Epitaxy production method of light emitting diode (LED)

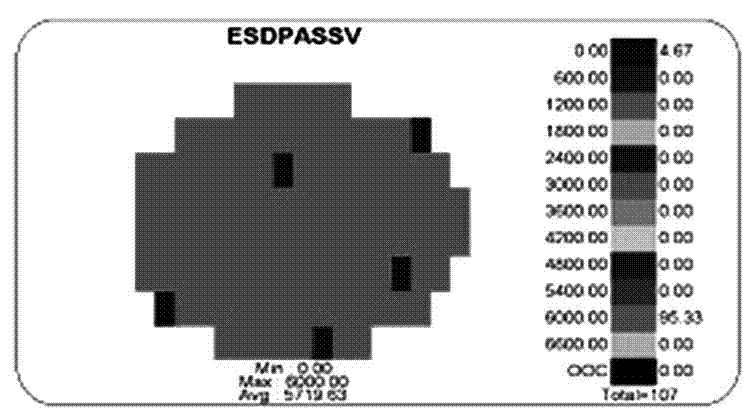

A technology for light-emitting diodes and production methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of poor current expansion capability and small internal capacitance of GaN-based LEDs, and achieves improved antistatic capability, improved luminous efficiency, and increased luminous efficiency. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

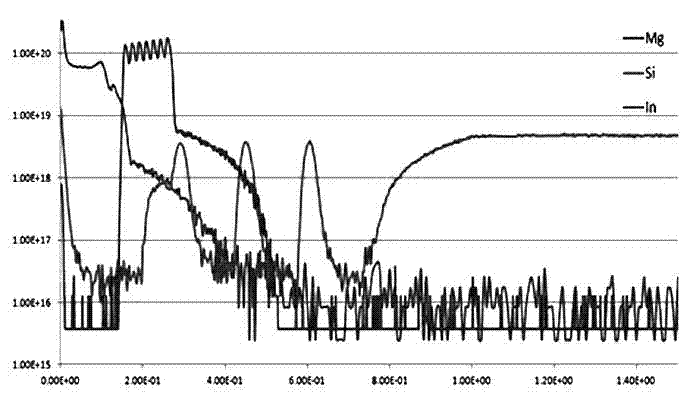

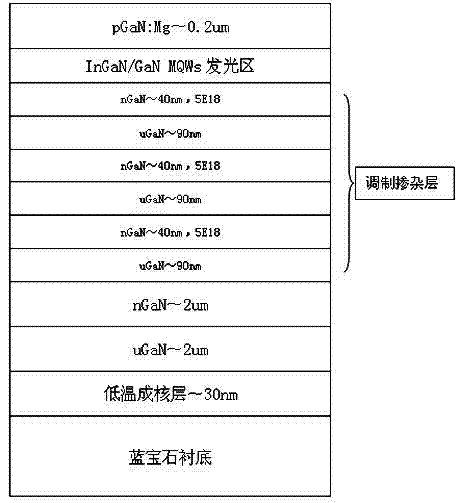

[0022] 1. Principles of the epitaxial processing steps of light-emitting diodes:

[0023] 1. The low-temperature gallium nitride nucleation layer grown on sapphire, silicon carbide, silicon, gallium arsenide, zinc oxide or lithium aluminate substrate, the growth temperature is 500-600 ℃, the growth pressure is 10000-90000Pa, the growth thickness 0.01-0.1 μm.

[0024] 2. Growing an unintentionally doped GaN layer on the low-temperature gallium nitride nucleation layer, the growth temperature is 900-1200°C, the growth pressure is 10000-60000Pa, and the growth thickness is 1-5μm.

[0025] 3. N-type doped GaN is grown on the unintentionally doped GaN layer, the growth temperature is 1000-1100°C, the growth pressure is 10000-60000Pa, the growth thickness is 1-5μm, and the N-type doping element is Si or Other elements that can act as N-type impurities in GaN.

[0026] 4. Grow N-type doped GaN and non-doped GaN alternating periodic structure layers on N-type doped GaN, the growth t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Growth pressure | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com