Angular pipe water circulating structure with complete forced upward flowing on heating surface

A heating surface, water circulation technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of stagnation and reverse flow, difficult maintenance, soaring wall temperature, etc., to reduce low-temperature corrosion and ash blocking, super power outage protection function, the effect of increasing the temperature of the metal wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

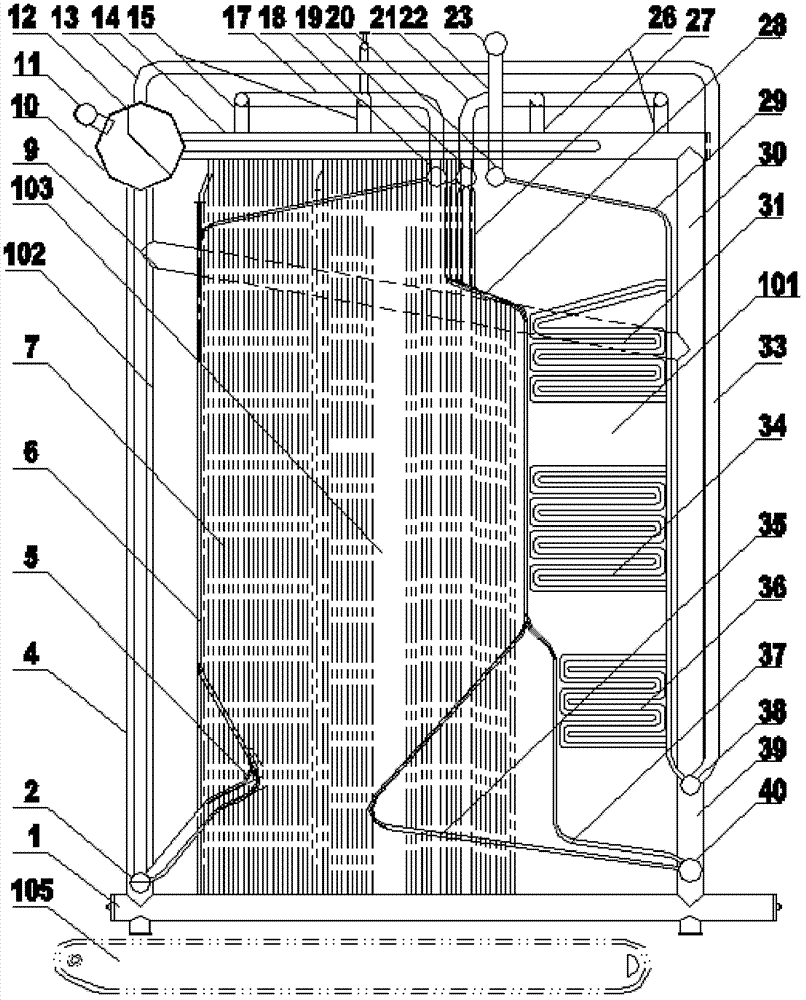

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0017] As shown in the attached figure, the angle tube water circulation structure with forced upward flow on the heating surface includes vertically attached to the outer wall of the front wall 102 of the boiler with the furnace 103 and the convection shaft 101 adjacent to each other vertically, and the corners on both sides are snapped together. The front wall and the corner pipes 4 on both sides of the outer wall of the front wall 102 are connected to the boiler drum 10 on the top of the front wall, and the corner pipes 4 on both sides of the front wall pass through the connecting pipe 9 The convection shaft vertically attached to the rear outer wall of the convection shaft 101 of the boiler and the corners on both sides are engaged with the convection shaft and the corner tubes 30 on both sides of the rear outer wall of the convection shaft 101, and the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com