Developing agent and image forming apparatus

A developer and image technology, applied in the direction of developer, electric recording process using charge pattern, equipment for electric recording process using charge pattern, etc., can solve uneven distribution of toner surface, difficulty in uniform dispersion of additives, charge amount Uneven distribution and other problems, to achieve the effect of good charging characteristics, improved immobilization, and fast charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

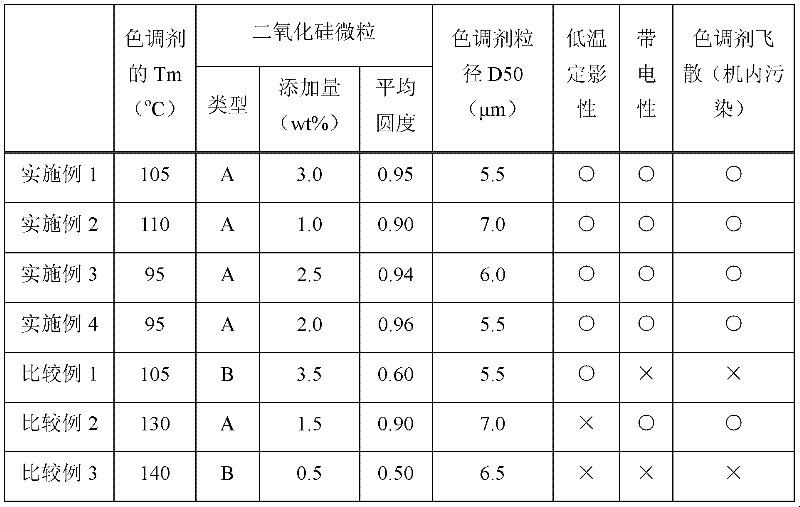

Embodiment 1

[0068] Polyester resin: (softening point Tm: 100°C to 120°C, glass transition temperature Tg: 54°C to 60°C) 85 parts by weight

[0069] Crystalline polyester resin (softening point Tm: 100°C to 120°C) 5 parts by weight

[0070] Ester wax 3 parts by weight

[0071] Coloring material (MA-100) 6 parts by weight

[0072] Charge control agent (polysaccharide compound containing aluminum+magnesium) 1 part by weight

[0073] After the above-mentioned materials were mixed via a Henschel mixer, they were melt-kneaded using a twin-screw extruder. After cooling the obtained molten kneaded product, it was coarsely pulverized using a hammer mill (Hammer Mill), then finely pulverized and classified using a jet mill, and finally obtained a volume average diameter of 5.5 μm, and a toner softening point Tm of Toner particles at 105°C.

[0074] A toner was produced by adding and mixing 3.0 parts by weight of sol-gel method silica fine particles having an average primary particle diameter of...

Embodiment 2

[0085] Polyester resin: (softening point Tm: 100°C to 120°C, Tg: 54°C to 60°C) 85 parts by weight

[0086] Crystalline polyester resin (softening point Tm: 100°C to 120°C) 0 parts by weight

[0087] Ester wax 8 parts by weight

[0088] Coloring material (MA-100) 6 parts by weight

[0089] Charge control agent (polysaccharide compound containing aluminum+magnesium) 1 part by weight

[0090] The above-mentioned material was prepared in the same manner as in Example 1 to obtain toner particles having a volume average diameter of 7.0 μm and a toner softening point Tm of 110° C.

[0091] With respect to 100 parts by weight of the toner particles, 1.0 parts by weight of a sol-gel method silica fine particle compound having an average primary particle diameter of 65 nm and an average circularity of 0.90, an average primary particle A toner was prepared using 2.0 parts by weight of hydrophobic silica having a diameter of 20 nm and 0.5 parts by weight of hydrophobic titanium oxide h...

Embodiment 3

[0096] Polyester resin: (softening point Tm: 100°C to 120°C, Tg: 54°C to 60°C) 78 parts by weight

[0097] Crystalline polyester resin (softening point Tm: 100°C to 120°C) 10 parts by weight

[0098] 5 parts by weight of ester wax

[0099] Coloring material (MA-100) 6 parts by weight

[0100] Charge control agent (polysaccharide compound containing aluminum+magnesium) 1 part by weight

[0101] The above-mentioned material was prepared in the same manner as in Example 1 to obtain toner particles having a volume average diameter of 6.0 μm and a toner softening point Tm of 95° C.

[0102] With respect to 100 parts by weight of the toner particles, 2.5 parts by weight of a sol-gel method silica fine particle compound having an average primary particle diameter of 60 nm and an average circularity of 0.94 and an average primary particle size of 2.5 parts by weight were added and mixed using a Henschel mixer. A toner was produced using 0.5 parts by weight of hydrophobic titanium o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com