Manufacturing method of icing-protection wind power generator blade

A wind turbine and anti-icing technology, which is applied in wind turbine components, wind engines, wind power generation, etc., can solve the problems of high thermal deformation temperature of resin, affecting the efficiency of blade surface heating, complex problems, etc., to achieve Good heating effect, extended service life, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

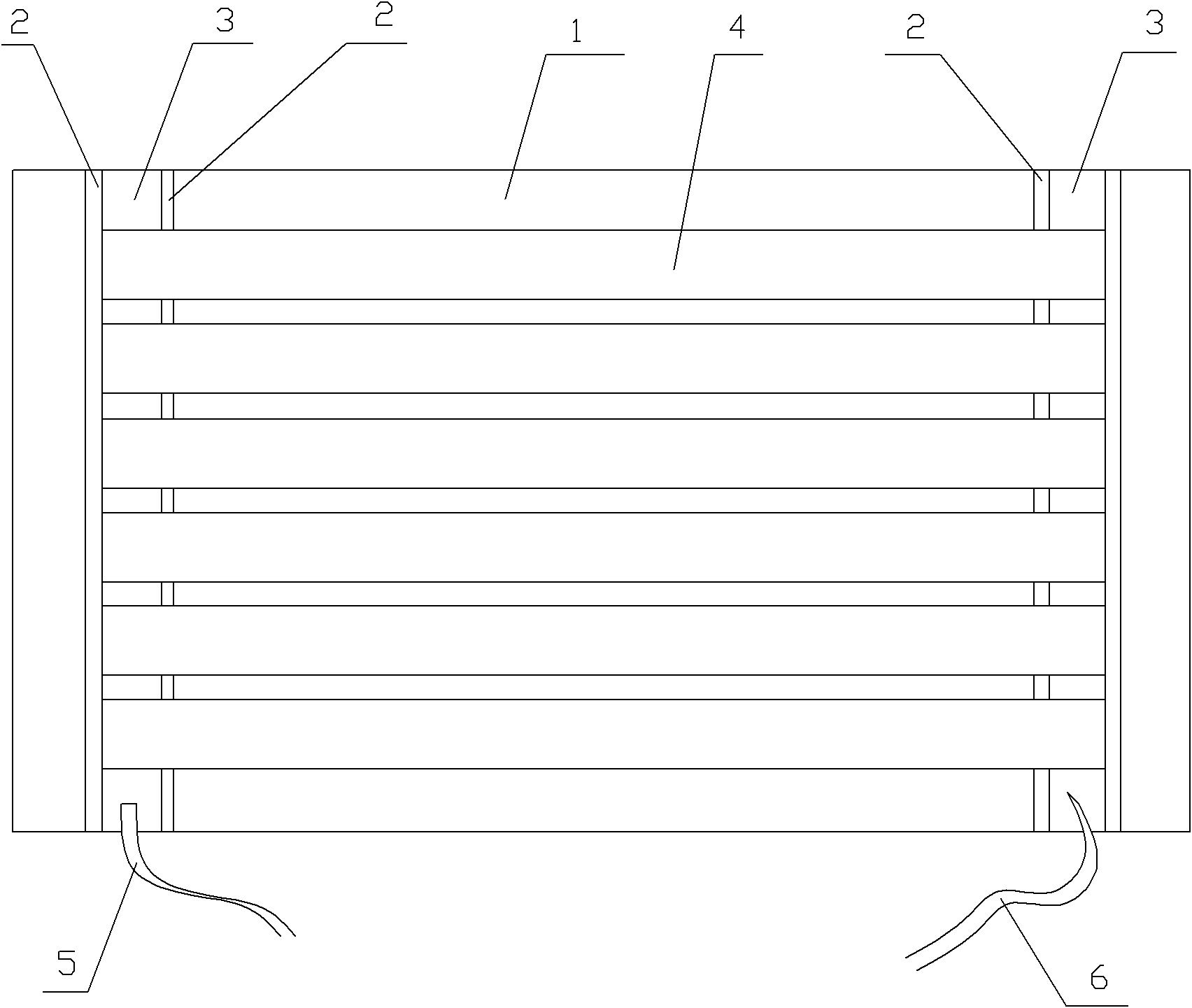

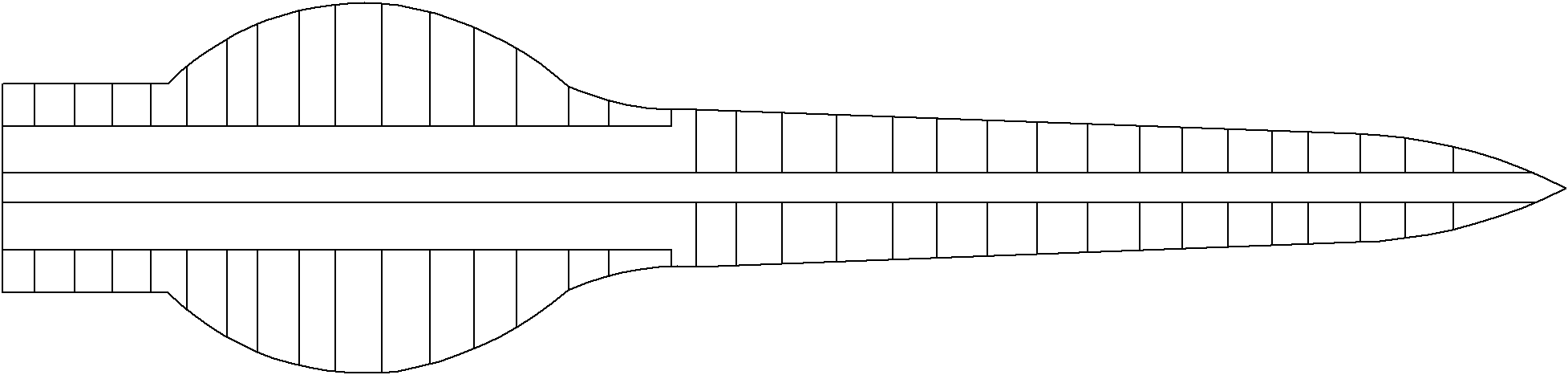

[0032] An anti-icing wind turbine blade, including a heating system, a control system, a power supply and a blade 1; the control system controls the power supply to be turned on and off; it is characterized in that: the heating system mainly includes a conductor 2 on the blade and heating coating 4; the blade 1 is covered with an insulating layer, the conductor 2 is arranged on the insulating layer, the heating coating 4 is covered on the conductor and the insulating layer, and the surface of the heating coating 4 is insulated layer coverage.

[0033] In practical application, when an ice layer appears on the surface of the blade 1 or the temperature is too low and needs to be heated, the control system controls the power to be turned on, the conductor 2 is energized, and the current is conducted to the heating coating 4, and the heating coating 4 starts to generate heat, and the surface temperature of the blade 1 It rises to melt the ice layer, and through the control of the ...

Embodiment 2

[0035] An anti-icing wind turbine blade, including a heating system, a control system, a power supply and a blade 1; the control system controls the power supply to be turned on and off; it is characterized in that: the heating system mainly includes a conductor 2 on the blade and heating coating 4; the blade 1 is covered with an insulating layer, the conductor 2 is arranged on the insulating layer, the heating coating 4 is covered on the conductor and the insulating layer, and the surface of the heating coating 4 is insulated layer coverage.

[0036] The heating system is more than one group, connected in parallel.

[0037] The heating system also includes a conductive medium layer 3, which covers the conductor and is located under the heating coating 4, increasing the stability and contact area between the heating coating 4 and the conductive medium. The conductor is copper foil, which further reduces the weight increase and does not cause changes to the shape of the blade....

