High-repetition-frequency passive-mode-locking ultrashort-pulse all-fiber laser

A high repetition rate, passive mode-locking technology, applied in the field of laser technology and nonlinear optics, can solve the problems of poor environmental stability, high production cost, complex structure, etc., and achieve the effect of narrow pulse width and high repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

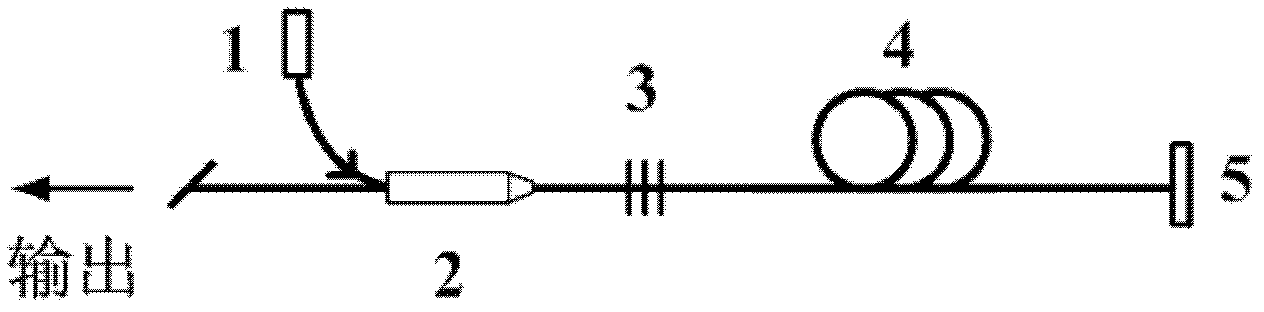

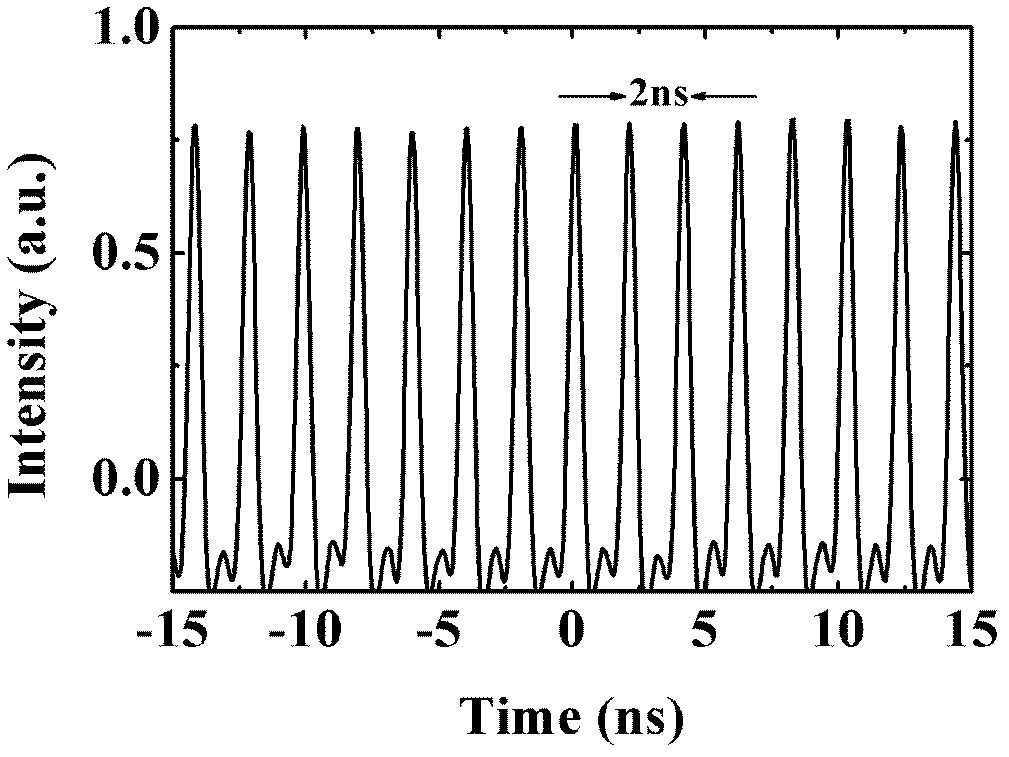

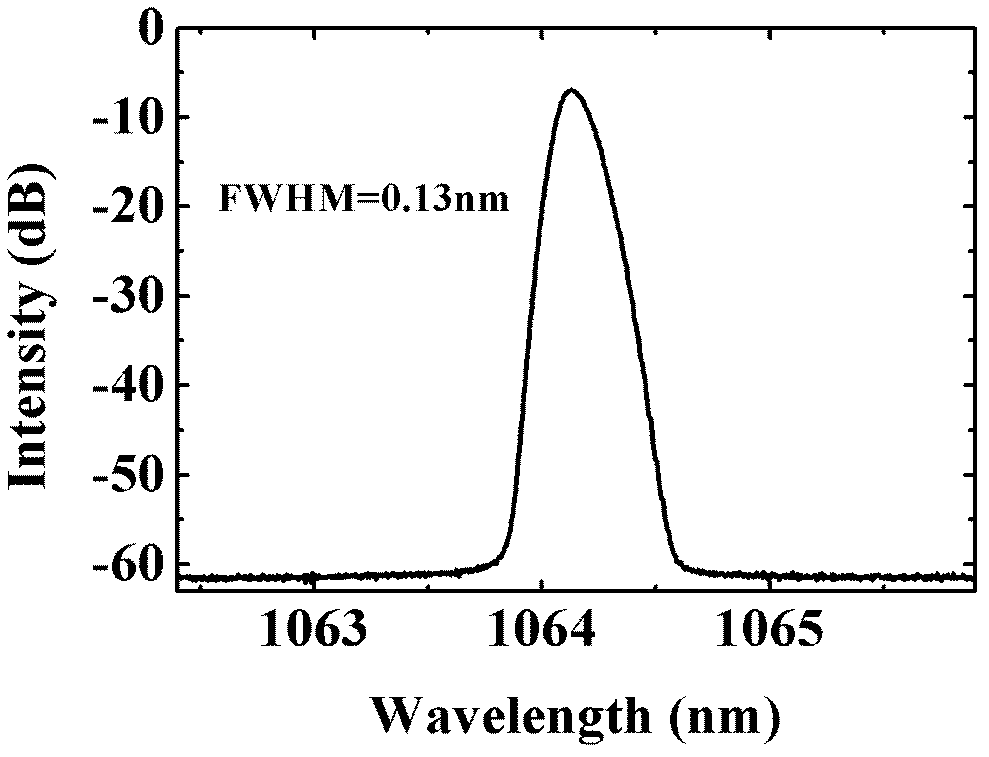

[0023] A high repetition rate passively mode-locked ultrashort pulse all-fiber laser structure such as figure 1 shown. Laser pump source 1 with a center wavelength of 974nm is connected to the pump input end of 980 / 1060 wavelength division multiplexer 2 with a maximum power of 500mW. The maximum output power of laser pump source 1 is 600mW; 980 / 1060 wavelength division multiplexer 2 The common end of the device 2 is connected to the fiber grating 3 with a reflectivity of 80%. The center wavelength of the fiber grating 3 is 1064nm, and the 3dB spectral bandwidth is 0.5nm; The 974nm band core pumping absorption rate is 1200dB / m; the other end of the ytterbium-doped fiber 4 is directly coupled with the reflective saturable absorber 5; the signal end of the wavelength division multiplexer 2 is used as the output end of the mode-locked laser pulse; A linear laser resonator is formed between the fiber grating 3 with an efficiency of 80% and the reflective saturable absorber 5. The ...

Embodiment 2

[0027] A high repetition rate passively mode-locked ultrashort pulse all-fiber laser structure such as Figure 5 shown. A laser pump source 1 with a central wavelength of 1550nm is connected to the pump input end of a 1550 / 2000 wavelength division multiplexer 2; the common end of a 1550 / 2000 wavelength division multiplexer 2 is connected to a 3m-long doped fiber 4; The other end of the miscellaneous optical fiber 4 is connected to a fiber grating 3 with a reflectivity of 90%, its center wavelength is 2000nm, and the 3dB spectral bandwidth is 2.0nm; the other end of the fiber grating 3 is used as the output end of the passive mode-locked laser pulse; 1550 / 2000 The signal end of the wavelength division multiplexer 2 is directly coupled to the reflective saturable absorber 5; a linear laser resonator is formed between the reflective saturable absorber 5 and the fiber grating 3 with a reflectivity of 90%; the high repetition rate Passively mode-locked ultrashort laser pulses will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com