Double-view-field/double-color infrared thermal difference eliminating optical system based on harmonic diffractive optical element

A technology of optical components and optical systems, which is applied in the field of infrared thermal imaging, can solve the problems of optical system stoppage and detection rate of two-color simultaneous imaging system, and achieve the effects of reducing false alarm rate, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

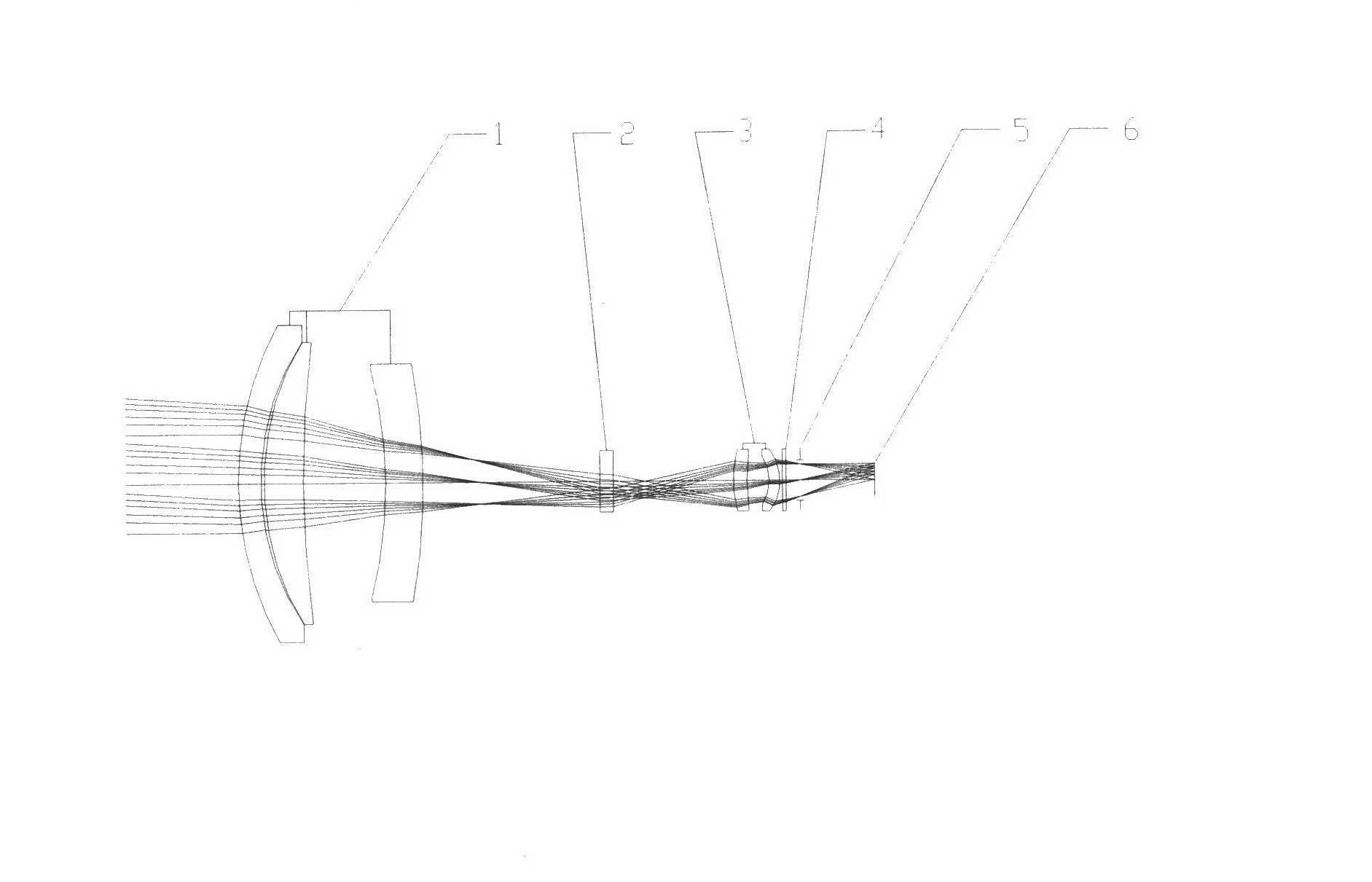

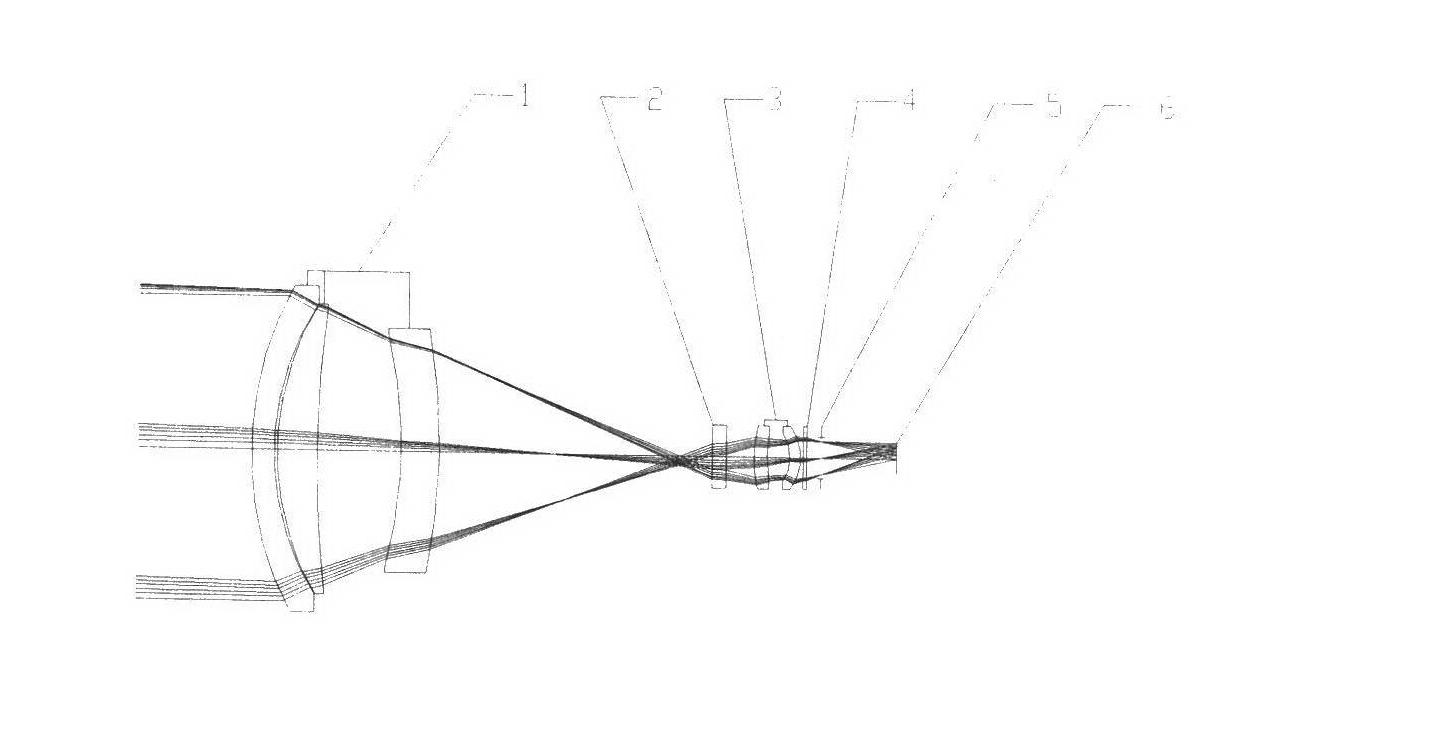

[0021] Such as figure 1 As shown, the infrared light wave emitted by the target radiation source is received by the objective lens group 1, passes through the zoom lens group 2 and reaches the relay lens group 3, and finally passes through the window glass 4 and the diaphragm 5 of the two-color infrared detector in sequence to form an image into a two-color On the infrared detector 6, the infrared radiation target can be identified by image processing and recognition of the two-color infrared detector. By axially moving the zoom lens group, the optical system can not only switch the field of view, achieve the purpose of switching between target search and target tracking modes, but also achieve adiabatic effect and enhance the environmental adaptability of the system.

[0022] The dynamic working process is given below:

[0023] Its first function is to complete the wide field of view target search: such as figure 1 As shown, when the infrared wave radiated by the target is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com