Method for extracting high-purity tea saporin

An extraction method and technology of tea saponin, applied in chemical instruments and methods, preparation of sugar derivatives, steroids, etc., can solve problems such as insoluble in water, and achieve the effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

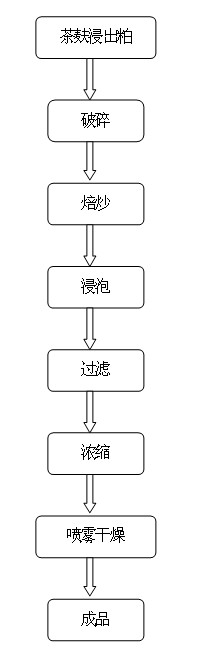

[0022] Illustrate with the daily output, the raw material is nine tons of tea dregs, and one ton of tea saponin is produced, the embodiment of the present invention is as follows:

[0023] (1) Material selection: use camellia camellia seeds to extract the oil, and then use No. 6 light gasoline to extract the residual oil as raw material, and the residual oil content is 1-1.4%;

[0024] (2) Breaking: Use a hammer crusher to evenly break the tea meal to 1-3mm, and minimize the powder;

[0025] (3) Roasting is carried out in a five-layer steam frying pan, the steam pressure is 4.5 kg, and the time is about 90 minutes, the embryo is fried to 138 ° C to solidify the impurities of the embryo;

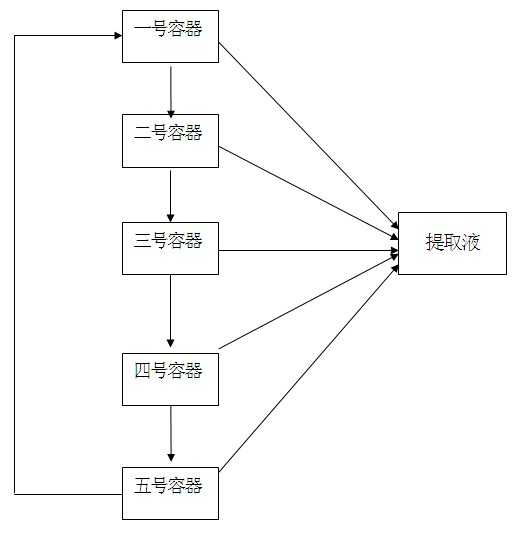

[0026] (4) Soaking: The ratio (weight ratio) of raw materials to water is 1:2.5-3.5, the time is 25-35min, the temperature is 50-60°C, and five times of reverse soaking are used. The method is: use five Container, put the new material in the No. 1 container, the first soaking liquid of the N...

Embodiment 1

[0032] (1) Material selection: use camellia camellia seeds to extract the oil, and then use No. 6 light gasoline to extract the residual oil as raw material, and the residual oil content is 1-1.4%;

[0033] (2) Breaking: Use a hammer crusher to evenly break the tea meal to 1-3mm, and minimize the powder;

[0034] (3) Roasting is carried out in a five-layer steaming wok, the steam pressure is 4.5-5 kg, the time is about 90-120min, and the embryo is fried to 138°C to solidify the impurities in the embryo;

[0035] (4) Soaking: The ratio (weight ratio) of raw material to water is 1:3, the time is 25min, the temperature is 50°C, five times of reverse soaking are adopted, the method is: use five containers, and put them in the No. 1 container Put in the new material, soak the No. 1 container for the first time as the extract, soak the liquid in the No. 1 container with clean water for the second time, and then soak the new material embryo in the No. 2 container. For the extraction...

Embodiment 2

[0041] (1) Material selection: use camellia camellia seeds to extract the oil, and then use No. 6 light gasoline to extract the residual oil as raw material, and the residual oil content is 1-1.4%;

[0042] (2) Breaking: Use a hammer crusher to evenly break the tea meal to 1-3mm, and minimize the powder;

[0043] (3), roasting, using a five-layer steaming wok, the steam pressure is 5 kg, and the time is about 120min, fry the embryo to 141 ° C, so that the impurities in the embryo are solidified;

[0044] (4) Soaking: The ratio (weight ratio) of raw materials to water is 1:2.8, the time is 35 minutes, the temperature is 60°C, and five times of reverse soaking are used. The method is: use five containers, and put them in the No. 1 container Put in the new material, soak the No. 1 container for the first time as the extract, soak the liquid in the No. 1 container with clean water for the second time, and then soak the new material embryo in the No. 2 container. For the extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com