Detection method for polychlorinated naphthalene content in electronic and electrical product rubber part

A rubber part, electronic and electrical technology, which is applied in the detection field of polychlorinated naphthalene content, can solve the problems of high content of interfering substances, difficult qualitative and quantitative analysis, high price, etc., and achieves the effect of high purification degree, sensitive method and low detection limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

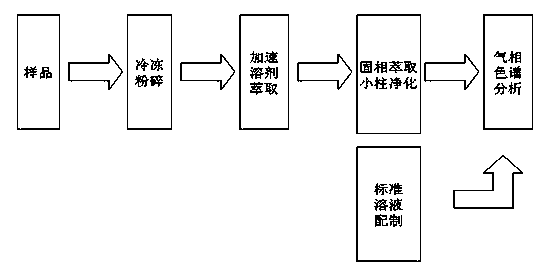

[0031] The detection method of polychlorinated naphthalene in the nitrile rubber oil seal ring provided by the present embodiment mainly comprises the following steps:

[0032] (1) Preparation of samples

[0033] Freeze and crush the nitrile rubber oil seal ring sample until the maximum particle size is less than 1 mm, and mix well to obtain a uniform sample.

[0034] (2) Extraction of PCNs

[0035] Put 0.5g of anhydrous sodium sulfate at the bottom of the extraction pool. Weigh about 1g of the pulverized sample (accurate to 0.1mg), add 0.5g of activated copper powder, stir evenly, wrap it with filter paper and put it into the extraction pool, fill the remaining space of the extraction pool with diatomaceous earth, put Into the accelerated solvent extraction apparatus, use toluene as the solvent for accelerated solvent extraction, set the amount of solvent to 20mL, the extraction temperature to 120°C, the extraction pressure to 150bar, static extraction mode, cycle times 3...

Embodiment 2

[0057] The present embodiment provides the detection method of polychlorinated naphthalene in the styrene-butadiene rubber insulating sheet, mainly comprises the following steps:

[0058] (1) Preparation of samples

[0059] Freeze and crush the styrene-butadiene rubber insulating sheet until the maximum particle size is less than 1 mm, and mix well to obtain a uniform sample.

[0060] (2) Extraction of PCNs

[0061] Put 0.3g of anhydrous sodium sulfate at the bottom of the extraction pool. Weigh about 1g of the pulverized sample (accurate to 0.1mg), add 0.3g of activated silver powder, stir evenly, wrap it with filter paper and put it into the extraction pool, fill the remaining space of the extraction pool with diatomaceous earth, put On the accelerated solvent extraction apparatus, toluene was used as the solvent for accelerated solvent extraction, the solvent dosage was set to 15mL, the extraction temperature was 150°C, the extraction pressure was 100bar, the static extr...

Embodiment 3

[0083] The detection method of polychlorinated naphthalene in the ethyl styrene rubber O type sealing ring that the present embodiment provides, mainly comprises the following steps:

[0084] (1) Preparation of samples

[0085] Freeze and crush the ethylstyrene rubber O-ring until the maximum particle size is less than 1 mm, and mix to obtain a uniform sample.

[0086] (2) Extraction of PCNs

[0087] Put 0.1g of anhydrous sodium sulfate at the bottom of the extraction pool. Weigh about 1g of the pulverized sample (accurate to 0.1mg), add 0.8g of activated lead powder, stir evenly, wrap it with filter paper and put it into the extraction pool, fill the remaining space of the extraction pool with diatomaceous earth, put In the accelerated solvent extraction apparatus, toluene was used as the solvent for accelerated solvent extraction, the solvent dosage was set to 10mL, the extraction temperature was 80°C, the extraction pressure was 120bar, in static extraction mode, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com