Negative electrode material for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery using same

A non-aqueous electrolyte and secondary battery technology, applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems of low crystallinity of amorphous carbonaceous particles, increase of irreversible capacity of amorphous carbon particles, etc., and achieve rapid charging Effects of discharge characteristics, excellent performance, and high cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] (Production of carbon material A)

[0163] As the raw material graphite, the following flaky graphite particles produced in nature were used: the interplanar distance (d002) of the 002 plane measured by the wide-angle X-ray diffraction method is Lc is Above, the tap density is 0.46g / cm 3 , 1360cm in the argon ion laser Raman spectrum -1 Nearby peak intensity and 1580cm -1 The ratio of nearby peak intensities, that is, the Raman R value is 0.13, the average particle size is 28.7μm, and the true density is 2.27g / cm 3 .

[0164] Using the Hybridization System manufactured by Nara Machinery Manufacturing Co., Ltd., the above-mentioned flaky graphite particles were continuously processed at a processing speed of 20 kg / hour under the condition of a rotor peripheral speed of 60 m / s and 10 minutes. The spheroidization process was performed while applying damage to the surface of the graphite particles. Then, fine powder is removed by performing classification treatment....

Embodiment 2

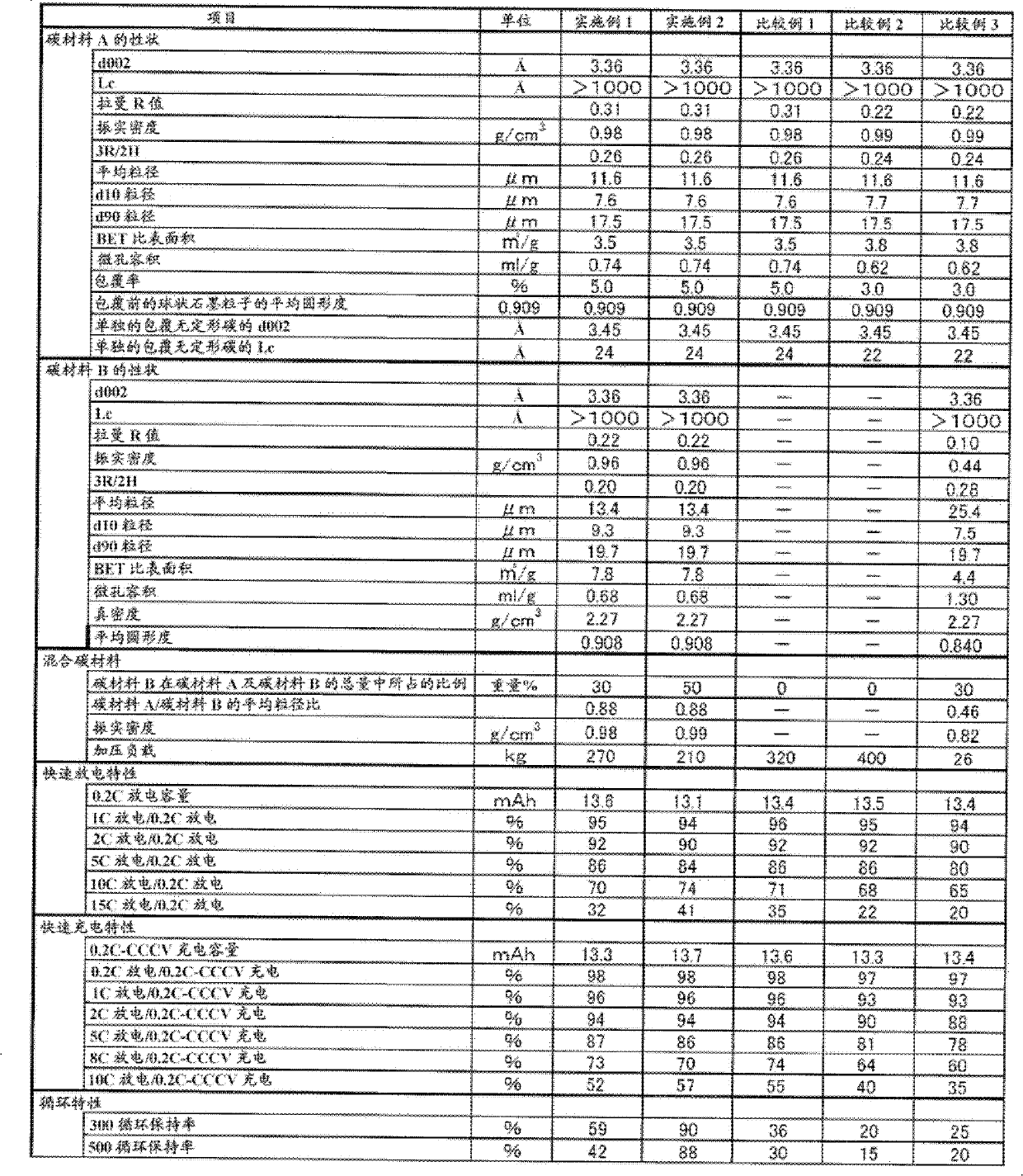

[0187] The same operation as in Example 1 was carried out except that the ratio of the carbon material B to the total amount of the carbon material A and the carbon material B was 50% by weight. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com