Process for forming medium-voltage cable with copper strip as shield and optical fiber for temperature measurement as well as compounded with communication

An optical fiber temperature measurement and copper tape shielding technology, applied in power cables, cable/conductor manufacturing, cables, etc., can solve problems such as losses, achieve power supply security, avoid large-scale power outages, and improve the effect of integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

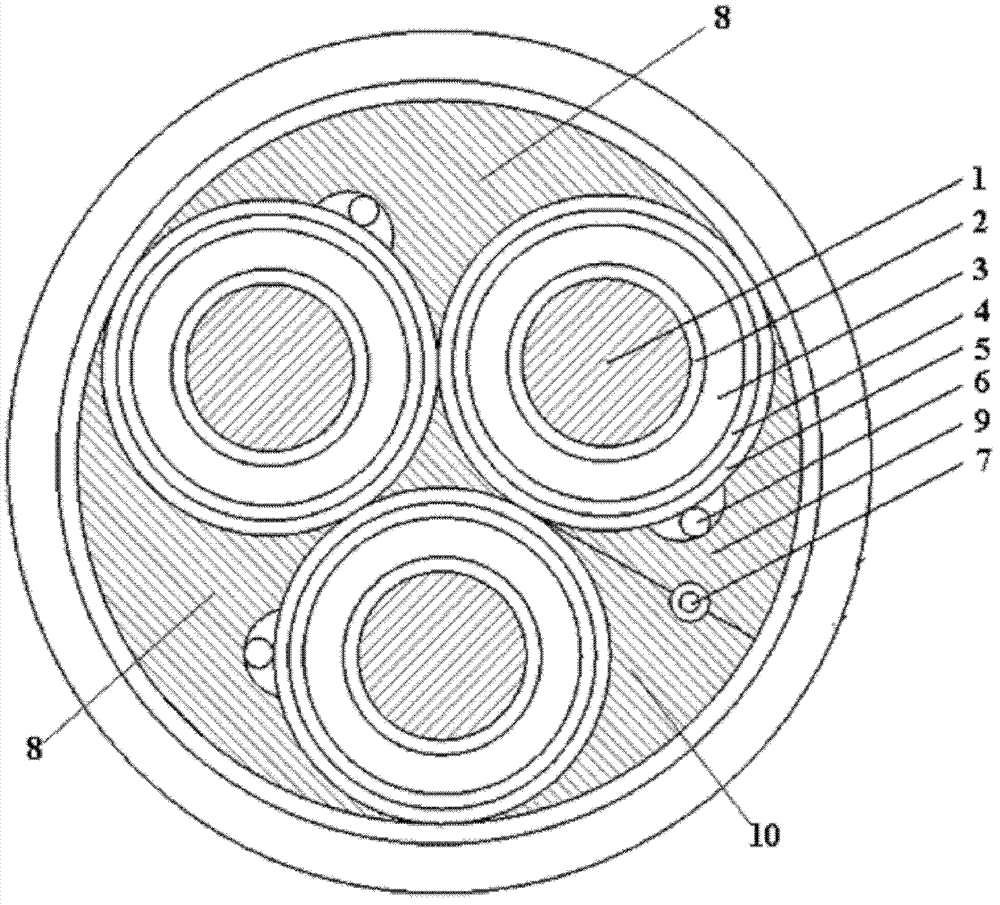

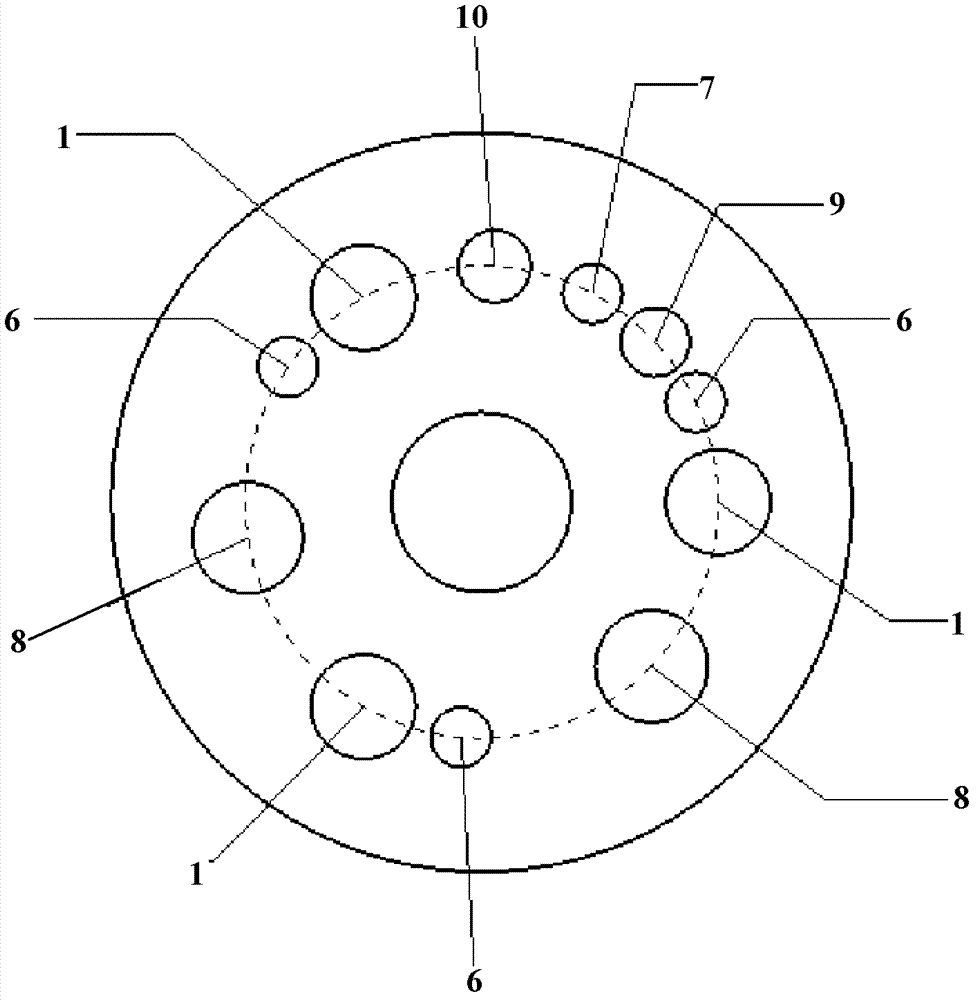

[0032] Embodiment: a copper tape shielded optical fiber temperature measurement and communication composite medium voltage cable cabling process,

