UV (Ultra Violet) hectograph printing ink used for printing

A technology of offset printing ink and photoinitiator, which is applied in the field of printing ink, can solve the problems of harmfulness to the human body and printing ink not meeting environmental protection requirements, and achieve the effects of preventing pollution, excellent adhesion performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

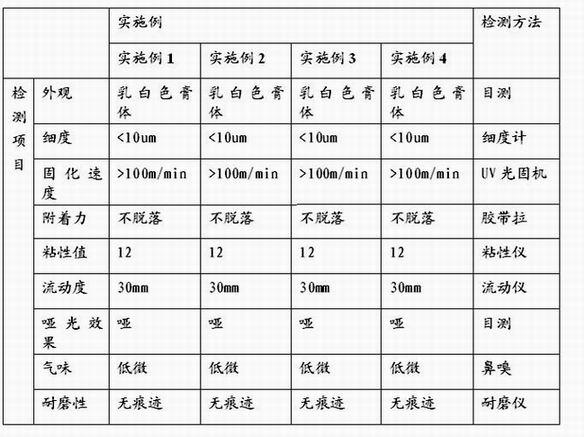

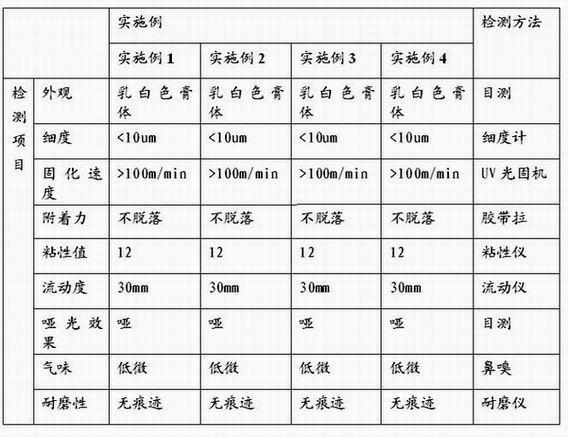

Embodiment 1

[0062] Take 10 parts (weight) of polyester acrylate, and add 35 parts (weight) of high-functional polyurethane acrylate, 15 parts (weight) of epoxy acrylate, and 10 parts (weight) of high-functional functional group acrylic monomer at a speed>600r / min. 2 parts (weight) of agent, 12 parts (weight) of photoinitiator, 16 parts (weight) of filler, high-speed dispersion and fully wet powder, three-roll machine grinding, fineness <10um, and the finished product.

Embodiment 2

[0064] Take 20 parts (weight) of polyester acrylate, and add 30 parts (weight) of high-functional polyurethane acrylate, 10 parts (weight) of epoxy acrylate, and 10 parts (weight) of high-functional functional group acrylic monomer at a speed>600r / min. 2 parts (weight) of agent, 12 parts (weight) of photoinitiator, 16 parts (weight) of filler, high-speed dispersion and fully wet powder, three-roll machine grinding, fineness <10um, and the finished product.

Embodiment 3

[0066] Take 30 parts (weight) of polyester acrylate, and add 25 parts (weight) of high-functional polyurethane acrylate, 5 parts (weight) of epoxy acrylate, and 10 parts (weight) of high-functional functional group acrylic monomer at a speed > 600r / min. 2 parts (weight) of agent, 12 parts (weight) of photoinitiator, 16 parts (weight) of filler, high-speed dispersion and fully wet powder, three-roll machine grinding, fineness <10um, and the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com