A kind of carbon material bead/polymer composite film and its preparation and application

A carbon material and polymer technology, applied in the field of carbon material microbeads/polymer composite film and its preparation, can solve problems such as single reflection and limited light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1: the preparation of carbon nanotube microbead / PMAA composite film

[0096] Add 5 g of carbon nanotubes (CNT) into a flask containing a mixture of concentrated sulfuric acid and nitric acid (volume ratio 3:1), and reflux at 60° C. for 3 hours under continuous stirring. The resulting suspension is repeatedly washed and separated using a semipermeable membrane (dialysis bag). Finally, water-dispersed carbon nanotube powder was obtained after drying at 80°C.

[0097] The above acidified carbon nanotube (aCNTs) powder was made into an aqueous solution with a mass fraction of 4.42wt%, and 4.52gaCNTs aqueous solution and 6g polystyrene (PS) microsphere aqueous solution (10wt%) were added to the beaker, and stirred for 3 hours , ultrasonically dispersed for 2 hours to form aCNTs / PS mixed solution as the dispersed phase. Pour 10mL of dispersed phase into No. 1 syringe on the dual-channel syringe pump, pour 50mL of simethicone into No. 2 syringe, control the adva...

experiment example 1

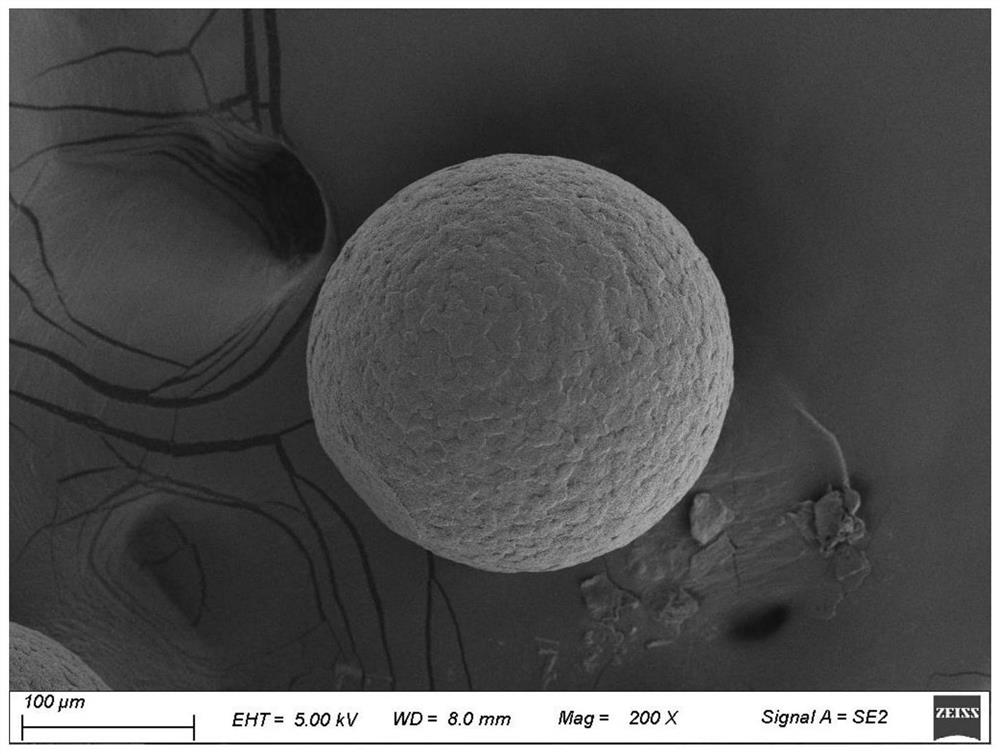

[0108] Experimental Example 1 SEM image of carbon nanotube microbeads / PMAA composite film as a whole

