Method for modifying microporous membrane wettability by utilizing low pressure-forced Cassie state effect

A microporous membrane and wettability technology, which is applied in the field of changing the wettability of microporous membranes, can solve problems such as surface superhydrophobicity failure, superhydrophobicity failure, etc., to reduce free energy, reduce failure probability, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the microporous membrane adopts Millipore NY11 nylon microporous membrane, and its micropore diameter is 11 μm.

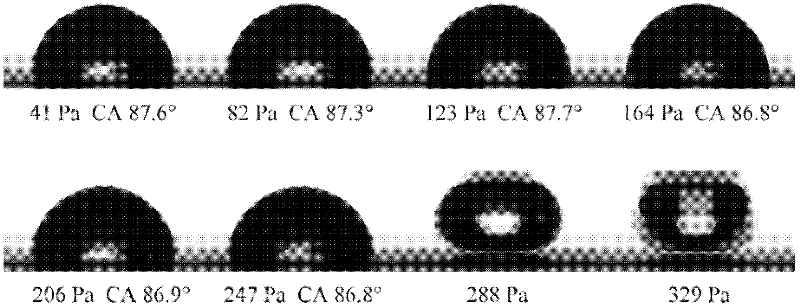

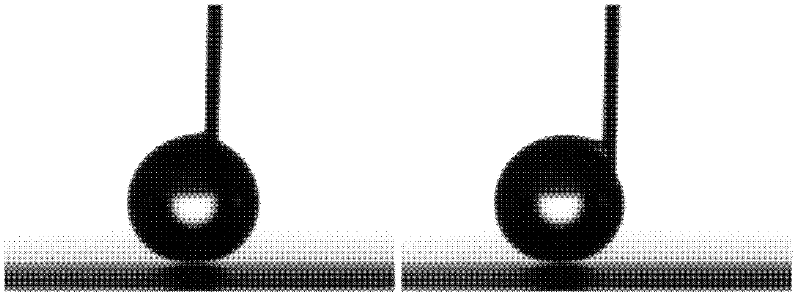

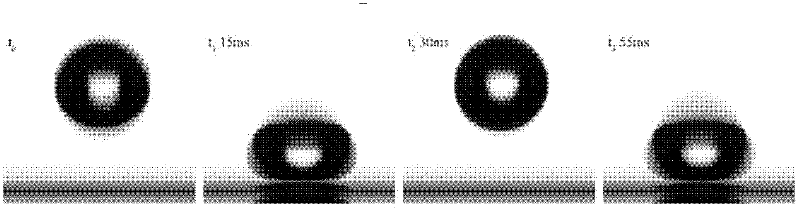

[0024] After installing the Millipore NY11 nylon microporous membrane on the stabilizer membrane fixing platform, use the positioning screws to fix the stabilizer membrane fixing platform on the optical contact angle measuring instrument. After adjusting the level of the film fixing platform and the contact angle measuring instrument, gradually increase the pressure of the stabilized pressure source, and record the water droplet shape on the surface of the microporous film to obtain figure 1 . When the relative pressure on both sides of the microporous membrane reaches 288Pa, the water droplets on the surface of the microporous membrane change from the Wenzel state to the pressure forced Cassie state, such as figure 1 Shown. At this time, the microporous membrane exhibits good anti-water sticking properties, such as figure 2 As shown, and t...

Embodiment 2

[0026] In this example, the microporous membrane is the same as the microporous membrane in Example 1, and both use Millipore NY11 nylon microporous membrane with a micropore diameter of 11 μm. The specific method is basically the same as in Example 1, except that CF is used 4 Plasma is used to modify the surface of the microporous membrane as follows:

[0027] First, adopt CF 4 Plasma modifies the surface of the Millipore NY11 nylon microporous membrane to reduce the surface free energy of the microporous membrane. The specific process is: fix the microporous membrane in the vacuum chamber of the plasma treatment instrument, adjust the working pressure of the vacuum chamber to 20Pa and power 75W, processing time 30min. Then, the modified microporous membrane was installed on the stabilized membrane fixed platform, and its forced Cassie state critical pressure was determined to be 164Pa. Then, after the modified microporous film is installed on the stabilizer film fixing platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com