[0033] Step 1. Twisting several copper monofilaments on the surface of the central copper monofilament to form a compact circular conductor 1; the following forms can be adopted: 1+6 two-layer structure, 1+6+12 three-layer structure, 1+ 6+12+18 four-layer structure, etc., the twisting direction of the copper monofilament in the outermost conductor layer is right, and the twisting direction of the copper monofilament between the inner layer and the layer is opposite, and the pitch of the multiple twisting is controlled at 143~195mm .

[0034] Step 2, produce a three-layer co-extruded composite layer consisting of a conductor shielding layer, a cross-linked polyethylene layer 3, and an insulating shielding layer 4 on the surface of the circular conductor after step 1 by means of peroxide crosslinking ;

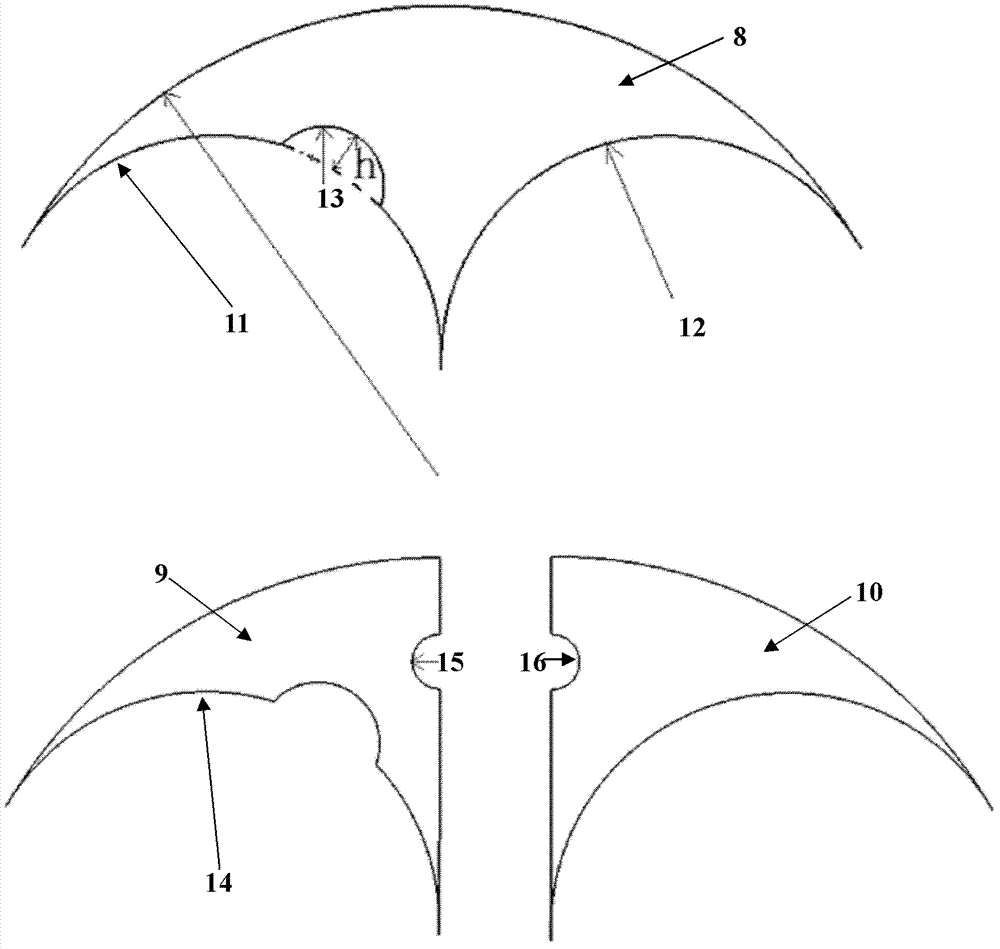

[0035] Step 3, wrapping the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com