Embodiment 3

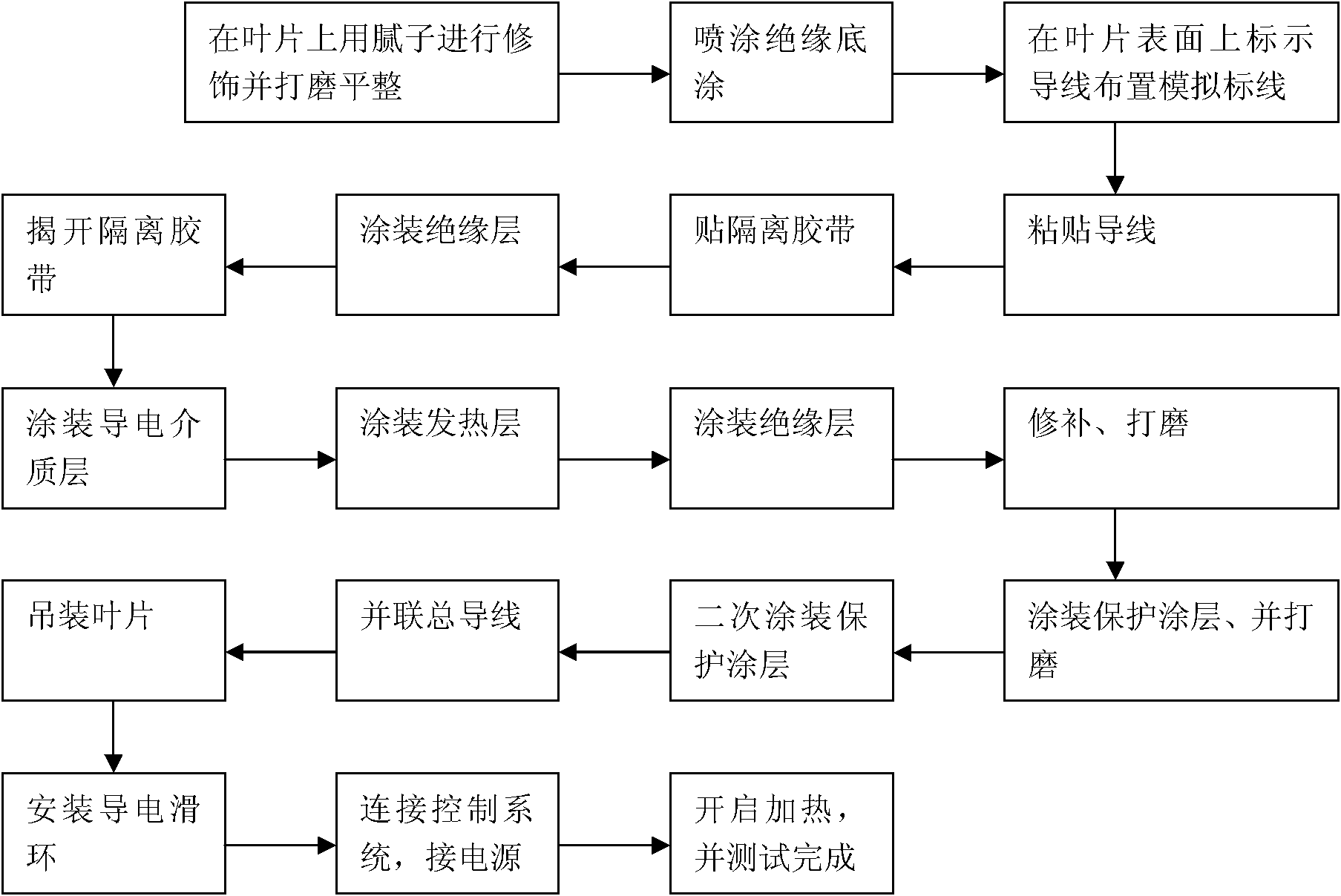

[0042] A method for preparing an anti-icing wind turbine blade, comprising the following steps:

[0043] 1) Preparatory work: hang the blade 1 to the predetermined position, and modify and polish the surface of the blade;

[0044] 2) Coating process: first coat the insulating layer on the surface of the blade 1, then paste the conductor 2 on the blade 1, coat the conductive medium layer 3 on the conductor 2, and coat the heat-generating coating on the conductive medium layer 3 4. Finally, an insulating layer is applied to the surface of the blade 1;

[0045] 3) Improvement work: repair and polish the above-mentioned blades after coating the insulating layer, and then apply a protective coating to blade 1;

[0046] 4) Installation test: After connecting the main wires in parallel, hoist the above-mentioned painted blades, install the rotating power connection device, connect the control system, connect the power supply, and conduct the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com