Preparation method of conductive polymer one-dimensional nanostructured array

A technology of conductive polymers and nanostructures, applied in the field of polymer materials, to achieve rapid migration, improved device performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

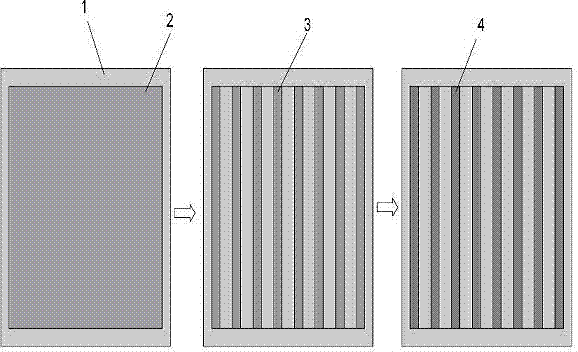

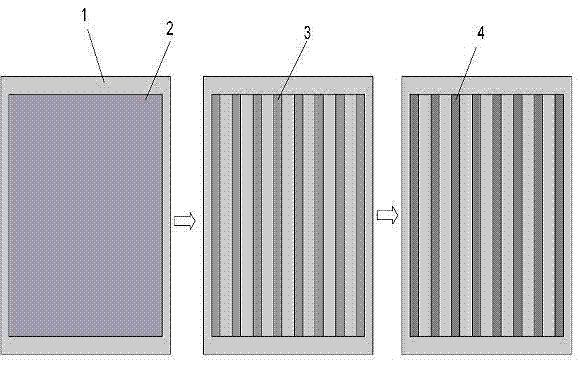

[0041] Dissolve a certain proportion of the oxidant material in the chloroform solution and stir it evenly, then use a dropper to suck a small amount of oxidant / chloroform solution and slowly drop it on the substrate placed on the spin coater, and control the spin coater's speed to prevent too much speed Film cannot be formed too slowly or the film is not dense enough. After the oxidant film with a certain thickness and uniformity is obtained, the substrate on which the oxidant film is deposited is placed in a vacuum oven for drying for a certain period of time to cure the film and drive out the chloroform solvent. To obtain an oxidant spin-coated film, such as figure 1 Shown in 2.

[0042] in figure 1 In, the oxidant spin-coated film obtained in 2 is subjected to an electron beam etching method to obtain an oxidant one-dimensional nanostructure array.

[0043] in figure 1 Then, the one-dimensional nanostructure array of the oxidant is further exposed to the atmosphere of the cond...

Embodiment 2

[0051] The monomer material is pyrrole.

[0052] The preparation process of the one-dimensional nanostructure array is similar to that of the first embodiment. Since the monomer material is pyrrole, a polypyrrole one-dimensional nanostructure array is obtained.

[0053] The etching line width is 150 nanometers, thereby obtaining a polypyrrole one-dimensional nanostructure array with a width of 150 nanometers.

Embodiment 3

[0055] The monomer material is pyrrole.

[0056] The preparation process of the one-dimensional nanostructure array is similar to that of the first embodiment. Since the monomer material is pyrrole, a polypyrrole one-dimensional nanostructure array is obtained.

[0057] The etching line width is 120 nanometers, thereby obtaining a polypyrrole one-dimensional nanostructure array with a width of 120 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com