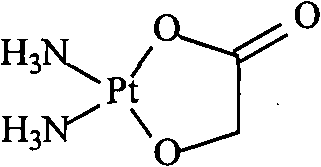

Refining method of nedaplatin

A refining method, the technology of nedaplatin, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problem that silver ions cannot be completely removed, which is not conducive to the removal of silver ions, and achieves less associated impurities, stable quality, Good process reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

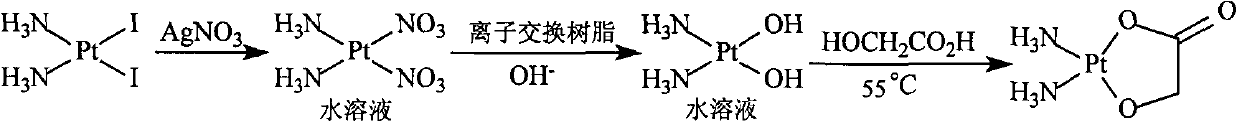

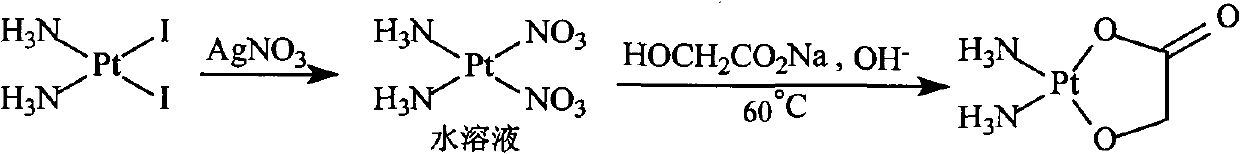

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 5.0g of neda platinum with a known silver content of 83ppm, dissolve it in 200ml of hot water at 60°C, cool to room temperature, insert the anode (graphite column, Φ0.8×2.0cm) and cathode (stainless steel plate, 3.0×2.0 cm), the pole distance is 1cm, the electrolysis voltage is adjusted to 1.75 volts, the current is 10 mA, and the electrolysis is carried out for 1.5 hours until the black deposits deposited on the stainless steel plate do not increase significantly. Filtrate, concentrate the filtrate under reduced pressure, crystallize, filter, wash the filter cake with a small amount of ice water, and dry to obtain 4.2 g of nedaplatin, with a yield of 84.0%.

[0025] Detected by atomic absorption spectrometry, the content of silver in nedaplatin is 0.58ppm; determined by high performance liquid chromatography, the content of nedaplatin is 99.38%, and the related substances are less than 1.00%.

Embodiment 2

[0027] Take 10.0 g of neda platinum with a known silver content of 200 ppm, dissolve it in 350 ml of hot water at 70 ° C, cool to room temperature, insert the anode (graphite column, Φ0.8 × 4.0 cm) and cathode (stainless steel plate, 3.0 × 4.0 cm), the pole distance is 1cm, the electrolysis voltage is adjusted to 1.75 volts, the current is 20 mA, and the electrolysis is carried out for 2.0 hours until the black deposits deposited on the stainless steel plate do not increase significantly. Filtrate, concentrate the filtrate under reduced pressure, crystallize, filter, wash the filter cake with a small amount of ice water, and dry to obtain 8.7 g of nedaplatin, with a yield of 87.0%.

[0028] Detected by atomic absorption spectrometry, the content of silver in nedaplatin is 0.76ppm; determined by high performance liquid chromatography, the content of nedaplatin is 99.25%, and the related substances are less than 1.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com