Dry carding and grading method and equipment for biomass long and short fibers

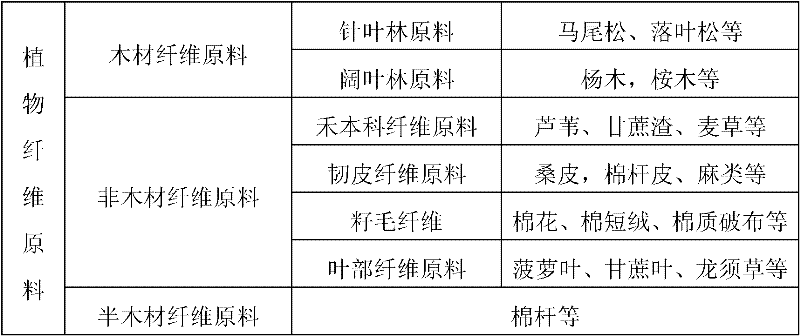

A biomass raw material and fiber technology, applied in classification, chemical instruments and methods, solid separation, etc., can solve problems that are not suitable for industrial production and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

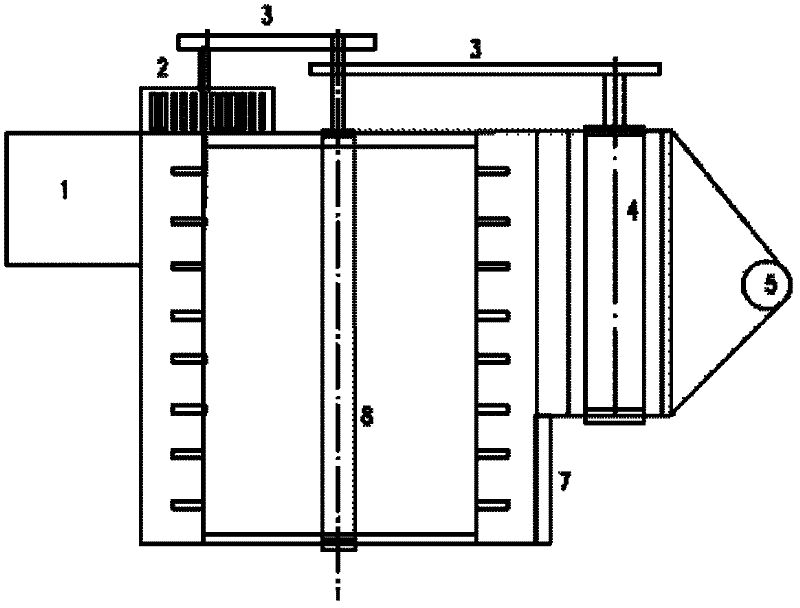

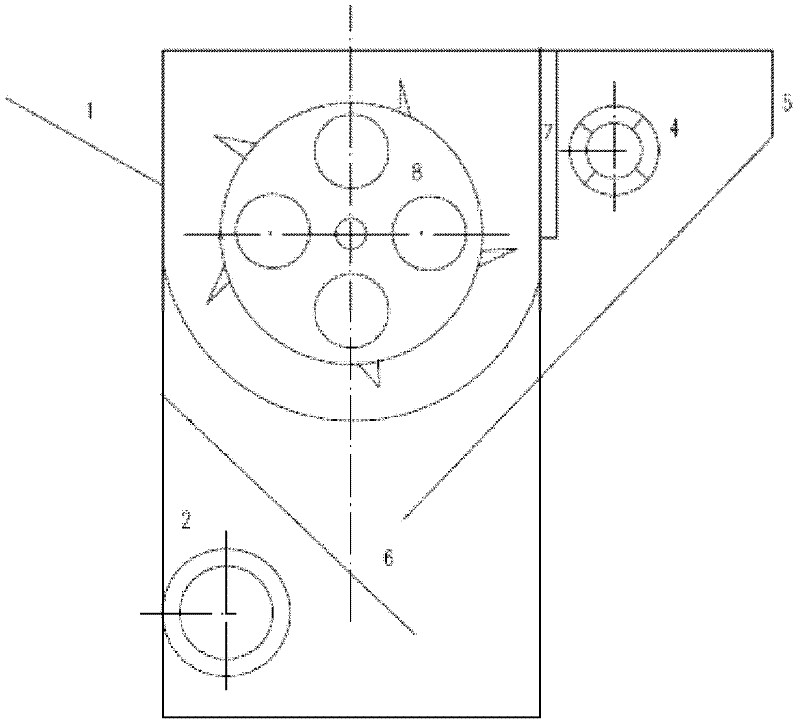

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Steam explosion pretreatment of pineapple leaf fiber coupled with fiber carding and classification

[0040] Put the pineapple leaves in the steam explosion tank, maintain the steam explosion at 170 ° C for 5 minutes, adjust the moisture content of the material after the steam explosion to 50%, then send the material into the fiber carding device, open the carding device, and adjust the speed to 600r / min , continuous treatment for 15min, respectively collect the long fiber part and the hybrid cell part (including fine fibers), of which the fiber long fiber part accounts for about 60%, which can be used as textile fibers for the next step, while the fine fiber part accounts for about 40%, which can be used for the next step. Fermentation to produce feed protein.

Embodiment 2

[0041] Example 2: Carding and grading of ramie steam-exploded degumming and fibers

[0042]Put 30kg of ramie in a 0.5 cubic steam explosion tank, maintain it at 200 ° C for 4 minutes for steam explosion, adjust the moisture content of the material after steam explosion to 50%, then send the material into the fiber carding device, open the carding device, and adjust the speed to 700r / min, continuous treatment for 20min, respectively collect the long fiber part and the heterocellular part (including fine fibers), of which the fiber long fiber part accounts for about 75%, which can be used as textile fibers for the next step, while the fine fiber part accounts for about 25% , can be fermented to produce biological fertilizers.

Embodiment 3

[0043] Example 3: Fiber Carding and Fractionation of Crop Straw

[0044] Cut the corn stalk to 3-20cm, put it in a steam explosion tank, maintain it at 160°C for 5 minutes for steam explosion treatment, adjust the moisture content of the steam-exploded material to 55%, and then send the material into the fiber carding device, turn it on Carding device, adjust the rotation speed to 500r / min, continuously process for 15min, collect the long fiber part and the miscellaneous cell part (including fine fibers) respectively, of which the fiber long fiber part accounts for about 45%, which can be used as pulping fiber for the next step. The fine fiber part accounts for about 55%, which can be fermented to produce fuel ethanol after enzymatic hydrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com