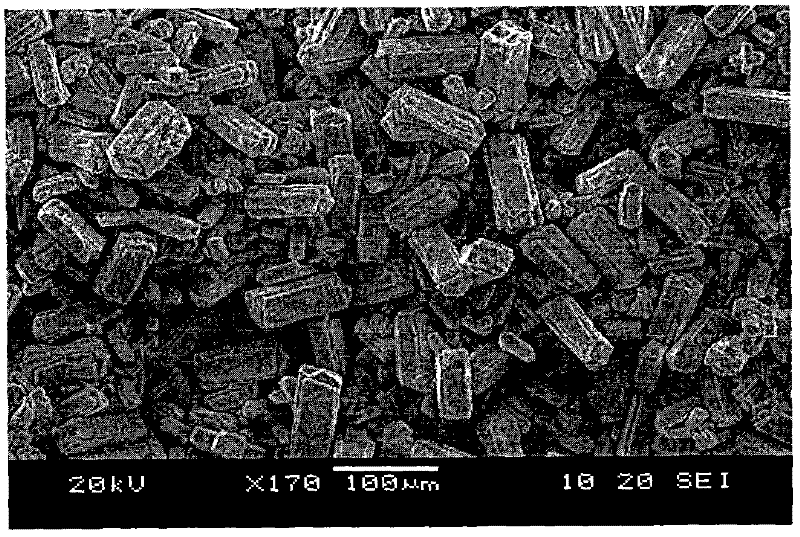

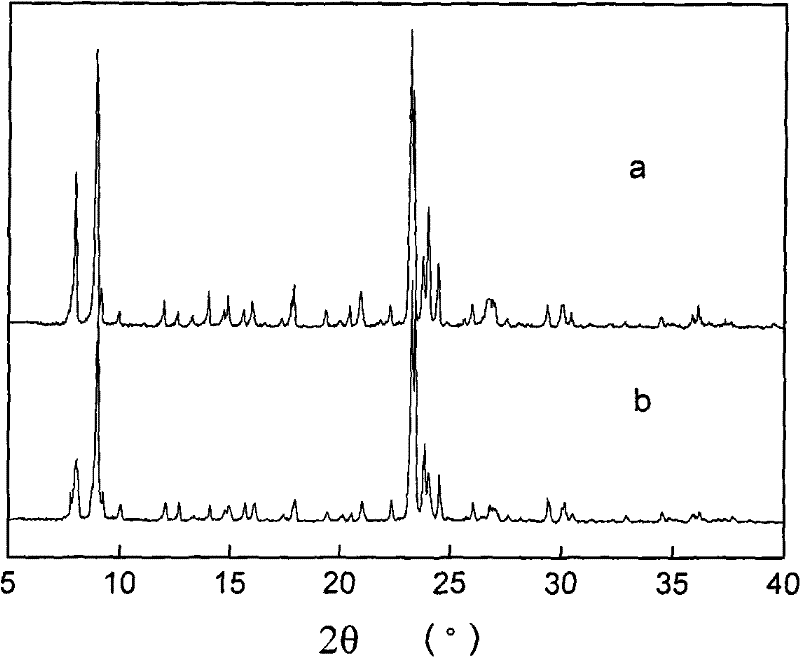

Image

Examples

preparation example Construction

[0014] A method for synthesizing iron-silicon molecular sieve with MFI structure, characterized in that: the synthesis method includes the following steps:

[0015] Step 1: Weigh the silicon source, iron source, sodium hydroxide and organic template according to the stoichiometric ratio;

[0016] Step 2: Under stirring at room temperature, the substances in Step 1 are added to deionized water in sequence and mixed uniformly to form a mixture;

[0017] Step 3: Transfer the mixture in Step 2 to a closed hydrothermal reactor, and crystallize for 3 to 7 days under the conditions of a temperature range of 140°C to 190°C to obtain crude iron silicate crystals;

[0018] Step 4: Take the crude iron-silicon molecular sieve crystal product, and obtain the iron-silicon molecular sieve product through separation, washing, drying and roasting procedures.

[0019] The molar ratio of silicon source, iron source, sodium hydroxide, organic template agent and deionized water is 1.00:0.05~0.25:3.60:0.07~0...

Embodiment 1

[0021] A method for synthesizing Fe-Si molecular sieve with MFI structure. The steps are as follows: Under stirring at room temperature, according to the molar ratio of raw materials n(SiO 2 ): n(Fe 2 O 3 ): n(Na 2 O): n(HAD): n(H 2 O) = 1.00: 0.05: 3.60: 0.225: 30 The silicon source (fumed silica or silica sol), iron source (Fe(NO 3 ) 3 ·9H 2 O or FeSO 4 .7H 2 O), sodium hydroxide, organic template (1,6-hexamethylene diamine) and deionized water are mixed and stirred vigorously for 1 to 4 hours; after the mixture is uniform, the mixture is transferred to a closed hydrothermal reactor; After crystallization at 140°C for 7 days, the crude iron-silicon molecular sieve crystals are obtained; then, the crude iron-silicon molecular sieve crystals are taken as the crystalline product, and the finished product of the iron-silicon molecular sieve is finally obtained through separation, washing, drying, and roasting.

Embodiment 2

[0023] A method for synthesizing Fe-Si molecular sieve with MFI structure. The steps are as follows: Under stirring at room temperature, according to the molar ratio of raw materials n(SiO 2 ): n(Fe 2 O 3 ): n(Na 2 O): n(HAD): n(H 2 O) = 1.00: 0.25: 3.60: 0.30: 60 The silicon source (fumed silica or silica sol), iron source (Fe(NO 3 ) 3 ·9H 2 O or FeSO 4 .7H 2 O), sodium hydroxide, organic template (1,6-hexamethylenediamine) and deionized water are mixed and stirred vigorously for 1 to 4 hours; after the mixing is uniform, the mixture is transferred to a closed hydrothermal reactor; Under the condition of 190℃, crystallize for 3 days to obtain crude iron-silicon molecular sieve crystals. Then, the crude product of the crystalline product of the iron-silicon molecular sieve crystal is taken, and the finished product of the iron-silicon molecular sieve is finally obtained through the processes of separation, washing, drying and roasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com