Split-phase lead-coated submarine cable

A submarine cable and phase separation technology, which is applied in the direction of submarine cables, power cables, cables, etc., can solve the problems of reduced cable life, complicated operation, poor waterproof and aging performance, etc., to eliminate electric induction potential, improve safety factor, The effect of preventing damage to the optical cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

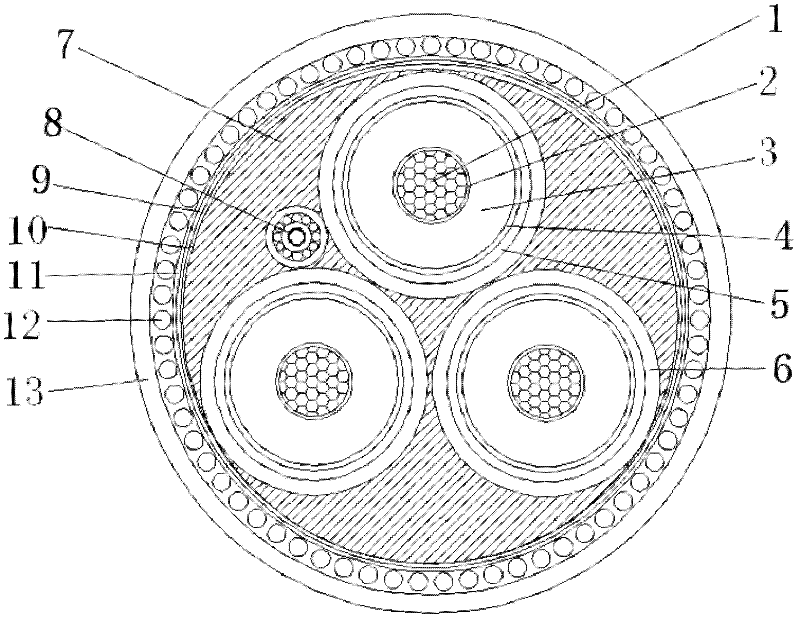

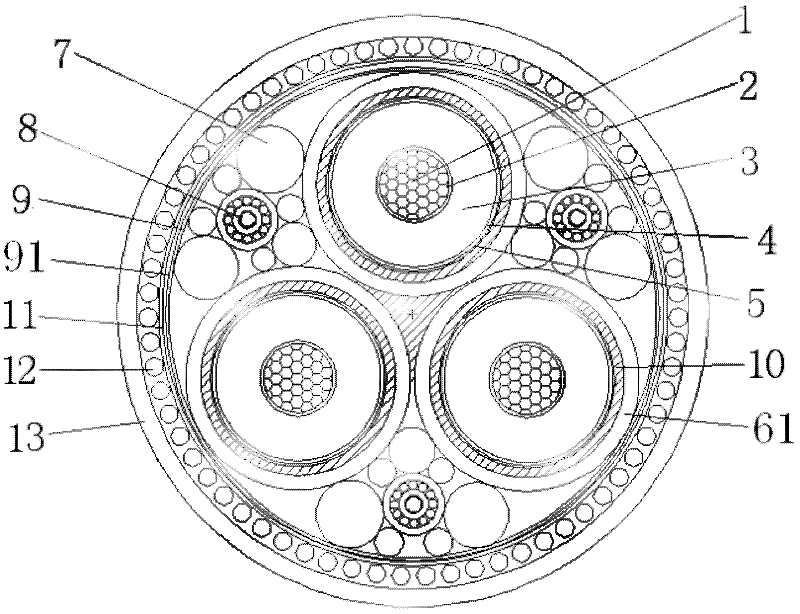

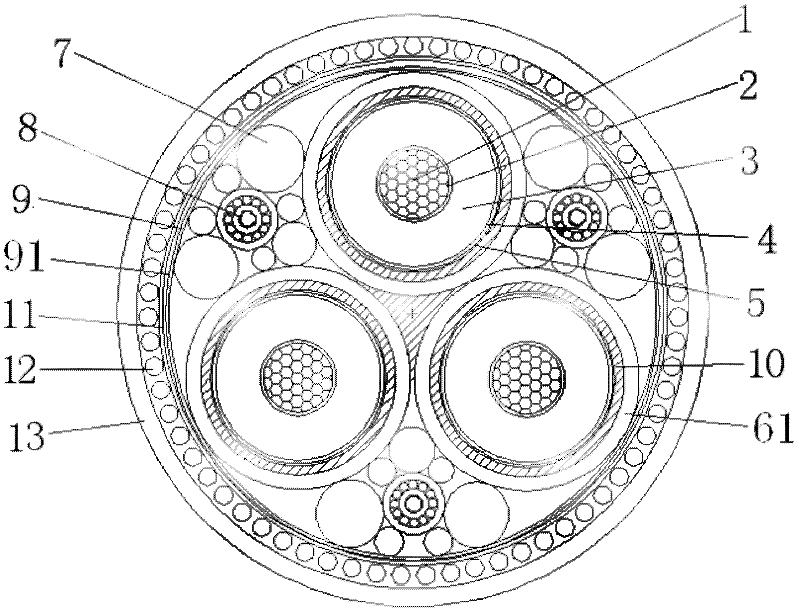

[0028] like figure 2 As shown, the phase-splitting lead-clad submarine cable of the present invention includes three power cables, and the power cables are mainly composed of a water-blocking conductor 1 and an inner shielding layer 2, an insulating layer 3, The outer shielding layer 4 and the water blocking buffer layer 5 are composed.

[0029] The water-blocking conductor 1 is mainly composed of copper or aluminum and water-blocking tape or other water-blocking materials, which are used to transmit electric current, can withstand certain mechanical forces, and can play the role of water-blocking and water-absorbing, so as to minimize the insulation water The birth of the tree.

[0030] The inner shielding layer 2 is composed of a smooth inner shielding material, and the outer shielding layer 4 is composed of a smooth outer shielding material. The inner shielding layer 2 and the outer shielding layer 4 are mainly used for heat shielding and electric field shielding, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com