Treatment method for high-stability complexing heavy metal waste water

A technology with strong stability and treatment method, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , high efficiency and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

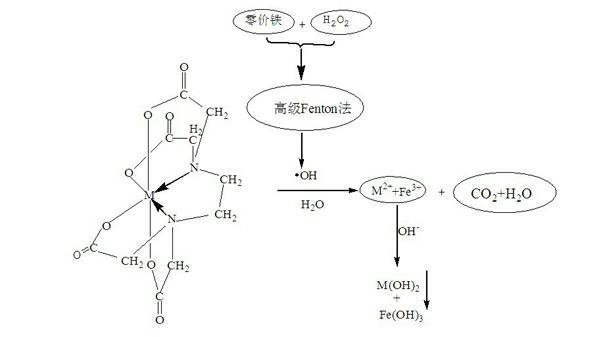

Problems solved by technology

Method used

Image

Examples

example 1

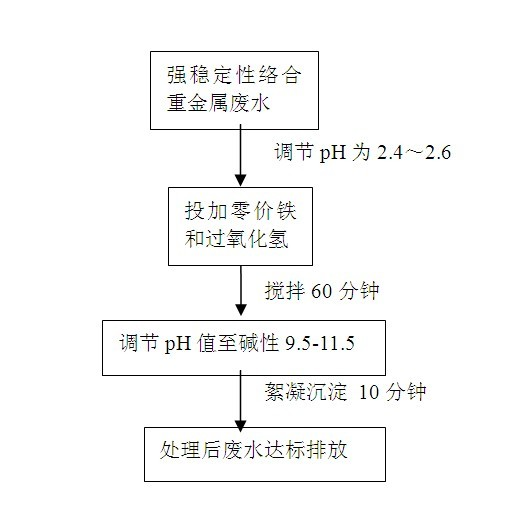

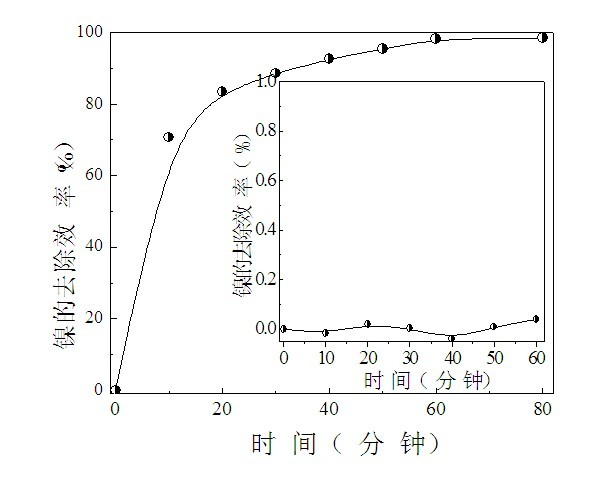

[0030] Example 1: Ni-EDTA complex wastewater

[0031] Take 100 ml at room temperature containing 50.00 mg / LNi 2+ Ni-EDTA wastewater, adjust the pH value to 2.5, add 0.2 g zero-valent iron and 0.8 ml 4.4 mol / L H successively 2 o 2 , and stirred for 60 minutes. Add sodium hydroxide precipitant to the reacted solution until the pH value is 11.5, flocculate and stir for 10 minutes, set aside, take the supernatant to measure the remaining nickel ion concentration of 0.85 mg / L, and the COD value of the solution has changed from the initial 252 dropped to 53 mg / L, and the concentration of total iron ions remaining in the solution was 0.01 mg / L.

example 2

[0032] Example 2: Cu-EDTA complexed heavy metal wastewater

[0033] Take 100 ml at room temperature containing 50.00 mg / LCu 2+ Cu-EDTA wastewater, adjust the pH value to 2.6, add 0.2 g zero-valent iron and 0.6 ml 4.4 mol / L H 2 o 2 , and stirred for 60 minutes. Add sodium hydroxide precipitant to the reacted solution until the pH value is 10, flocculate and stir for 10 minutes, put it in the net, take the supernatant to measure the remaining copper ion concentration of 0.25 mg / L, the remaining total iron ion concentration in the solution Not detected.

example 3

[0034] Example 3: Cr-EDTA complex wastewater

[0035] Take 100 ml at room temperature containing 50.00 mg / LCu 2+ Cu-EDTA wastewater, adjust the pH value to 2.4, add 0.4 g zero-valent iron and 0.8 ml 4.4 mol / L H successively 2 o 2 , and stirred for 60 minutes. Add sodium hydroxide precipitant to the reacted solution until the pH value is 9.5, flocculate and stir for 10 minutes, put it in the net, take the supernatant to measure the remaining chromium ion concentration of 1.3 mg / L, the remaining total iron ion concentration in the solution 0.03 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com