Motor controller for electric automobile

A technology for motor controllers and electric vehicles, applied in electrical components, output power conversion devices, cooling/ventilation/heating transformation, etc., can solve the problem of poor isolation between the control board and the drive board, poor heat dissipation of the drive module, Problems such as insufficient sealing of the controller can achieve the effect of improving the installation process, saving space and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

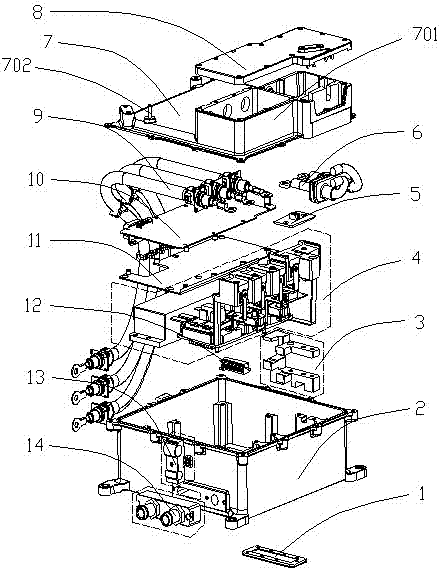

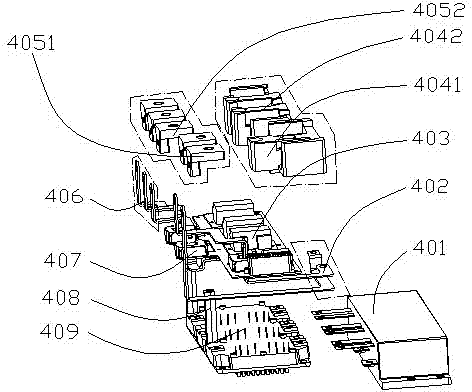

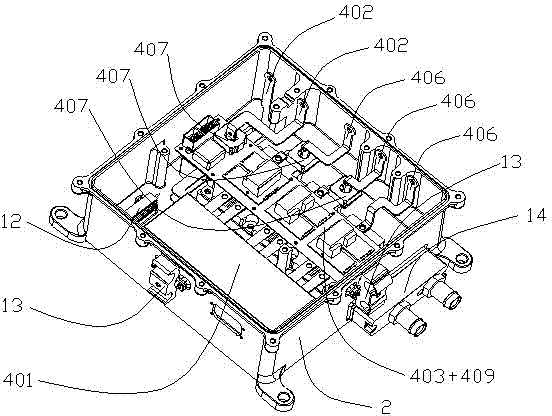

[0025] like figure 1 , Image 6 The shown electric vehicle motor controller includes a main casing 2, a water nozzle assembly 14 installed on the outside of the main casing 2, a drive module assembly 4 installed in the lower part of the main casing 2, The control board 10, the DC bus 6 and the AC bus 9 electrically connected with the drive module assembly 4, and the upper casing 7 installed on the main casing 2; the main casing 2 is integrally cast with aluminum alloy material, and the upper casing 7 It is reliably sealed with the main casing 2 by a sealing ring; a metal mesh electromagnetic shielding layer is provided between the insulating layers of the DC bus bar 6, the positive and negative DC bus bars are integrally sealed, and a metal mesh electromagnetic shielding layer is also provided between the insulating layers of the AC bus bar 9 layer, which is crimped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com