Multifunctional oil-water separating material and preparing method and application thereof

An oil-water separation and multi-functional technology, applied in the field of water treatment, can solve the problems of inability to achieve complete water purification, low utilization efficiency of solar energy restricting the application of ultraviolet photocatalysts, lack of Raman detection of pollutants, etc., to improve Raman detection Sensitivity, good recovery and reuse, and the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

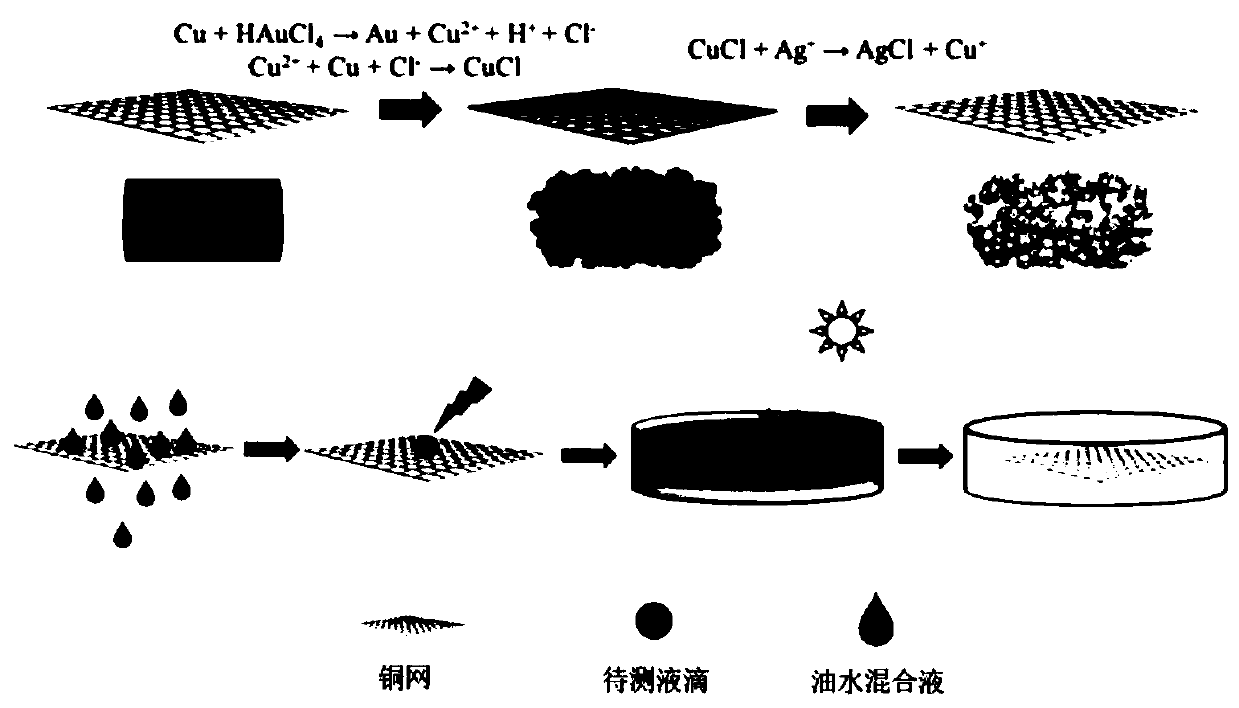

[0033] Example 1: Preparation of a copper mesh integrating three functions of oil-water separation, dye detection and photodegradation

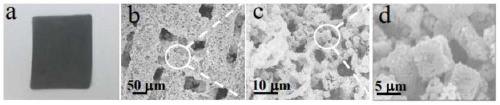

[0034] (1) Pretreatment of the copper mesh: use hydrochloric acid solution, acetone solution and deionized water to ultrasonically clean the surface impurities of the copper mesh respectively, after treatment, soak the copper mesh in 0.01M chloroauric acid solution for 1 to 2 hours and take it out The copper mesh is washed with ultrapure water to remove surface impurities to obtain a copper mesh loaded with Au / CuCl particles;

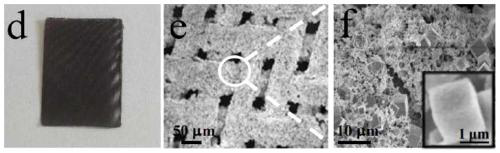

[0035] (2) Soak the copper mesh loaded with Au / CuCl particles in a 0.01M silver nitrate solution for 1 to 2 hours, then take out the copper mesh and rinse the surface of the copper mesh with ultrapure water to obtain the copper mesh with Au / AgCl particles loaded on the surface. network;

[0036] (3) Then the surface of the copper mesh is modified with perfluorodecyl mercaptan (PFDT), a low surface energy fluorine-cont...

Embodiment 2

[0039] Example 2: The oil-water mixture containing methylene blue in the water phase and Sudan red in the oil phase is first subjected to oil-water separation and dye detection

[0040] see Figure 5 , due to the super-hydrophobic and super-oleophilic properties of the surface, the Sudan III molecules in the organic solvent are separated from oil and water as the organic solvent passes through the copper mesh, and the water phase containing methylene blue molecules remains on the surface of the copper mesh to maintain a droplet shape. The volatilization of the liquid droplets is finally concentrated in a small area of the noble metal hot zone, and the interference of the oil phase pollutants is finally eliminated, leaving only the Raman signal of the methylene blue molecule.

[0041] Photodegradation of the water phase after the oil-water separation of the oil-water mixture containing methylene blue in the water phase and Sudan Red in the oil phase. Under the irradiation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com