Special connector for wind power optical cable assembly

A technology for optical cable components and connectors, which is applied in the field of special connectors for wind power optical cable components, can solve the problems of increasing the volume and weight of wind power special optical cable components, complex structures, and poor practicability, and achieve light weight, small size, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: refer to each accompanying drawing.

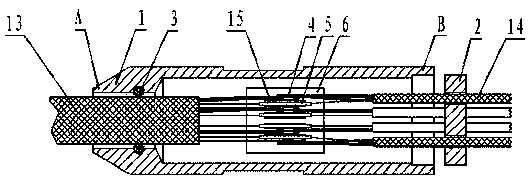

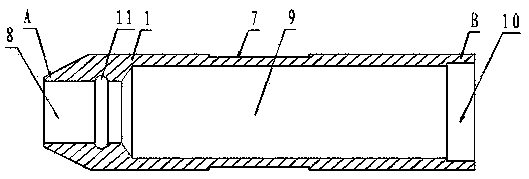

[0031] A special connector for wind power and wind power optical cable components, mainly composed of a hollow metal connector housing 1 with round holes of different sizes (the inner hole can be divided into an optical cable introduction hole 8, a connection protection placement hole 9 and a fiber outlet plug placement hole 10 three sections), a metal fiber outlet plug 2 with 6 pigtail outlet holes 12, a sealing ring 3, 3 metal connection cards 4, 3 heat shrinkable tubes 5, and a heat shrinkable tube bracket 6;

[0032] When in use, pass the 6-core wind power dedicated optical cable 13 to be connected through the optical cable introduction hole 8 of the hollow metal connector housing 1 with a sealing ring 3, leave a certain length of welding, and connect all 6 pigtails to be connected 14 passes through the pigtail outlet hole 12 of the metal fiber outlet plug 2, and also leaves a certain length of fusion splicing, and...

Embodiment 2

[0034] Embodiment 2: refer to each accompanying drawing.

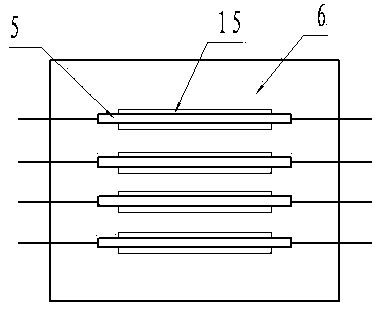

[0035] A special connector for wind power optical cable components, mainly composed of a hollow metal connector housing 1 (the inner hole can be divided into three sections: an optical cable introduction hole 8, a connection protection placement hole 9 and a fiber outlet plug placement hole 10), which is covered in a hollow metal connector housing. In one end of the connector housing 1, there is a group of metal fiber outlet plugs 2 with a total of 8 holes (i.e., pigtail outlet holes 12), and a sealing ring 3 is arranged in the other end of the hollow metal connector housing 1. Inside the hollow metal connector housing 1, there is a set of heat-shrinkable tube brackets 6 with a total of 8 heat-shrinkable tube fixing grooves 15 (for fixing the heat-shrinkable tube after heat shrinkage), a set of 8 heat-shrinkable tubes 5 in total, And a group of 8 metal connection cards 4 in total;

[0036]The other end of the hollow m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com