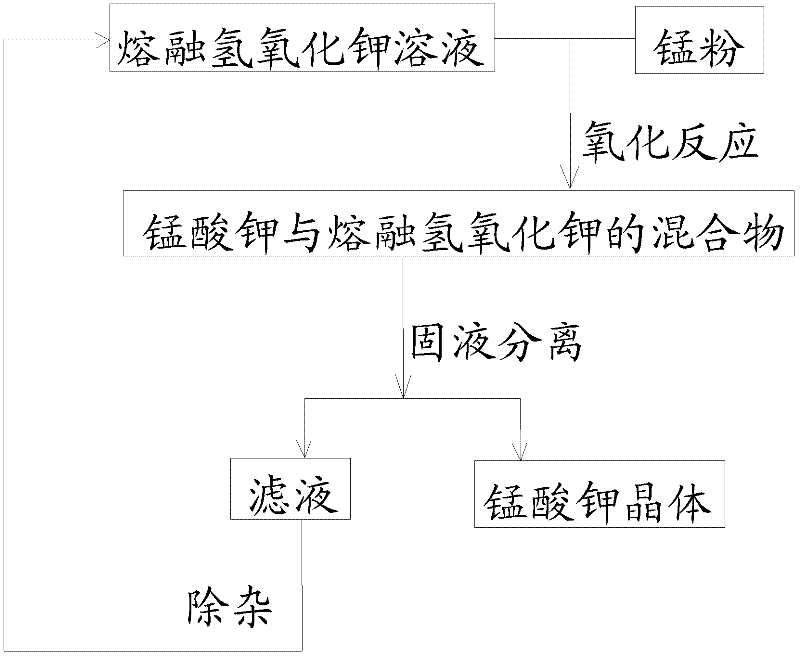

Process for preparing potassium manganate by liquid phase method

A technology for preparing potassium manganate and liquid phase method, applied in the direction of manganate/permanganate, etc., can solve the problems of liquid alkali heat loss, large processing capacity, etc., to improve quality, improve purity, and solve the problem of volume balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] First, make potassium hydroxide with a concentration of 60wt% and MnO in the state of heating and melting 2 Manganese powder with a content of 65 wt % and a particle size of 80 μm undergoes an oxidation reaction to obtain a mixture of potassium manganate and molten potassium hydroxide.

[0040] Then, pass the high-temperature feed liquid after the oxidation reaction through the ceramic filter plate, so that the molten alkali and most of the impurities and a small amount of potassium manganate pass through the filter plate, while most of the potassium manganate crystals remain on the filter plate. To increase efficiency, vacuum filtration is used.

[0041] The filtrate and the filter cake were cooled respectively and sent for sample analysis. As a result, the content of potassium manganate in the filter cake reached 92.5wt%, and the potassium manganate in the filtrate was 7.5wt% of the potassium manganate generated by the total reaction.

example 2

[0043] First, the concentration of 70wt% potassium hydroxide in the state of heating and melting with MnO 2 Manganese powder with a content of 48wt% and a particle size of 100 μm was oxidized to obtain a mixture of potassium manganate and molten potassium hydroxide.

[0044] The high-temperature feed liquid after the oxidation reaction passes through the ceramic filter plate, the molten alkali and most impurities and a small amount of potassium manganate pass through the filter plate, and most of the potassium manganate crystals remain on the filter plate. In order to improve efficiency, high temperature Press filter.

[0045] The filtrate and the filter cake were cooled respectively and sent for sample analysis. As a result, the content of potassium manganate in the filter cake reached 90.1wt%, and the potassium manganate in the filtrate was 9.9wt% of potassium manganate reacted in total.

[0046] Compared with Example 1, the time used for pressure filtration is shortened by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com