Preparation method of flexible fluoride-free super-hydrophobic coating with photothermal conversion and heat storage functions

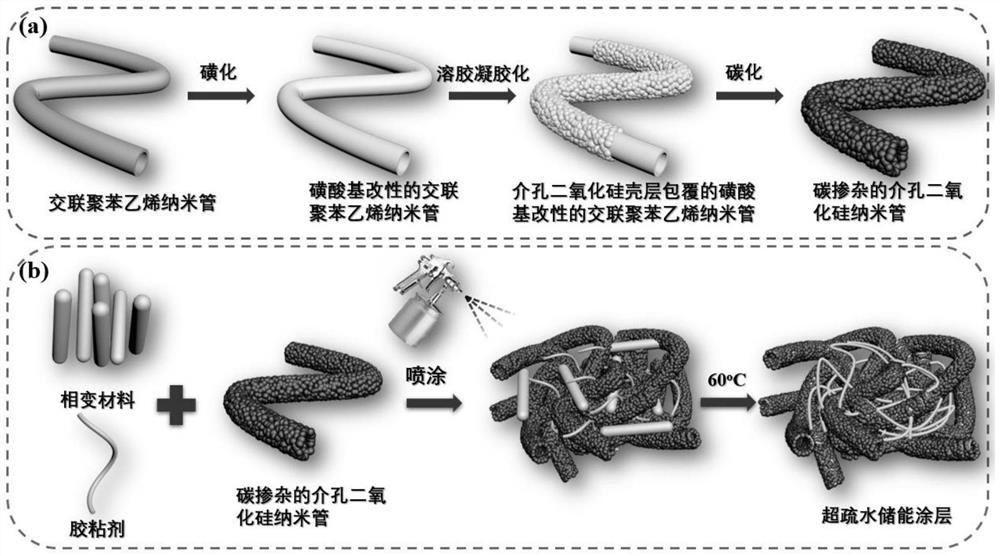

A super-hydrophobic coating, photothermal conversion technology, applied in the fields of organic, inorganic, functional materials and polymer materials, can solve the problems of inability to large-scale production and application, reduced flexibility, high price, etc., and achieve excellent photothermal conversion The effect of ability, simple construction and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Preparation of cross-linked polystyrene nanotubes

[0067] Referring to the above-mentioned cationic polymerization method, under the condition of 25°C, add 117g cyclohexane (99% purity) and 2.337g divinylbenzene successively into a 250mL three-neck flask equipped with electric stirring, and pass in argon gas, and stir for 15min. , dropwise (dropping time is 10s) 0.15g boron trifluoride diethyl ether (purity: 98%) into the there-necked flask, and increase the stirring speed to 400r / min at the same time, and react for 5min. Transfer the resulting suspension to a beaker, and after the polymer settles, pour the supernatant into a waste liquid bucket, wash the obtained product repeatedly with absolute ethanol to remove the solvent and initiator, and obtain the product after suction filtration. The final collected product is dried in an oven to obtain the cross-linked polystyrene nanotube.

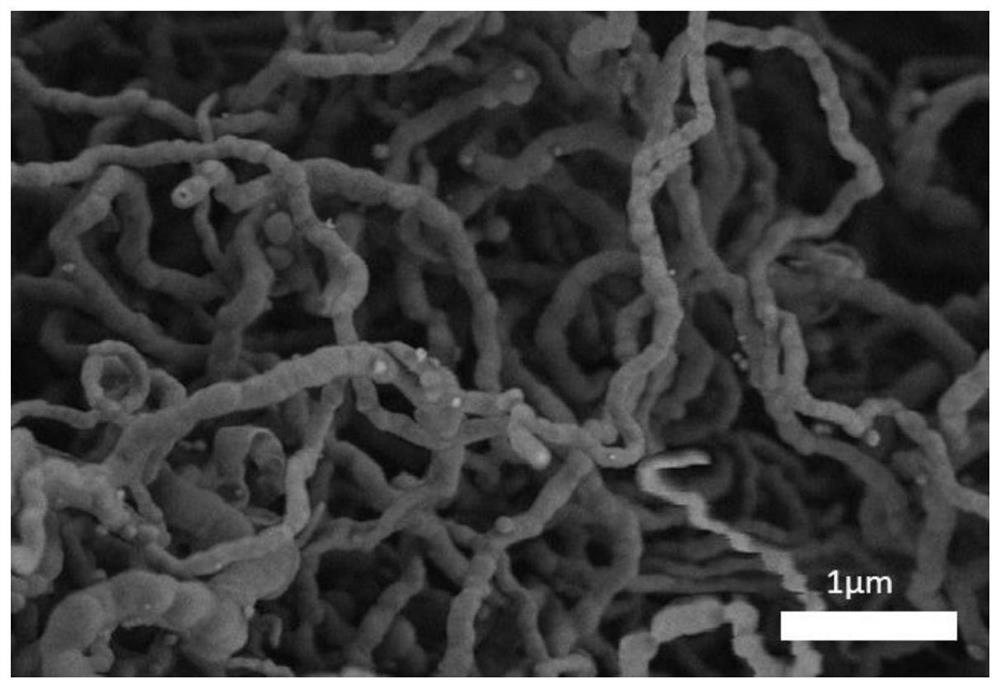

[0068] figure 2 It is a photograph obtained by scanning cross-linked polystyr...

