Citric acid preparation method

A technology of citric acid and seeds, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low fermentation efficiency of citric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

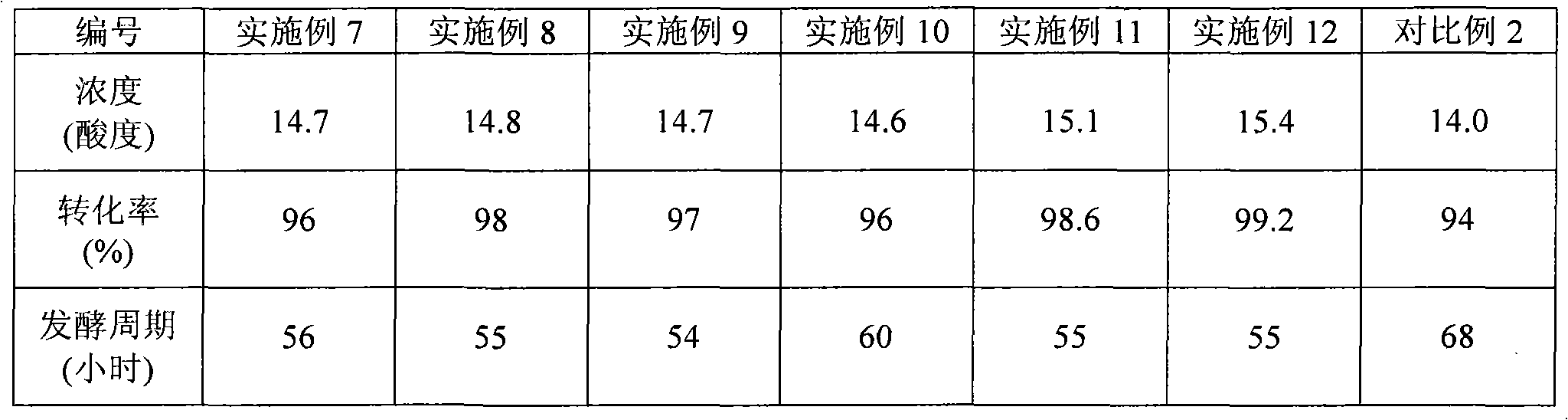

Examples

preparation example Construction

[0042] According to the present invention, the preparation method of the Aspergillus niger culture solution is not particularly limited, as long as the obtained culture solution can be suitable for the cultivation of Aspergillus niger, for example, the preparation method of the Aspergillus niger culture solution may include: Add amylase, heat up to 90-100°C at a rate of 20-150°C / hour and spray once at this temperature, flash after 5-30 minutes, and wait until the temperature drops to 80-95°C at this Enzymatically hydrolyzing the starch at high temperature for 90-140 minutes to obtain a liquefied liquid and diluting the total sugar to 5-20% by weight, then adding nitrogen source and sterilizing. The term total sugar refers to the total content of sugar contained in the enzymatic hydrolysis liquefaction liquid.

[0043] According to the present invention, in the starch slurry, the contents of starch and water and the pH of the slurry can be changed in a wide range, preferably, t...

Embodiment 1

[0053] This embodiment is used to illustrate the preparation method of citric acid provided by the invention.

[0054] (1) 100 parts by weight of harvested corn (moisture content: 14% by weight) was pulverized to obtain a pulverized product having an average particle diameter of 400 μm.

[0055] (2) Mix the pulverized product with water at a concentration of 25% by weight and then adjust the pulp, and add 20 enzyme activity units of amylase (Novozymes, a-amylase) relative to the dry weight of every gram of the pulverized product ), enter the ejector, and perform enzymolysis at 85°C and pH 5.5 for 100 minutes to obtain enzymolysis product A1. Among them, 80% of the A1 enzymatic hydrolysis product is filtered by a hydraulic plate and frame filter press to separate the enzymatic hydrolysis clear liquid and the enzymatic hydrolysis solid phase residue.

[0056] (3) Use the enzymolysis product obtained in step (2) and the separated enzymolysis clear liquid to configure the ferment...

Embodiment 2

[0060] This embodiment is used to illustrate the preparation method of citric acid provided by the invention.

[0061] Citric acid was prepared according to the method of Example 1, except that: the enzymolysis product A1 obtained in Example 1 was used to configure the fermentation broth, and the specific composition was 85 parts by weight of enzymolysis liquefaction clear liquid and 14.8 parts by weight of enzymolysis solid phase The residue (solid content: 30% by weight) and 0.2 parts by weight of urea were sterilized and added to the fermenter to obtain fermented liquid B2.

[0062] The enzymolysis liquefaction clear liquid obtained in Example 1 is diluted with water to 10% by weight of total sugar and put into the seed tank, and urea is added. The amount of urea added is 0.35% of the total weight of the seed tank culture solution, heated to 120°C for disinfection, and maintained After 20 minutes, the temperature was rapidly lowered to 36°C, and the Aspergillus niger strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com