Rapid response hydrogel film glucose optical sensor

An optical sensor and fast-response technology, applied in the field of glucose optical sensors, can solve the problems that need to be further improved, the hemispherical hydrogel is not, and achieve the effects of increased swelling speed, fast response, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 0.500 g of acrylamide, 0.150 g of 3-acrylamidophenylboronic acid and 4.0 mg of azobisisobutyronitrile were dissolved in 40 mL of dimethylformamide. Deoxygenate with nitrogen gas for 30 minutes. Heated to 70°C under nitrogen protection, and reacted for 12 hours. The product was precipitated in acetone, filtered, washed with acetone several times, and dried in vacuum to obtain acrylamide-3-acrylamidophenylboronic acid copolymer.

[0028] Clean substrates (quartz, glass or polished silicon wafers) were soaked in 0.1wt% polyvinyl alcohol solution for 10 minutes, washed with water for 4 minutes, and then soaked in 0.1wt% acrylamide-3-acrylamidophenylboronic acid copolymer solution for 10 minutes. minutes, and then washed for 4 minutes. Repeat this alternate assembly process to obtain the layer-by-layer self-assembled film of polyvinyl alcohol / acrylamide-3-acrylamide phenylboronic acid copolymer.

Embodiment 2

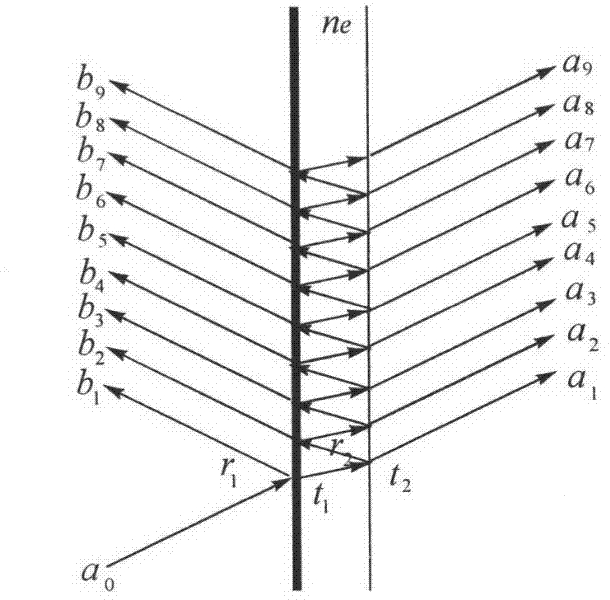

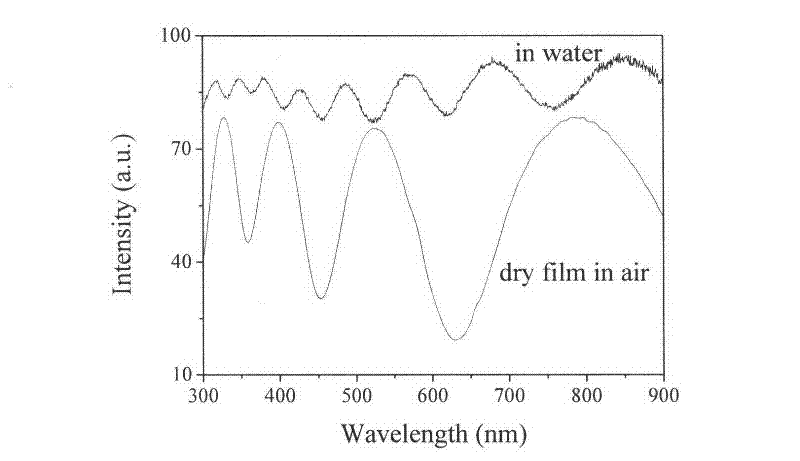

[0030] Measure the reflectance spectrum of the self-assembled film that obtains in embodiment 1 with fiber optic spectrometer, as image 3 shown. The reflection spectrum of the self-assembled film presents a series of peaks and troughs, namely Fabry-Perot fringes. The cause of the streaks is as described above. When the self-assembled film was placed in deionized water, clear Fabry-Perot fringes could still be observed, but the amplitude of the fringes decreased, and the fringe density increased due to the swelling of the film in water. ( image 3 ) These results prove that the self-assembled membrane obtained in Example 1 can swell in water and has the properties of a hydrogel film.

Embodiment 3

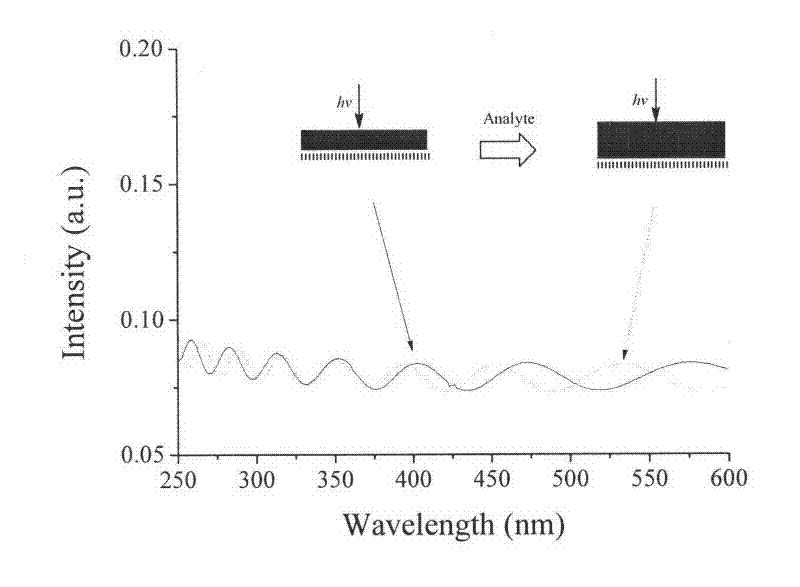

[0032] The self-assembled hydrogel membrane obtained in Example 1 was soaked in 0.050M pH8.5 phosphate buffer solution containing different concentrations of glucose at 25°C. The reflectance spectrum of the thin film is measured with a fiber optic spectrometer, such as Figure 4 shown. It can be seen that the reflectance spectrum of the self-assembled hydrogel film presents clear Fabry-Perot interference fringes, and the interference fringes move with the glucose concentration.

[0033] Depend on Figure 4 The positions of the Fabry-Perot interference fringes in , calculate the optical path length of the self-assembled hydrogel film in different glucose concentrations, such as Figure 5 shown. It can be seen that the optical path length of the self-assembled hydrogel film increases linearly with the increase of glucose concentration. That is, the concentration of glucose in the solution can be determined by the determination of the Fabry-Perot interference fringes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com