Embodiment 2

[0093] (1) Preparation of poly(styrene-divinylbenzene) nanotubes

[0094] At 25°C, 117g of cyclohexane (99% purity), 2.337g of divinylbenzene, and 0.5g of styrene were successively added to a 250mL three-necked flask equipped with electric stirring, and an inert gas (nitrogen or argon) After stirring for 15 minutes, add 0.15 g of boron trifluoride diethyl ether (purity: 98%) dropwise into the there-necked flask (dropping time is 10 s), and increase the stirring speed to 400 r / min at the same time, and react for 5 minutes. Transfer the resulting suspension to a beaker, and after the polymer settles, pour the supernatant into a waste liquid bucket, wash the obtained product repeatedly with absolute ethanol to remove the solvent and initiator, and obtain the product after suction filtration. The finally collected product is dried in an oven to obtain poly(styrene-divinylbenzene) nanotubes.

[0095] (2) The preparation of the cross-linked poly(styrene-divinylbenzene) nanotubes mo...

Embodiment 3

[0100] (1) The preparation of cross-linked polystyrene nanotubes is the same as in Example 1 step (1);

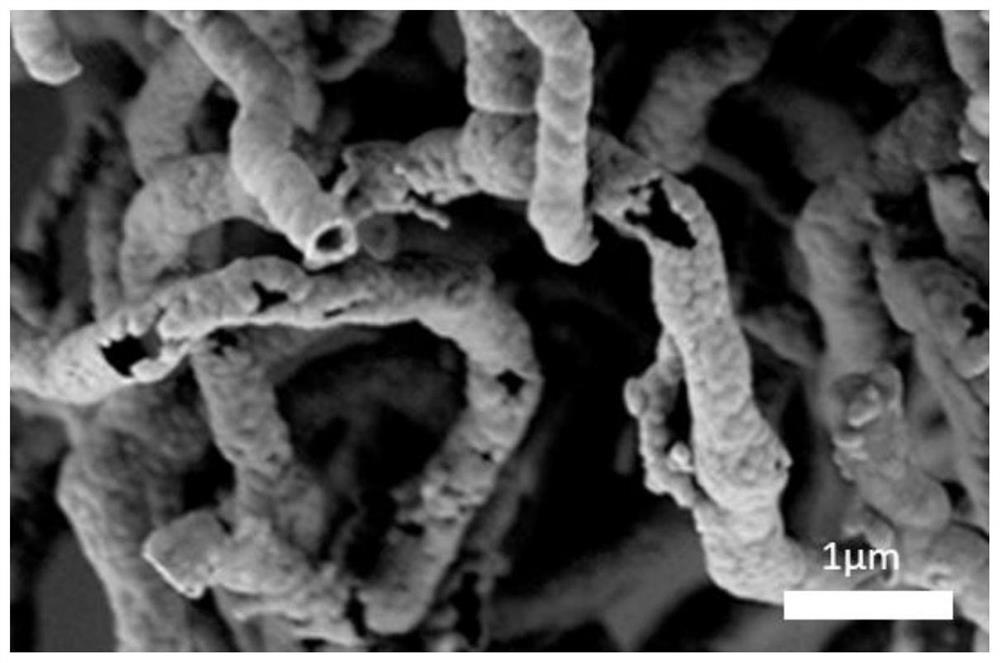

[0101] (2) Preparation of cross-linked polystyrene nanotubes modified by sulfonic acid group

[0102] Take 1 g of the dried cross-linked polystyrene nanotubes obtained in step (1) in a one-necked bottle, add 100 g of 1,2-dichloroethane (purity is 99%), soak for 2 h at 25 ° C, and take 30 g of sulfamic acid In another single-necked flask, place it in a water bath equipped with magnetic stirring for 2 hours at a temperature of 0°C, transfer the mixture obtained in the two single-necked flasks to a 500ml three-necked flask, and condense under heating in an oil bath at 80°C Reflux, react for 5 hours, cool down naturally to 20-30°C after the reaction stops, transfer the resulting suspension to a 1L beaker, add absolute ethanol to dilute, then perform suction filtration, and the product obtained is rinsed repeatedly with absolute ethanol and placed in an oven to dry , that is, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com