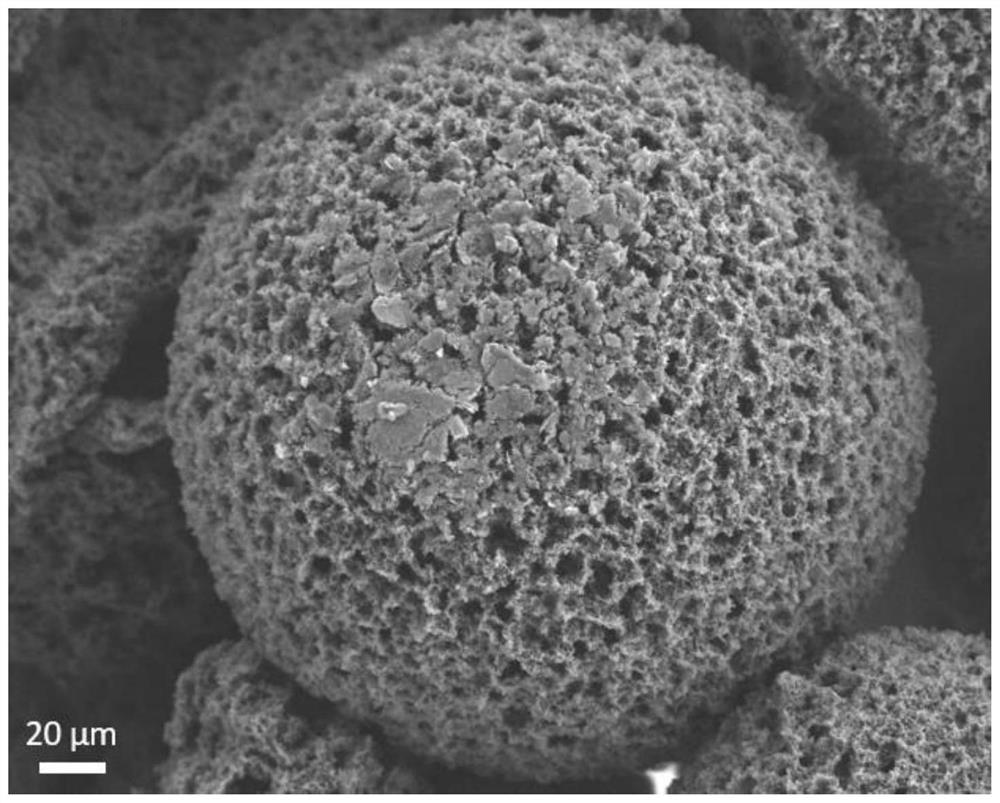

[0109] The samples used in this experimental example were prepared in Example 1. The SEM figure of the carbon nanotube / pore former microbead prepared in embodiment 1 before calcining, as Picture 1-1 , Figure 1-2 As shown, among them, Figure 1-2 for right Picture 1-1 The figure obtained after scanning the object in magnification, it can be seen that, Picture 1-1 When the surface of the ball in is scanned at a magnification, it can be observed that there are many small balls, and these small balls are polystyrene balls. After calcination, these pellets are all removed by calcination. The structure of carbon nanotube microbeads obtained after calcination is given by diagram 2-1 It can be seen that it is a hierarchical pore structure.

[0110] The overall scanning electron micrograph (300 times) of the sample made in embodiment 1 is as diagram 2-1 As shown, the carb...

experiment example 2

[0112] SEM image of the internal structure of the carbon nanotube microbead / PMAA composite film of Experimental Example 2

[0113] The samples used in this experimental example were prepared in Example 1.

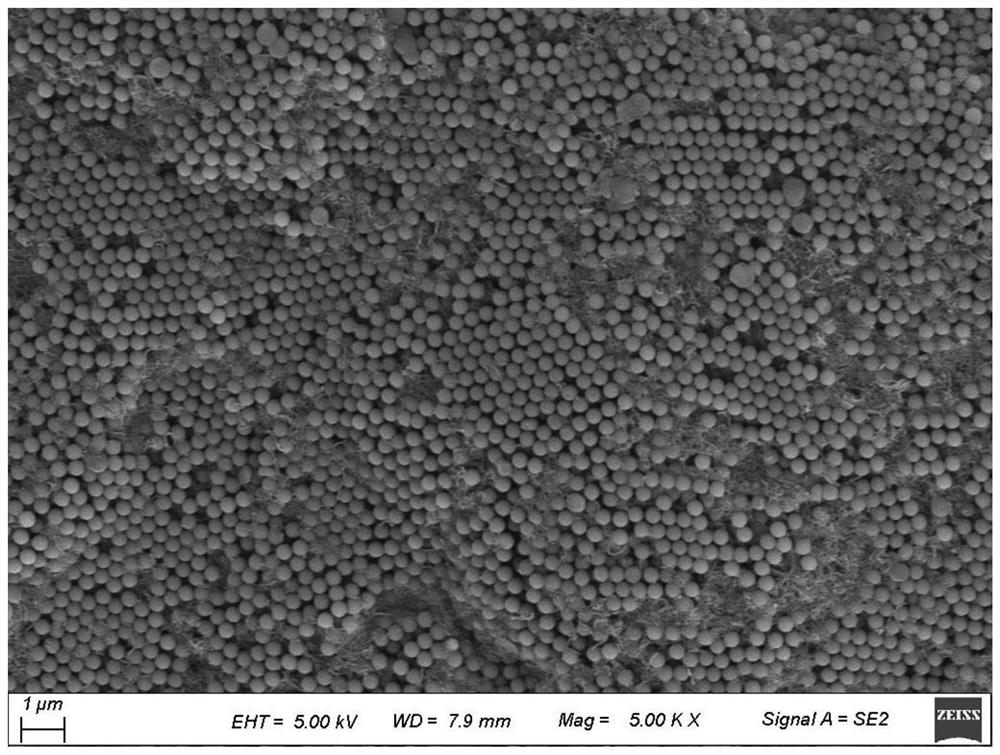

[0114] The internal scanning electron microscope picture (5000 times) of the sample that makes in embodiment 1 is as Figure 2-2 As shown, it can be seen that there is a rich interconnected pore structure inside the sample, and there are obvious pores with a diameter of 300-400nm and 1-10μm. At the same time, PMAA is filled on the porous carbon skeleton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com